Wheat spring suction conveyor

The Wheat Spring Suction Conveyor is suitable for grain processing (flour, starch), storage, and feed production.

Conveying Capacity: 60-100 tons/hour

Conveying Pipe Diameter: Φ100-150 mm

Conveying Speed: 18-28 m/s

Pipe Material: Carbon Steel/Stainless Steel

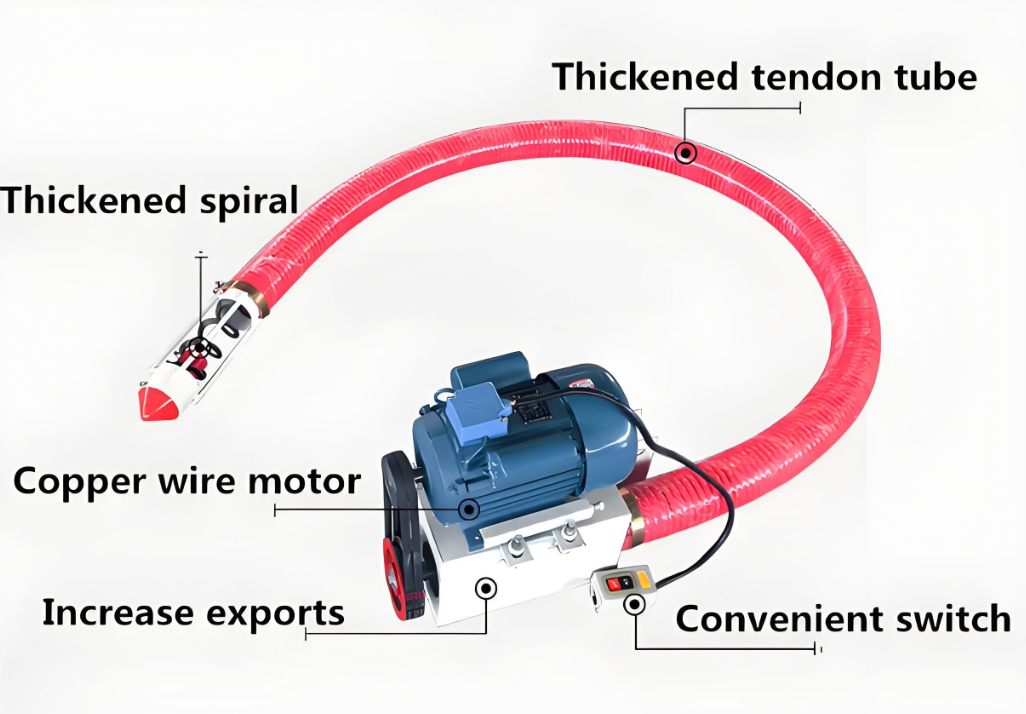

Wheat spring suction conveyor

The Wheat spring suction conveyor flexibly connects storage, cleaning, and processing, avoiding the problems of grain breakage and dust pollution associated with traditional conveying. It also adapts to the slightly higher moisture content of wheat, reducing material blockage. Its compact size makes it easy to deploy in field storage locations or small processing plants, significantly improving wheat transfer efficiency and reducing labor costs.

What is a Wheat Spring Suction Conveyor?

Wheat is a major global grain crop characterized by its hygroscopicity, high hardness, good flowability, and uniform particle size. During the wheat harvest, conveying equipment is often required to transport the wheat, reducing manual labor. The Wheat Spring Suction Conveyor is a commonly used conveying device.

The conveying capacity of a wheat spring suction conveyor typically ranges from 2 to 20 tons per hour. For example, a 100mm diameter machine can convey 5 to 6 tons per hour, and a 120mm diameter machine can convey 7 to 8 tons per hour. Its horizontal conveying distance is generally 3 to 15 meters, and its vertical conveying height is 1.5 to 4 meters. The price ranges from US$200 to US$1,000 per unit, depending on the machine's specifications and functionality.

How does a wheat spring suction conveyor work?

The wheat spring suction conveyor utilizes the principle of negative pressure pneumatic conveying. When the fan operates, it creates a high-speed airflow and negative pressure within the pipe, drawing the wheat into the conveyor nozzle. The material and air mix to form a two-phase flow, which is then conveyed through the conveying pipe to a separation device. In the separation device, the material is separated from the air by gravity and centrifugal force. The air is discharged after dust removal, and the material is discharged stably through an air lock, completing the conveying process.

Wheat Spring Suction Conveyor Technical Specifications

| Tube diameter | length | Voltage | Power | Effectiveness | Weight |

| 100mm | 3 m | 220V | 3KW | 5-6 t | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6t | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6t | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6t | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6t | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6t | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6t | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6t | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6t | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6t | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8t | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8t | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8t | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8t | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8t | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8t | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8t | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8t | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8t | 89kg |

| 120mm | 12m | 380V | 4KW | 7-8t | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6t | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6t | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7t | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7t | 200kg |

How can a wheat spring suction conveyor be used?

Wheat spring suction conveyors are categorized by their mobility, with two common types: fixed and mobile.

Fixed Wheat Spring Suction Conveyor Installation: The conveyor is fixed to a specific location, such as a silo inlet or a processing workshop feed point. The piping system is fixed to form a stable conveying route. This type of conveyor is suitable for large grain warehouses, grain processing plants, feed mills, and other applications requiring continuous, high-volume delivery along a fixed path.

Mobile Wheat Spring Suction Conveyor Operation: The entire conveyor (including the main unit, motor, suction nozzle, and hose) is mounted on a wheeled mobile frame and can be flexibly towed to various locations. It is particularly suitable for: unloading grain from bulk trucks to convey wheat directly to silos; transferring grain between silos; unloading grain from small vessels at docks; and collecting scattered grain on the ground during site cleanup.

Wheat spring suction conveyors can be divided into three types based on their usage: common, handheld, and truck-type. The following are examples of these three types:

How much does a wheat spring suction conveyor cost?

Wheat spring suction conveyors generally cost between $200 and $2,000. For example, small household models are lightweight and easy to install, suitable for small household wheat transfers. They can quickly handle tasks like grain storage in grain silos, drying grain in gardens, and harvesting. They typically cost between $200 and $300. Standard commercial models are suitable for small and medium-sized farms and grain stations. They offer strong grain suction capacity, can operate continuously, reduce manpower, and can adjust the angle to suit different locations. They typically cost between $200 and $800. Large, high-performance, or customized models are designed for large-scale grain companies, offering higher conveying efficiency. Some models can be customized for conveying lengths and equipped with intelligent speed control systems. These models often cost over $1,000 and are suitable for high-volume, high-yield wheat transfers.

What are the benefits of using a wheat spring suction conveyor?

The Wheat Spring Suction Conveyor is ideal for wheat storage and processing. First, negative pressure suction enables continuous conveying, reducing manual intervention, labor intensity, and costs, making it suitable for large-scale production. Second, the spring structure cushions airflow, reducing wheat breakage and mold, while the sealed pipeline reduces material residue and ensures quality. Third, the pipeline layout is flexible, allowing it to climb slopes and turn, and some models are mobile, making them suitable for complex sites. Fourth, closed conveying reduces dust leakage, and the food-grade material is easy to clean, meeting hygiene requirements. Fifth, the durable spring assembly and the small number of core components simplify maintenance and reduce costs, improving overall conveying efficiency and safety.

Wheat Spring Suction Conveyor Usage Scenarios