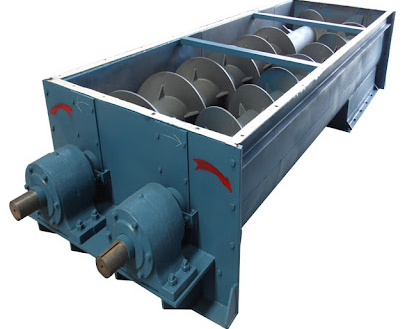

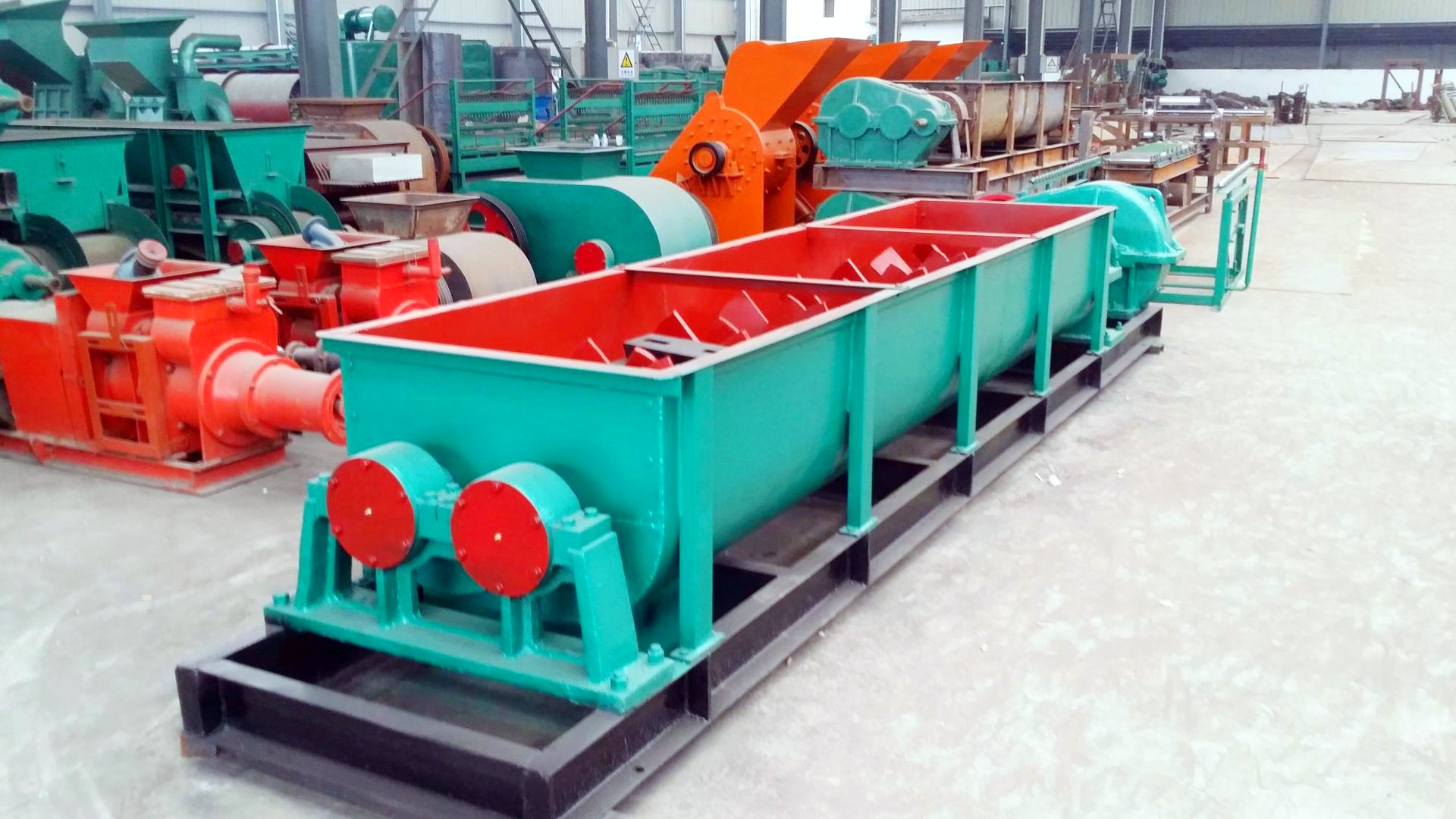

Twin Screw Mixer

The Twin Screw Mixer can mix a variety of materials, has a power range of 5.5-90kW, a capacity of 50-5000L, and a price of approximately $10,000-$200,000.

