Belt Conveyor Fertilizer

Belt conveyor fertilizer is a mechanical equipment used to transport fertilizers (such as organic fertilizers, inorganic fertilizers, compound fertilizers, etc.), which is widely used in fertilizer plants, agricultural production, wishouses and packaging production lines. It transports fertilizers from one place to another through a continuously running belt structure, suitable for pipelines in bulk, bagged or granular wishouses.

Conveying capacity range: 30-300 tons/hour

Conveying length: 230 meters

What is a belt conveyor fertilizer?

The belt conveyor fertilizer is a conveying system specially used for conveying and handling fertilizers or fertilizer-related products. It is a continuous conveying system widely used in agriculture and industry to efficiently move fertilizers from one location to another, such as from a packaging workshop to a loading point, or from a storage wishouse to a fertilization equipment. The equipment usually consists of a conveyor belt, a drive device and a support structure, and can convey fertilizers horizontally, inclined or vertically.

Applicable materials for belt conveyor fertilizer

Belt conveyor fertilizer is designed to handle various types of fertilizers, including granular fertilizers, powdered fertilizers and mixed fertilizers. Belt conveyor fertilizer is wear-resistant and corrosion-resistant, and is widely used in agricultural production, fertilizer production plants, distribution centers and other places that require efficient and reliable fertilizer transportation.

Types of fertilizer conveyor belts

Fertilizer conveyor belts generally refer to conveyor belt equipment used to transport fertilizers, which is commonly seen in agricultural fertilizer production, compound fertilizer processing, and fertilizer storage and loading and unloading. Fertilizer conveyor belts can be divided into many types according to different transportation requirements and materials.

①Classification by material

|

Material type |

Picture |

Main features |

Applicable fertilizer type |

Applicable environment and scenario |

|

Ordinary rubber belt conveyor |

|

Wear-resistant, strong load-bearing capacity, suitable for medium working conditions; not acid- and alkali-resistant |

Compound fertilizer granules, organic fertilizer dry material |

Fertilizer processing plant production line, short-distance transportation |

|

PVC conveyor belt |

|

Lightweight, smooth surface, waterproof, easy to clean; temperature resistance is relatively general |

Lightweight granular fertilizer, small bag fertilizer after packaging |

Packaging line, short-distance transportation, loading platform |

|

PU belt conveyor |

|

Food grade material, oil-resistant, corrosion-resistant, non-toxic |

Organic fertilizer, bacteria Fertilizer, fertilizer that needs a clean environment |

