Yellow corn spring suction conveyor

The Yellow Corn Spring Suction Conveyor is a flexible continuous conveying device designed for conveying dry bulk granular materials (such as yellow corn).

Capacity: 5-20 tons/hour

Conveying Distance: ≤15 meters

Power: 3-7.5kW

Applicable Materials: Yellow corn and other granular materials

Features: No residue, anti-clogging, and easy to clean.

Yellow-corn-spring-suction-conveyorare available in three main types: horizontal conveyor, vertical lift, and inclined conveyor. Their core principle is to use a rotating spring to propel material within a closed pipe, achieving dust-free conveying.

What is a Yellow Corn Spring Suction Conveyor?

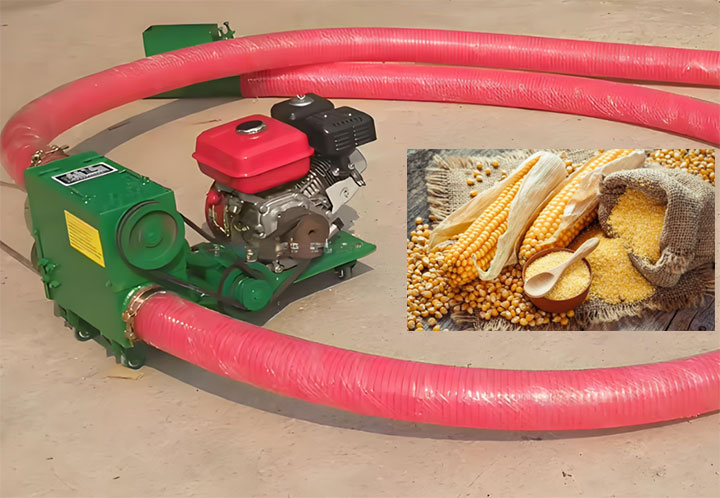

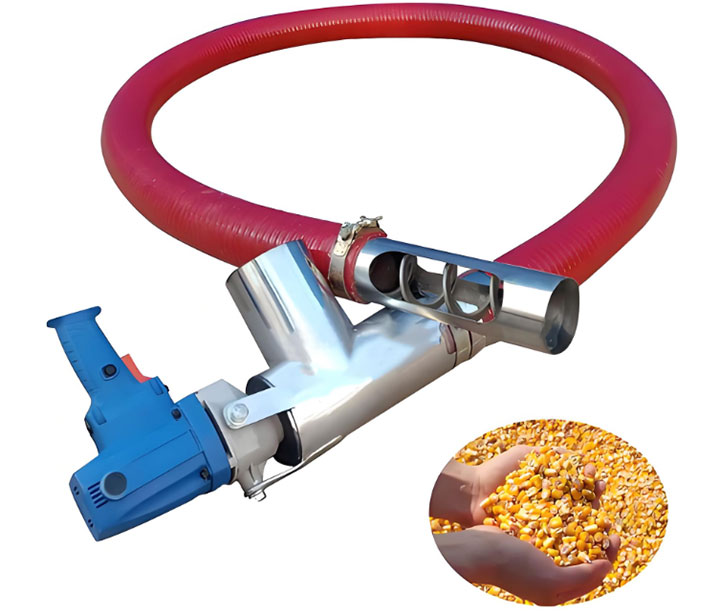

The Yellow Corn Spring Suction Conveyor conveys dry corn. The device can be handheld or used with a truck for easy transport.

The standard conveying capacity of a single Yellow Corn Spring Suction Conveyor is typically between 10 and 60 tons/hour. The optimal conveying distance is generally within 15 meters horizontally or within 5 meters vertically. For distances exceeding these limits, multiple units can be connected in series. The main parts of the equipment that come into contact with the material are constructed from food-grade 304 or 316 stainless steel, ensuring cleanliness, rust resistance, and wear resistance. Depending on the configuration, material, and size, the market price of a standard unit ranges from $5,000 to $15,000 USD.

Yellow Corn Spring Suction Conveyor Technical Specifications

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5meter | |||||||

| 6meter | |||||||

| 8meter | |||||||

| (Customized) | |||||||

What are the types of Yellow Corn Spring Suction Conveyors?