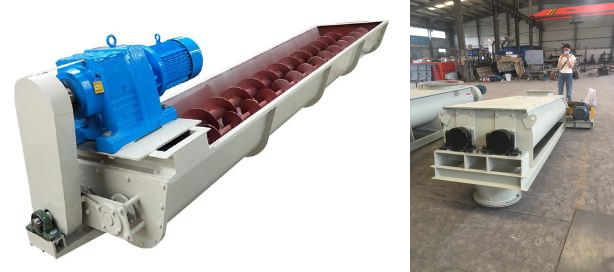

Length: 60 meters

Conveying volume: 458 cubic meters/hour

Power: 1.1-24.4 kilowatts

Twin screw mixer are available in both shafted and shaftless configurations. Shafted mixers are ideal for conveying heavy materials, while shaftless mixers prevent entanglement and offer enhanced self-cleaning capabilities. They offer a wide range of processing capacities, from small laboratory units to large industrial equipment capable of handling tens of tons per hour. They achieve a high degree of mixing through the counter- or co-rotating shear, convection, and diffusion effects of the two screws, enabling rapid and uniform mixing. They are suitable for both solid-solid and solid-liquid mixing.

-

What is a twin screw mixer?

Twin screw mixer is an efficient mixing equipment that is widely used for uniform mixing of powder, granules, fibers or flaky materials. It is especially suitable for places with high conveying capacity requirements, complex material characteristics, or the need to mix during the conveying process, such as medium and high viscosity and thixotropic materials. The rotary motion of the two screw shafts realizes efficient mixing, stirring, conveying and other functions. It is widely used in mixing equipment in the chemical, food, pharmaceutical, building materials and other industries. Its core design realizes efficient and uniform material mixing through the coordinated motion of the two screw shafts.

Video of twin screw mixer

What are the advantages of twin screw mixer?

Twin Screw Mixer meets the technical requirements of mixing during the conveying process, thus solving problems such as poor material fluidity, easy agglomeration, accumulation, and insufficient conveying capacity.

Solve the problem of conveying materials with poor fluidity and easy to agglomerate

When the two screw shafts rotate in opposite directions, the shear force and extrusion force they generate can effectively destroy the agglomeration and agglomeration in the material, keeping it loose and thus smoothly conveyed. This is especially important for conveying wet, sticky or easily agglomerated materials (such as wet sludge, certain chemical powders). The synergistic effect of the twin screw mixer can more actively push the material forward, reduce the retention and blockage of the material in the trough, and ensure the continuity and stability of the conveying.

Deal with material accumulation and bridging during the conveying process

The counter-rotating screw shafts not only convey the material, but also play a stirring role, which can effectively disturb the material and prevent it from forming a stable "bridge" structure in the trough, thereby avoiding conveying interruptions. The structure of the twin screw mixer helps to distribute the material more evenly and reduce the possibility of accumulation caused by excessive local pressure.

Solve the problem of insufficient conveying capacity of a single shaft

The two screw shafts work at the same time, and can convey more materials under the same trough size, significantly improve the conveying efficiency, and meet the needs of larger conveying volume. The two screw shafts push the materials synchronously, and the conveying capacity is increased by 30%~50%, which is suitable for the large-scale conveying needs of the mining and building materials industries.

Responding to the process requirements of mixing while conveying

For occasions where simple mixing is required during the conveying process (for example, mixing two or more powders, or adding a small amount of liquid to the powder), the counter-rotating twin screw mixer can achieve preliminary mixing while conveying, simplifying the process flow and reducing equipment investment.

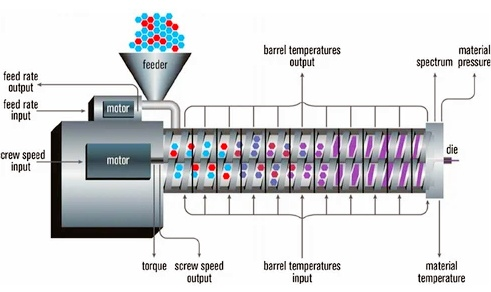

What is the working principle of twin screw mixer?

The twin screw mixer uses the spiral blades to push the material in the trough through the synchronous or reverse rotation of the two screw shafts, so that it moves along the axial direction, thereby realizing the conveying of materials.

① Co-rotation: When the two screw shafts rotate in the same direction, the materials are usually transported forward together, which can improve the conveying capacity.

② Reverse rotation: When the two screw shafts rotate in opposite directions, the materials can be mixed or stirred while being transported to prevent the materials from agglomerating or bridging, and the materials with poor fluidity can be transported more evenly.

Structure of twin screw mixer

Double screw shaft: The two spiral blades are arranged in a symmetrical or staggered manner, usually rotating in opposite directions to form a convection mixing effect. The pitch, diameter and rotation speed of the spiral blades can be adjusted according to the material characteristics (such as particle size and viscosity).

Drive system: The motor drives the spiral shaft through the reducer, and the frequency converter can achieve stepless speed regulation.

Mixing chamber: The chamber is mostly U-shaped or cylindrical, with a smooth inner wall or an anti-stick coating, which is convenient for material flow and cleaning.

