Weighing and Batching System

Relying on the gravity of the powder and the forced action of the feeding working mechanism, the powder in the storage bin is discharged and continuously and evenly transported to the weighing equipment.

Weighing system: weighing sensor

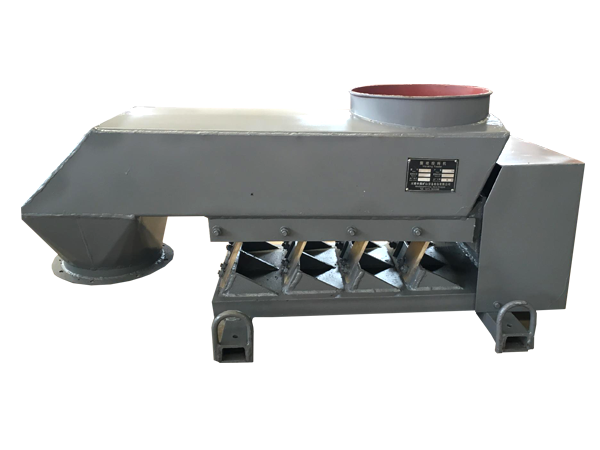

Feeding system: electromagnetic vibrating feeder

Capacity: 0.1-4 tons/hour

Material: carbon steel or stainless steel

Application: Applied in various industries, including food processing, pharmaceuticals, chemicals, building materials, etc., for accurate weighing and batching of raw materials to ensure accuracy and efficiency in the production process.

What is the Weighing and Batching System?

Weighing and batching system is specially designed for plastic, rubber and other industries that like to allocate less space for packaging equipment, and its fast and accurate weighing system is also suitable for other industries. Our GZV series adopts open frame, which is used in packaging industry And the easiest weighing system to maintain.

The feeding port of the electromagnetic vibrating feeder is generally softly connected with the discharging port of the storage bin. Excessive silo pressure will reduce the normal operation of the feeder, and the influence of silo pressure on the feeder must be minimized. The usual practice is to control the area of the silo vertically projected on the tank body to be smaller than the discharge port of the silo. The area is within 1/4 of the area, but it may cause the material to rise and arch in the storage bin; another method is to configure an inclined chute, and use the rear side plate of the inclined chute to bear most of the warehouse pressure; there is also a The method is to set a butterfly valve at the discharge port of the silo, and rely on the valve plate of the butterfly valve to bear part of the silo pressure.

Features and Benefits

The Weighing and Batching System provides high-precision automatic batching, uses hygienic stainless steel, saves space, reduces labor costs, and supports intelligent speed regulation to ensure efficient, accurate and hygienic industrial production processes.

Accurately weigh the feed

When approaching the set weight, it will automatically feed slowly to ensure accurate weighing.

Made of clean and hygienic stainless steel

Standard polished stainless steel means safe, hygienic and easy to clean. Ideal tool for food, chemical, pharmaceutical

Space-saving design

Weighing and Batching System can be placed arbitrarily in a small space without careful arrangement

Save labor cost

Weighing and Batching System automatically weighs and is fast and accurate, eliminating the trouble of manual weighing and improving the efficiency of batching

Three-speed speed regulation, instant stop and instant start

The Weighing and Batching System is powered by electromagnetism, which can realize fast speed regulation without gear limit and instantaneous switch, which is more precise and intelligent.

Weighing and Batching System operation display

Weighing and Batching System distributes screws by weight

This is a set of standard Weighing and Batching System, which can transport the screws into the carton according to the set weight, and stop feeding when the specified weight is reached. It is suitable for the weighing of various bulk materials, and is more accurate and faster.

Weighing and Batching System Dispensing activated carbon by weight

In the Weighing and Batching System to distribute activated carbon by weight, the Vibrating Feeder has added baffles around it to reduce the scattering of powdered activated carbon during the feeding process. It has adjustable conveying speed and weighing weight, which is better than manual feeding. Dosing is faster and more precise.

Weighing and Batching System dual channel distribution of seeds by weight

The stainless steel design makes it ideal for conveying food, which means safety and hygiene. In this Weighing and Batching System, the Vibrating Feeder has a dual feeder design, which can weigh two bulk materials at the same time. At the same time, the Weighing and Batching System is equipped with a Bucket elevator to send the materials into the silo of the Weighing and Batching System, and automatically feed the materials. The material is automatically weighed.

What is working principle?

The core of the Weighing and Batching System is the feeding system and the weighing system. The feeding system is generated by the electromagnet and the electric coil in the electromagnetic vibrator after the electromagnetic is energized. After being damped by the shock absorber, the armature, connecting fork and other structures It is transmitted to the feeding trough, so that the whole machine produces back-and-forth reciprocating and throwing motions, so that the machine can self-feed.