Organic fertilizer workshop, fine production line |

|

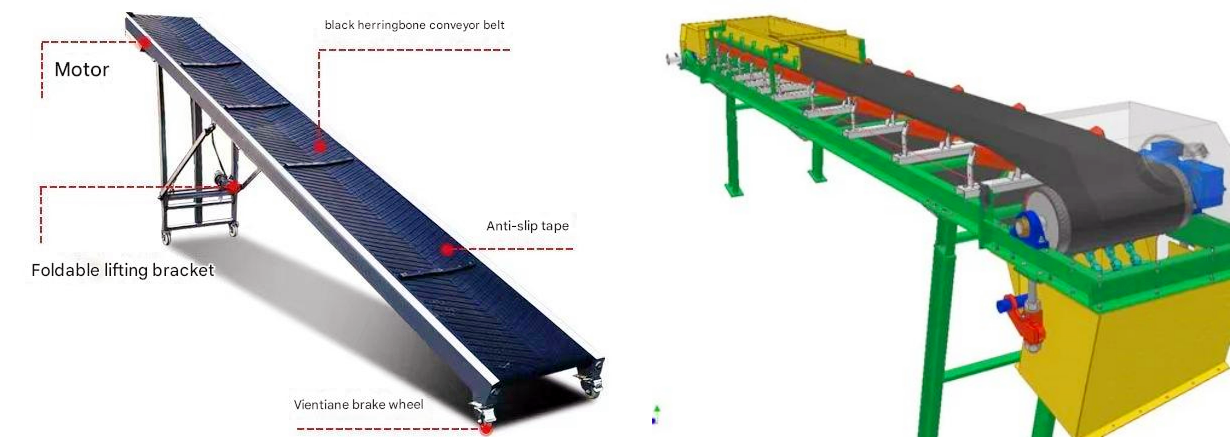

Pattern belt conveyor |

|

Surface with pattern to increase friction and prevent slippage |

All types of fertilizers, especially inclined conveying |

Inclined lifting section, stacking and loading |

|

Skirt baffle belt conveyor |

|

With high sides and partitions, suitable for large-angle conveying |

Powder, granules, organic fertilizer, etc. |

Vertical or nearly vertical conveying occasions, such as silo loading |

②Classify according to conveying direction

Horizontal belt conveyor: Move items along the horizontal plane, and a variety of goods can be transported during manufacturing, wishousing and distribution. Different belt materials (such as rubber, PVC, fabric) and designs (flat belt, modular, roller bed) can meet various needs. They is commonly used for assembly lines, packaging and long-distance transportation of goods within factories.

Inclined belt conveyor: Move materials up or down at a certain angle. They help overcome altitude changes and optimize space by utilizing vertical isas. They is used in industries such as manufacturing, mining, agriculture and packaging to transport bulk materials, loose items or packaged goods between different levels.

Vertical conveyor: Moving materials vertically up or down can save floor space and move goods between multiple floors of a building or production line to accommodate steep slopes or vertical lifting. Applications include moving goods in wishouses, manufacturing plants and distribution centers.

|

Type |

Picture |

Conveying angle range |

Applicable fertilizer type |

Typical application scenarios |

|

Horizontal belt conveyor |

|

0° ~ 10° |

Granular, powder, organic fertilizer |

Internal transportation of fertilizer workshop, wishouse transfer line |

|

Inclined belt conveyor |

|

10° ~ 45° (commonly 15° ~ 30°) |

Granular, organic fertilizer, wet material |

Fertilizer is lifted from the ground to the silo, mixing tank loading port |

|

Vertical belt conveyor |

|

45° ~ 90° |

Powder, granular, sticky fertilizer |

Fertilizer is transported vertically into high-level storage silos, feeding system |

Video of belt conveyor fertilizer

How does the belt conveyor fertilizer work?

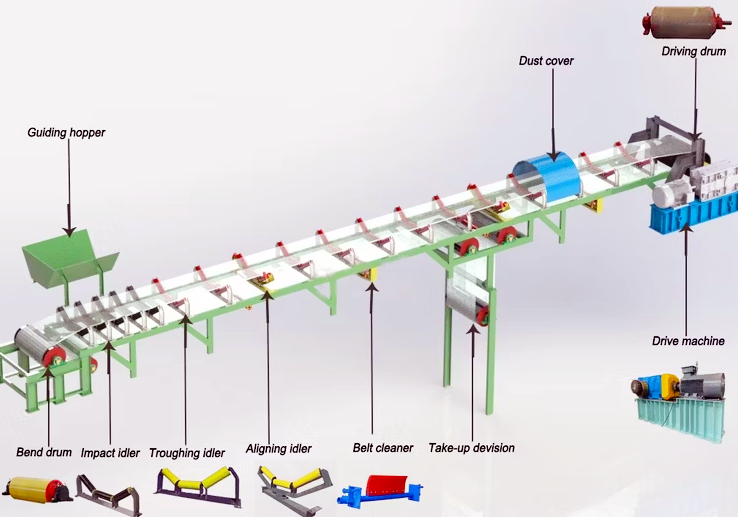

The fertilizer is placed at the starting point and fed into the feed port of the conveyor belt by the feeding device. The drive device drives the belt conveyor fertilizer to move and drive the fertilizer along the conveying direction. During the movement, the fertilizer is supported and guided by multiple rollers and drums. When it reaches the destination, it is discharged to the designated location through the discharge port.

