Inclined Screw Conveyor

Inclined screw conveyors are used to convey a wide range of bulk materials from slow to free-flowing at large inclination angles (above 15°), which can simultaneously convey and lift products, saving space and reducing downtime.

Tilt angle: 0-60°

Length: 4-70 meters

Conveying capacity: 1.2-142m³/hour

Hopper volume: 200L

Application: It is suitable for inclined conveying of cement, fly ash, lime, flour, starch, food additives and other non-viscous powder and small granular materials.

Inclined screw conveyors are used to move material at an angle, typically operating from slightly above horizontal to 60 degrees from horizontal, the conveyor consists of a screw located in a tube or trough, inclined at an angle to the horizontal . The screw rotates inside the tube, pushing the material up the conveyor. It is usually used in various industries to convey materials such as grain, flour and chemicals, and can feed various powder or granular products into hoppers and silos.

Inclined screw conveyors require more horsepower: this is due to lifting the product and "re-feeding" the receding product.

Hangers should be eliminated: they create a "dead flow" area that is accentuated by the inclined conveyor. This often results in the use of longer screws, which require their own design considerations.

What is Maximum Angle for Screw Conveyor?

As shown in the figure, the inclination angle of the Inclined Screw Conveyor can be selected from any inclination angle between 0°-60°. At the same time, the Inclined Screw Conveyor can choose various designs such as shaft, shaftless, tubular, and U-shaped.

However, in order to ensure the conveying effect, when selecting the machine, it is necessary to choose according to the characteristics of different forms of Inclined Screw Conveyor.

The round tube shaft screw conveyor can be applied at any inclination angle of 0°-60°.

The cover of the U-shaped Inclined Screw Conveyor is a movable slot cover that is clamped on the casing with a cover buckle, which is relatively poor in sealing and has a large dead weight of the whole machine, which is only suitable for selection of inclination angles below 25°.

Due to the larger free space in the conveying pipeline, the shaftless screw conveyor is more likely to produce material retreat, so it is suitable for conveying angles below 45°.

Features and Benefits

1. Inclined conveying: It can be conveyed at a 60-degree inclination, and has the functions of conveying and lifting at the same time. It can be directly connected to the top silo or silo of the production line, or can be easily linked with screening machines, packaging machines, and mixers.

2. Uniform conveying: the motor power is large, and the transmission power is sufficient, which can realize inclined conveying, uniform conveying and no blockage.

3. Good sealing performance: During the whole conveying process, there will be basically no dust pollution, material overflow, etc., which improves the working environment.

4. Space saving: Can be designed to take up less space than other types of conveyor systems. They can be installed in areas with limited clearance or floor space.

5. Easy maintenance: easy to maintain and clean. They can be designed with features such as quick release hatches or removable covers for easy access and cleaning of screws and slots.

6. Safety: It can be equipped with protective cover, protective cover, emergency stop button and other safety devices to ensure safe operation.

Video

Stainless steel inclined screw conveyor

Shaftless inclined screw conveyor

Technical Parameters

| LS Type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed(r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery volume QΦ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| power Pd 1=30m(KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed(r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery volume QΦ=0.33(m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed(r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery volume QΦ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| power Pd 1=10m(KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| power Pd 1=30m(KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed(r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery volume QΦ=0.33(m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

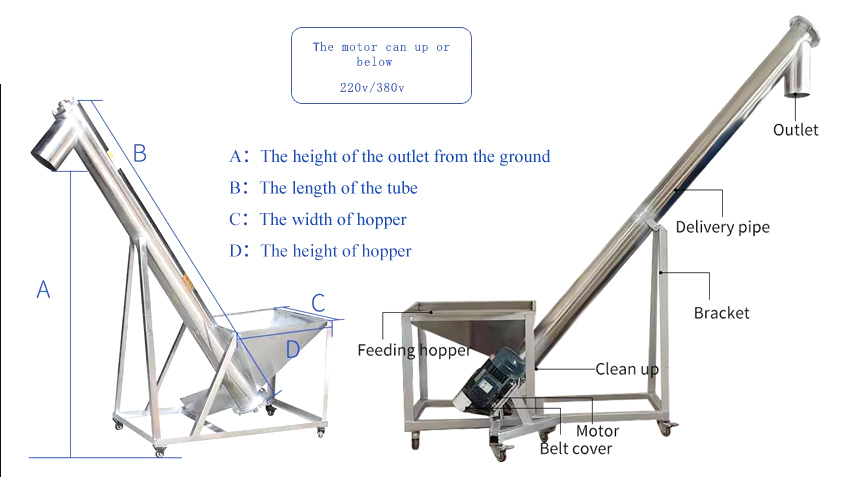

Structure of inclined screw conveyor

Available options

Inclined screw conveyors can be customized in many ways to meet specific needs and requirements. Here are some ways you can customize them:

1. Materials of Construction: Can be fabricated from a variety of materials depending on application requirements. Common materials of construction include stainless steel, carbon steel, and plastic.

2. Screw design: The screw design can be customized to optimize the conveying process. Screw diameter, pitch and speed can be adjusted to suit the material being conveyed and the required conveying capacity.

3. Tank body design: The tank body can be customized according to the materials to be conveyed and the required conveying capacity. Different trough designs are available, such as U-shaped or tubular, and can be made of different materials.

4. Inclination angle: The inclination angle of the conveyor can be customized to suit specific application requirements. The inclination angle is adjustable to optimize the conveying process and reduce energy consumption.