The function of the weighing system is to cooperate with the feeding system to control the weight of the feeding material, and reduce the feeding amount and speed when the feeding amount is close to the preset standard, so as to achieve the purpose of accurate feeding.

Weighing and Batching System model

| Model | GZV1 | GZV2 | GZV3 | GZV4 | GZV5 | |

| Capacity (tons/hour)5 | 0.1 | 0.5 | 1 | 2 | 4 | |

| Double amplitude (mm) | 1.5 | |||||

|

Frequency (times/minute) |

3000 | |||||

| Power (W) | 5 | 8 | 20 | 25 | 30 | |

| Control equipment | Model | Model:XKZV-Ⅱ | ||||

| Control method | Controlled Half-Wave Rectifier | |||||

|

Tension (V) |

220 | |||||

|

Frequency (Hz) |

50 | |||||

|

Current (A) |

0.08 | 0.12 | 0.15 | 0.2 | 0.25 | |

| Weight | 4 | 7 | 12 | 18 | 27 | |

What is the Weighing and Batching System used for?

The Weighing and Batching System utilizes high-precision sensors and automated control technology to accurately weigh, proportion, and mix a variety of raw materials, ensuring consistent product quality and production efficiency. Its core functions include automatic metering, data logging, error alarms, and recipe management, minimizing human error, reducing raw material waste, and improving production compliance. Furthermore, the system can be integrated into production lines, supporting remote monitoring and data analysis to optimize production processes, and is suitable for both continuous and batch production.

Accurate Measurement:Ensures precise weighing of each ingredient to meet the required specifications.

Batching: Automatically controls the amount of each ingredient added to the mix according to predefined recipes.

Data Logging: Records the weights and batching processes for quality control and compliance with industry standards.

Recipe Management:Allows for easy adjustments and storage of multiple recipes for different products.

What are the components of Structure of Weighing and Batching System?

Weighing and Batching System silo, electromagnetic vibrating feeder, weighing machine, controller and other parts.

The electromagnetic vibrating feeder is mainly composed of a material trough, an electromagnetic vibration exciter and a shock absorber. The trough is a bearing member, used to bear the material from the storage bin, and transport it to the weighing equipment through electromagnetic vibration. The electromagnetic vibrator is a component that generates energy for reciprocating vibration in the trough. The function of the shock absorber is to reduce the vibration force transmitted to the foundation or frame, and the feeder is suspended on the wall of the storage bin or on the building components through the shock absorber.

The controller controls the weight of the material. When the weight of the material reaches the set value, the system will automatically stop.

option content

The Weighing and Batching System offers a variety of sealed feed chutes, including square, round tube, V-groove, and double chutes, to meet the needs of diverse material characteristics. Equipped with a high-performance motor for ample power, the system offers flexible drive options, supporting motor-driven, manual, and fully automatic control modes. PLC programming enables precise metering and batch management. Furthermore, a circular feed hopper design, special materials for enhanced durability, a screen installed in the feed trough to ensure material purity, and an elevated base to accommodate diverse installation scenarios ensure efficient and accurate batching.

What are the applications of Weighing and Batching System?

The Weighing and Batching System is used for precise batching and mixing in industrial production. It can realize automated weighing, batching and data recording, improve production efficiency and product quality, reduce human error, and is suitable for batch processing of materials such as powders, granules, and liquids.

Weighing and batching system plays a crucial role in ensuring accurate and efficient material handling and batching processes in various industries.

Food and Beverage Industry: Accurately measuring ingredients for recipes, such as flour, sugar, and spices.

Chemical Industry: Precisely mixing chemicals for various formulations.

Pharmaceutical Industry: Ensuring accurate dosages of active ingredients in medications.

Construction Industry: Mixing concrete and other building materials.

Agriculture Industry: Blending fertilizers and animal feed.

Solutions by Industry

-

Weighing Machine with Vibratory Feeder Bulk Biscuit Weighing Feeder

-

Weighing Machine with Vibratory Feeder Bulk Nuts Weighing Feeder

-

Weighing Machine with Vibratory Feeder Bulk Peanut Weighing Feeder

-

Weighing Machine with Vibratory Feeder Bulk Powdered Sugar Weighing Feeder

Weighing and Batching System Supplier

Leveraging years of industry experience, our Weighing and Batching System utilizes high-precision sensors and advanced control technology to ensure batching tolerances within ±0.1% to 0.5%, meeting the stringent requirements of industries such as building materials, chemicals, and food. Our systems support customizable designs and incorporate intelligent anti-blocking and energy-saving technologies to significantly improve production efficiency and stability. Furthermore, we provide comprehensive services, from solution design to after-sales maintenance, to ensure the long-term, reliable operation of our customers' production lines. Inquiries are welcome!