Basic structure of belt conveyor fertilizer

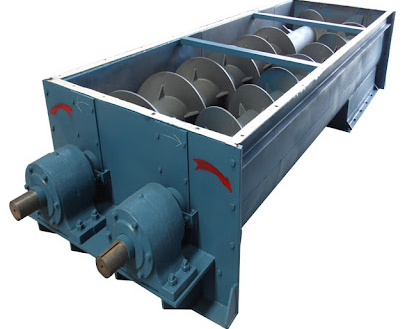

Conveyor belt body: The material is mostly rubber, PVC or PP. The appropriate material is selected according to the corrosiveness and water content of the fertilizer.

Drive device (motor): Provide power and control the running speed of the conveyor belt.

Roller system: Support the belt conveyor fertilizer, reduce friction, and maintain stable conveying.

Tensioning device: Maintain the tension of the conveyor belt to prevent slipping.

Unloading device (optional): Such as hopper and flap, used to control the unloading position of fertilizer.

Features of belt conveyor fertilizer

High conveying efficiency: It can continuously convey fertilizer, and the conveying speed can be adjusted according to needs, which greatly improves the handling and processing efficiency of fertilizer.

Large conveying capacity and high height: The conveying capacity of the belt conveyor fertilizer is very large, which can reach 6000t/h, and its conveying height is very high, which can reach 203m.

Wide application range: It can transport fertilizers in various forms, such as powder, granular, block, etc., and can also adapt to different working environments, such as indoor, outdoor, humid environment, etc.

Simple structure: It is mainly composed of basic components such as belt conveyor fertilizer, transmission device, bracket, etc. The structure is relatively simple, easy to install and maintain, and reduces the cost of equipment use.

High degree of automation: It can cooperate with other equipment to realize the automated fertilizer transportation and processing process, reduce manual intervention, and improve the automation level and management efficiency of production.

Application of belt conveyor fertilizer

Belt conveyor fertilizer is a mechanical equipment used in agriculture, fertilizer production or processing to efficiently and continuously transport fertilizers (such as granular fertilizers, powdered fertilizers, organic fertilizers, etc.) from one location to another. It is widely used in fertilizer production lines, farmland fertilization, wishousing and logistics, etc., and can significantly improve operating efficiency and automation level.

Fertilizer conveyor belts is used to transport raw materials such as minerals, organic matter or chemical components to processing or mixing isas. This may include phosphate rock, potassium salt, urea, ammonium nitrate and other ingredients used in fertilizer production. Finished fertilizer is conveyed from the production line to the packaging isa, where it is weighed, bagged and prepisd for distribution. Conveyor belts is used to efficiently move pallets or bulk fertilizer bags between storage isas, loading docks and trucks. They help streamline logistics and distribution processes.

Fertilizer production workshop: raw material transportation, finished product transfer.

Wishousing and logistics center: loading, stacking, unloading.

Agricultural field transfer: temporary transfer with packaging machines or feeding equipment.

Belt conveyor fertilizer usage and maintenance recommendations

To ensure efficient operation and extend the service life of fertilizer conveyor belts, regular maintenance is required:

Daily inspection: Check the conveyor belt for tears, wear, poor alignment or accumulated materials. Check the roller for damage or poor rotation.

Regular cleaning: Remove fertilizer and dust accumulated on the belt conveyor fertilizer and rollers to avoid corrosion of the conveyor belt material to prevent slipping and wear.

Roller lubrication: Lubricate the roller bearings regularly and keep the motor and rollers clean and lubricated to ensure smooth rotation.

Parts replacement: timely replace worn or damaged conveyor belts, rollers and other parts to avoid overload operation and prevent motor burnout.

Alignment correction: regularly check and adjust the alignment of the belt conveyor fertilizer to prevent deviation and uneven wear.