5. Accessories and options: Inclined screw conveyors can be equipped with a range of accessories and options according to application requirements. These include covers, guards, inspection windows, heating or cooling jackets, and variable frequency drives.

Application

Inclined screw conveyors are commonly used in various industries to move material at an angle. Following are some applications of inclined screw conveyors:

1. Food and beverage industry: used to transport food such as flour, sugar and grains. They are also used for handling liquids and semi-liquids such as sauces, syrups and dairy products.

2. Pharmaceutical industry: used to transport powdery, granular and other materials. They are commonly used in tablet production and other pharmaceutical manufacturing processes.

3. Chemical industry: used to transport powdery, granular, granular and other materials. They are commonly used in the production of chemicals, plastics and other products.

4. Agriculture: used to transport grain, feed and fertilizer. They are commonly used in grain storage and processing facilities, as well as feed mills and fertilizer plants.

5. Mining industry: used to transport ore, minerals, coal and other materials in the mining industry. They are commonly used in process plants and mining operations.

6. Waste Management Industry: Used in the waste management industry to process and move materials such as municipal solid waste, construction and demolition waste, and other types of waste.

Professional answers from manufacturers of Inclined Screw Conveyor——Inclination angle and conveying efficiency, solutions for declining conveying efficiency, selection points

1. Inclined Screw Conveyor's inclination angle and conveying efficiency

Theoretically speaking, the delivery angle of the Inclined Screw Conveyor can be arbitrarily selected between 0°-60°, but in actual use, as the inclination angle increases, the actual delivery effect of the material will inevitably deteriorate. After the inclination angle of the Inclined Screw Conveyor is greater than 15°, the conveying efficiency will decrease by 15% for every 5° increase.

In order to ensure the conveying effect, when selecting the machine, as a manufacturer, we give the following suggestions:

The conveying angle is 0-25°. According to the viscosity degree, easy winding degree and flow degree of the material, choose shaft, shaftless or round tube, U-shaped Inclined Screw Conveyor (almost no special restrictions).

The conveying angle is 25°-45°, and you can choose shaft or shaftless tubular Inclined Screw Conveyor.

The conveying angle is about 45° or above, choose the Inclined Screw Conveyor with shaft tube.

2. Four key points to solve the decline in transmission efficiency

Key point 1: Choose a motor with a higher power: a motor with a higher power provides greater power and solves the problem of material slippage that is prone to occur during material transportation at large inclination angles.

Point 2: Improve the traditional hanger: remove any obstacles that will block the progress of materials. The trouble caused by small obstacles will be magnified on the Inclined Screw Conveyor, causing more serious backflow or blockage of materials. If you need long-distance transportation, please contact us Engineers carry out the redesign of the machine.

Key point 3: Choose variable diameter screw and large diameter conveying pipe: Large diameter conveying pipe can accommodate more materials, and make up for material loss to a certain extent. In addition, (1/2 or 2/3) variable diameter screw can be The material in the conveying process provides more "foothold" and impetus.

Key point 4: Reasonable pressure at the feed inlet: When the Inclined Screw Conveyor's conveying inclination angle is greater than 50°, under the action of a high-power motor and a high-speed screw, light and thin materials or too little material will be "continuously punched out" by the screw blades It is difficult to enter the conveying pipeline, and it is necessary to exert sufficient pressure on the material at the feed inlet so that the material can enter the conveyor smoothly. At this time, the bottom of the bearing of the screw conveyor needs to bear a large pressure, which is easy to be damaged and needs to be inspected regularly.

3. How to choose a suitable Inclined Screw Conveyor?

Some selection tips for manufacturers:

1. What bulk materials do you need to convey? What is their material and state?

2. How much conveying volume do you need per hour and what is your feeding volume?

3. What is the height of the material conveyed to the next process, and what is the distance you expect?

4. Design conditions such as Inclined Screw Conveyor material, feeding and discharging conditions, working temperature, etc.?

...

We provide you with professional selection guidance, machine design and thoughtful after-sales service. Inquire now for more information.

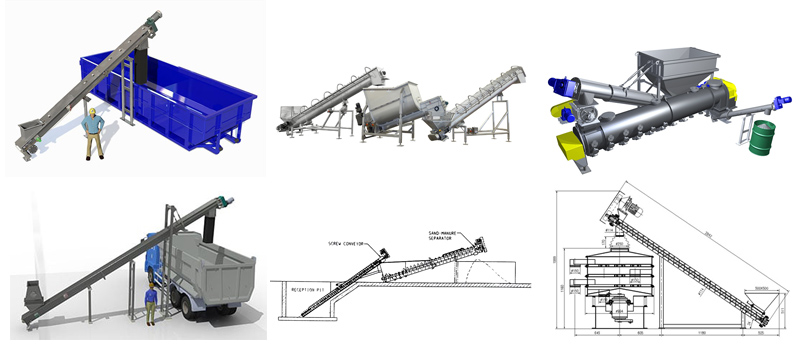

Cases of conveying solutions we provide

-

Conveying material: wheat

Recommendation: Inclined screw conveyor with hopper

Inclination:35°

-

Conveying material: flour

Recommendation: Stainless Steel Inclined Screw Conveyor with dust-free feeding station

Slope:35°

-

Conveying material: animal feed

Recommended: Stainless Steel Inclined Screw Conveyor

Slope:60°