Bulk material conveyor

Bulk material conveyors utilize specialized load-bearing and traction components to efficiently transport various bulk materials from their origin to their destination.

Conveying distance: 10-100 meters

Conveying length: 12-102 meters

Conveying capacity: 50-1000 tons/hour

Applicable materials: Coal, ore, grain, sand and gravel

Material: Carbon steel Q235 / stainless steel 304

Bulk material conveyor is a mechanical device that continuously transports powdery, granular, or lumpy materials. It uses conveyor belts, screw conveyors, or bucket conveyors to transport materials from silos or hoppers to designated locations. It can adapt to the conveying needs of materials with different particle sizes and moisture content, and reduce the intensity of manual handling.

-

Bulk material conveyors typically have a conveying distance of 50 to 200 meters, and the angle of inclined conveying is generally no more than 20°. The hourly output can be designed according to the belt width and belt speed, with a common range of 500-3000 tons/hour. It can directly transport materials to silos at a specified height for storage, or flexibly load materials onto waiting trucks through devices such as loading chutes, to achieve continuous transfer operations.

Bulk materials vary in density, particle size distribution, moisture content, viscosity, flowability, and corrosivity. Therefore, the material, width, and length of a bulk material conveyor must be customized based on the specific characteristics of the material being screened. For damp, easily agglomerated materials, the conveyor can be equipped with anti-clogging devices; for abrasive ores, enhanced wear resistance is required. Regarding material selection, ordinary carbon steel is suitable for non-corrosive general-purpose materials; stainless steel is suitable for corrosion-resistant applications such as food and chemical processing; and special alloys are suitable for harsh environments with high temperatures and high abrasion.

What are the advantages of bulk material conveyors?

Bulk material conveyors can transport various bulk solid materials, from powders and granules to lumps, meeting the needs of continuous, high-volume logistics. The enclosed design effectively prevents dust escape and material contamination by moisture, making it particularly suitable for conveying easily dusty, toxic, or hazardous materials, or materials requiring cleanliness, while also reducing the impact of the external environment on the materials. Open conveyors, on the other hand, have a simpler structure, lower cost, and are easier to observe and maintain. They are typically used for conveying non-sensitive materials that do not easily generate dust or have larger, less dispersed particles. Enclosed design is key to achieving environmental protection and material protection, while open design offers advantages in cost and maintainability. Depending on whether the conveying path is straight, curved, or requires multiple loading and unloading points, there is a wide range of choices for bulk material conveyors, including belt conveyors, chain conveyors, and screw conveyors.

Bulk material conveyor types

Based on their working principles and structural characteristics, bulk material conveyors can be categorized into four common types to suit different application scenarios. Belt conveyors can adapt to various terrains, operating horizontally, inclined, or on curves, offering high conveying capacity, long conveying distances, and continuous operation. Screw conveyors can achieve horizontal, inclined, or vertical conveying, providing some mixing and crushing effects on materials, and enabling functions such as quantitative feeding, mixing, adding, or unloading. Tubular conveyors can achieve conveying at large angles, on curves, and along complex paths, replacing multiple traditional belt conveyor systems for long-distance sealed conveying, with a conveying capacity of 200–800 t/h. U-shaped conveyors can be equipped with covers for semi-enclosed or fully enclosed conveying, used for horizontal or slightly inclined conveying of powdery, granular, and small lump materials, with a conveying capacity of 5–150 t/h.

What are the specifications of bulk material conveyors?

| ST Rating | Recomm-ended Cord Dia (mm) | Pitch (mm) ±1.5 | Belt Width | Minimum Recommended Pulley Diameters (mm) for MAWT utilisation > 60% | |||||||||||||

| 800 | 900 | 1000 | 1050 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | A | B | C | |||

| 500 | 2.6 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 560 | 2.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 630 | 2.9 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 500 | 400 | 315 |

| 710 | 3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 800 | 3.1 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 630 | 500 | 400 |

| 900 | 3.3 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1000 | 3.5 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 197 | 800 | 630 | 500 |

| 1120 | 3.7 | 12 | 64 | 71 | 81 | 84 | 97 | 114 | 122 | 131 | 147 | 164 | 181 | 164 | 800 | 630 | 500 |

| 1250 | 4.2 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1400 | 4.5 | 14 | 55 | 61 | 69 | 72 | 84 | 98 | 104 | 112 | 127 | 141 | 155 | 169 | 800 | 630 | 500 |

| 1600 | 5 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 1800 | 5.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2000 | 6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2250 | 6.2 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1000 | 800 | 630 |

| 2500 | 6.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 2800 | 7 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3150 | 7.4 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1250 | 1000 | 800 |

| 3550 | 8 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4000 | 8.6 | 15 | 50 | 57 | 64 | 67 | 77 | 90 | 97 | 104 | 117 | 130 | 144 | 157 | 1400 | 1250 | 1000 |

| 4500 | 9.2 | 16 | 46 | 52 | 59 | 65 | 71 | 84 | 90 | 96 | 109 | 121 | 134 | 146 | 1400 | 1250 | 1000 |

| 5000 | 10.4 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 5400 | 11 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 1600 | 1250 | 1000 |

| 6300 | 11.6 | 17 | 43 | 48 | 55 | 60 | 66 | 78 | 84 | 90 | 102 | 113 | 125 | 137 | 2000 | 1800 | 1600 |

How does a bulk material conveyor work?