Sealing and support: The shaft end adopts a mechanical seal or a packing seal to prevent material leakage; the bearing seat supports the spiral shaft to ensure smooth operation.

Twin Screw Mixer Models

|

Specifications Specifications |

Main technical performance |

Drive |

Drive |

weight (kg) |

|||

|

Diameter |

Length(m) |

Output (cement) t/h |

Speed (min) |

Reducer |

Reducer |

Motor |

|

|

model |

speed ratio |

power (kw) |

|||||

|

U200 |

-10 |

9 |

60 |

ZQ250 |

23.34 |

1.1 |

726 |

|

U200 |

-20 |

9 |

60 |

ZQ250 |

23.34 |

1.5 |

1258 |

|

U250 |

-10 |

15.6 |

60 |

ZQ250 |

23.34 |

2.2 |

960 |

|

U250 |

-20 |

15.6 |

60 |

ZQ250 |

23.34 |

3 |

1750 |

|

U300 |

-10 |

21.2 |

60 |

ZQ350 |

23.34 |

3 |

1373 |

|

U300 |

-20 |

21.2 |

60 |

ZQ350 |

23.3 4 |

4 |

2346 |

|

U400 |

-10 |

51 |

60 |

ZQ400 |

23.34 |

5.5 |

1911 |

|

U400 |

-20 |

51 |

60 |

ZQ500 |

23.34 |

11 |

2049 |

|

U500 |

-10 |

87.5 |

60 |

ZQ400 |

23.34 |

7.5 |

2381 |

|

U500 |

-20 |

87.5 |

60 |

ZQ650 |

23.34 |

18.5 |

5389 |

|

U600 |

-10 |

134.2 |

45 |

ZQ750 |

23.34 |

22 |

3880 |

|

U600 |

-10 |

134.2 |

45 |

ZQ850 |

23.34 |

55 |

7090 |

The difference between twin screw mixer and single-axis screw conveyor

|

Features |

Twin screw mixer |

single-axis screw conveyor |

|

Image |

|

|

|

Number of screw shafts |

usually two parallel screw shafts |

only one screw shaft |

|

Conveying capacity |

usually has higher conveying capacity in the same space |

relatively low conveying capacity |

|

Applicable materials |

more suitable for materials with high viscosity, easy to agglomerate or poor fluidity |

applicable to powdery and granular materials with good fluidity |

|

Mixing function |

can have both mixing or stirring functions when rotating in reverse |

usually only has conveying function, and the mixing effect is limited |

|

Preventing blockage |

reverse rotation can more effectively prevent material blockage |

easy to cause blockage due to material adhesion or bridging |

|

Application scenarios |

environmental protection, chemical industry, food and other occasions where difficult to convey materials or need to be mixed |

grain, oil, feed, building materials and other occasions where conveying capacity is not high and material fluidity is good |

What are the applications of Twin Screw Mixer?

Twin Screw Mixer is a device that conveys pipes through the rotation of two screw conveying screws. It is widely solicited in multiple industries to improve the ability to effectively handle viscous, easy to spiral or mixed conveying.

Chemical and building materials industry: conveying powdered materials such as cement, lime, gypsum powder, etc., to prevent dust and leakage, and used in scenes where uniform feeding is required, such as fertilizers and plastic particles.

Food and pharmaceutical fields: conveying food raw materials such as flour, powdered sugar, and milk powder, in accordance with standards (such as stainless steel). Conveying materials that require precise measurement, such as tablets and additives.

Environmental protection and waste treatment: conveying viscous or water-containing materials such as sludge and biomass particles, and conveying pre-treated waste in waste incineration plants.

Agriculture and feed processing: conveying grains and feed raw materials, supporting continuous operation of large-scale production lines, and the double screw design can achieve preliminary mixing of materials during the conveying process, which is suitable for processes that require uniform mixing.

Twin Screw Mixer Customer Case Studies

In the new energy materials sector, a battery company uses a Twin Screw Mixer for homogenous mixing of lithium iron phosphate cathode materials. The device's shearing and dispersing capabilities ensure the perfect blending of nanopowders and conductive agents.

In the chemical industry, a Twin Screw Mixer is being introduced for the production of high-end sealants. Its precise temperature control and efficient mixing address the problem of uneven dispersion of additives in high-viscosity materials.

The food processing industry uses a Twin Screw Mixer for processing nutritional powders. Its gentle mixing process effectively protects heat-sensitive nutrients, while its zero-dead-spot design ensures uniform distribution of flavors.

Twin screw mixer price

A small laboratory twin screw mixer costs approximately $10,000 to $30,000. Standard mid-sized industrial-grade equipment typically ranges from $50,000 to $150,000. Large, customized, or high-end models using exotic alloys can cost around $300,000. Costs vary depending on throughput, motor power, corrosion resistance, and control system complexity.

If you need to know the specific price of twin screw conveyor, you can contact Dahan Machinery's conveyor manufacturer or supplier to obtain a detailed quotation plan based on your needs.