Main Types of Yellow Corn Spring Suction Conveyors: Depending on the specific application requirements, this equipment can be derived from several common types. The most common type is the fixed type, which is permanently installed at a specific workstation using a bracket. It offers high stability and is a workhorse on the production line. The second most common type is the mobile type, which integrates the entire conveyor system (including the drive unit and suction hose) onto a mobile bracket with wheels. This offers extreme flexibility and can be used for suction operations at multiple different openings, making it particularly suitable for warehousing and unloading applications. Furthermore, depending on the conveying path, it can be categorized as a basic horizontal type or an inclined lift type. The latter requires greater motor power to overcome gravity.

Advantages of Yellow Corn Spring Suction Conveyors for Conveying Yellow Corn

Compared to traditional conveying machinery, Yellow Corn Spring Suction Conveyors offer exceptional flexibility. Their core conveying components utilize flexible springs, allowing the conveying pipe to bend within a certain range. This allows them to effectively navigate around obstacles and address conveying challenges in complex environments.

The entire conveying process occurs within a sealed pipe, effectively preventing dust leakage, protecting the work environment while also avoiding material loss and cross-contamination. Yellow Corn Spring Suction Conveyors are highly modular, requiring no complex foundation work for installation; they require only simple support and mounting for immediate operation. The springs, considered consumable parts, are designed for quick removal and replacement, significantly reducing ongoing maintenance costs and time.

Yellow Corn Spring Suction Conveyors are typically equipped with moving wheels and adjustable suction arms, allowing for flexible adaptation to various work sites and vehicles, enabling rapid deployment and operation. Their "spring" or "flexible spiral" structure gently breaks up material clumps, ensuring smooth conveying and reducing blockages. Furthermore, this relatively gentle conveying method minimizes damage to the yellow corn kernels, helping to maintain the integrity and quality of the material.

Yellow corn spring suction conveyor purchase

The price of a yellow corn spring suction conveyor varies significantly depending on the model, power, conveying capacity, and material. Small portable units start at approximately $800-$1,500. Mid-sized commercial models typically cost between $2,000-$5,000. Large industrial, high-capacity, and all-stainless steel models can cost between $7,000-$12,000.

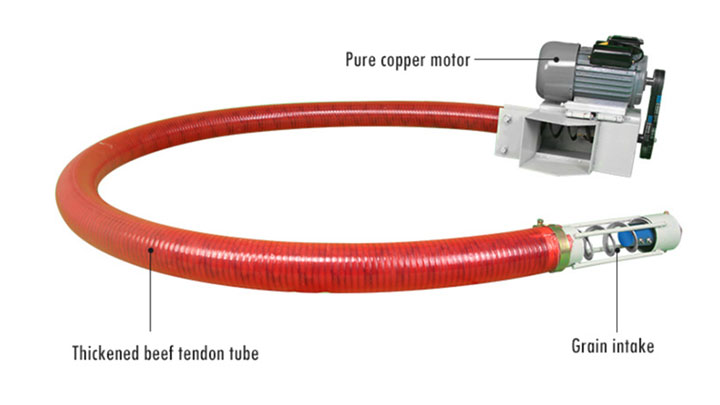

Yellow corn spring suction conveyor structure

The yellow corn spring suction conveyor structure consists of three main components: the conveying pipe is a seamless stainless steel pipe with a smooth inner wall to reduce residue, and its diameter directly affects conveying capacity. The coil spring is made of high-strength stainless steel for wear and torsion resistance, and its ends are welded with a wear-resistant alloy. When rotating at high speed, it generates suction and propels the material. The drive unit, consisting of a motor, reducer, and sealed gearbox, provides stable speed and torque, ensuring reliable operation.

Applications of Yellow Corn Spring Suction Conveyors

Yellow corn spring suction conveyors are widely used in various industrial and agricultural applications where yellow corn is used as a raw material. Their primary application is in grain storage and transshipment, where they are used to quickly unload bulk corn from trucks and pits and transport it to the warehouse's elevator entrance. Secondly, in feed processing plants, they are responsible for precisely transporting raw corn from the warehouse to the grinder, mixer, or pelletizer for front-end processing. Yellow corn spring suction conveyors are also used in corn processing plants, such as those producing corn starch, alcohol, and glucose, as well as in the raw material pre-processing workshops of breweries. Even grain transfer stations at ports and terminals employ large-scale models of these devices for short-distance material distribution and transportation.