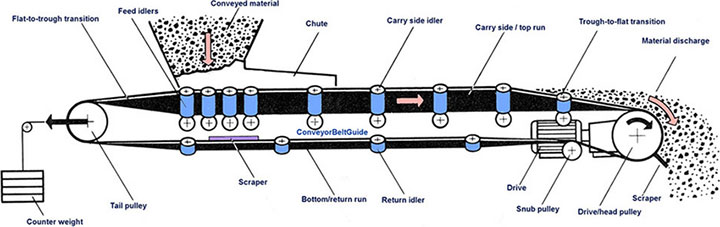

A bulk material conveyor operates as follows: a drive unit rotates the drive roller, pulling the conveyor belt in a continuous loop through friction. Material evenly falls from the loading point at the rear of the conveyor onto the conveyor belt, moving along with it to the unloading point at the front of the conveyor. The material is unloaded by the unloading device, and then the empty conveyor belt is supported by the lower return rollers and returns to the loading point, repeating the cycle.

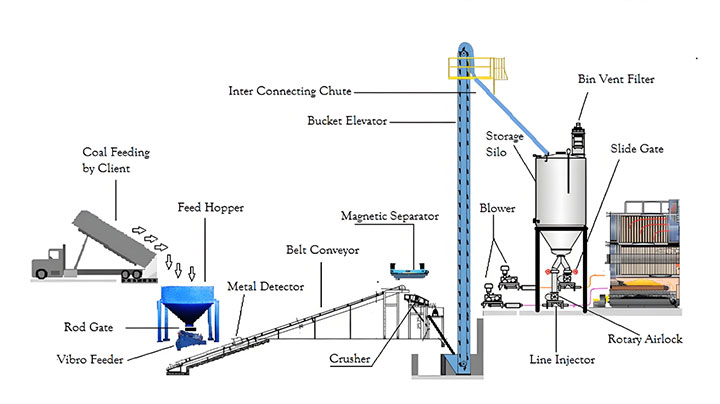

Bulk Material Conveyor System Display

How much does a bulk material conveyor cost?

Conventional bulk material conveyors have conveying lengths of 10-30 meters and conveying capacities of 50-200 cubic meters per hour, costing approximately $8,000-15,000. Large scraper conveyors or bucket elevators, suitable for mines and large factories, have conveying capacities exceeding 200 cubic meters per hour and are more expensive, typically ranging from $20,000-50,000. Custom designs, the use of specialized materials (such as stainless steel or wear-resistant alloys), or the addition of automated control systems can increase the price depending on specific needs.

What are the components of a bulk material conveyor?

Taking the most common belt conveyor as an example, the core structure of a bulk material conveyor consists of the following basic components: a conveyor belt, serving as the traction and load-bearing member; a drive unit, typically consisting of a motor, a speed reducer, and a drive roller, providing system power; a tensioning device, maintaining sufficient belt tension; an idler assembly, including load-bearing sections and return rollers, supporting the conveyor belt and the material; and a frame, the overall supporting structure, all of which together enable continuous conveying of bulk materials.

Bulk Material Conveyor Manufacturer

Dahan Machinery's Bulk Material Conveyor systems utilize advanced manufacturing processes and can be configured with hydraulic structures or double-helix designs according to customer needs. Quality standards are strictly controlled throughout the manufacturing process, ensuring optimal operation during use and creating higher production efficiency and economic benefits for customers.

Bulk Material Conveyor Customer Case

To address the severe dust pollution, high energy consumption, and frequent malfunctions in its aging production lines, a cement group introduced a fully enclosed tubular belt conveyor system at its limestone pre-homogenization stockpile. This project enabled the transport of raw materials from the port to the plant area over several kilometers, eliminating material spillage and dust, and reducing energy consumption by over 15%. At the dedicated grain terminal, an integrated conveying solution was used, including chain elevators, large-capacity buried scraper conveyors, and multiple trestle belt conveyors. This system automates the entire process of bulk grain unloading from ship holds, conveying it through corridors, and storing it in silos. Its lightweight design ensures the integrity of grain particles, and conveying efficiency is improved by over 30%.