Bulk Material Hose Screw Conveyor

Thursday December-18 2025 13:24:52

Bulk Material Hose Screw Conveyor uses a flexible hose and an internal spiral rotation to transport bulk materials from the inlet of the conveyor pipe to the desired location.

The hose inner diameters of the Bulk Material Hose Screw Conveyor are available in Φ40, Φ50, Φ63, Φ75, Φ90, Φ100, Φ125, and Φ150 mm, which can be selected according to the size of the material. Conveying distances range from 2 to 17 meters. If the conveying distance is insufficient, connecting pipes can be installed to connect different hoses to achieve the required length. The equipment can convey horizontally, inclined, or vertically, and can be powered by electric, gasoline, or diesel engines. It can also be mounted on a frame or truck, depending on the application. The conveying capacity is typically 0.5-40 m³/h.

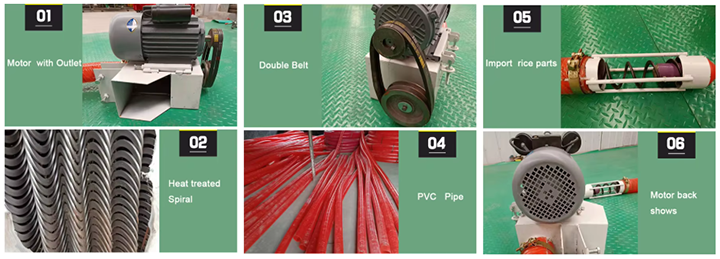

Bulk Material Hose Screw Conveyor Design

The drive unit of the Bulk Material Hose Screw Conveyor is usually installed at the inlet end of the conveyor. Depending on the operating conditions, an electric motor, gasoline engine, or diesel engine can be selected as the drive unit. The auger inside the conveying pipe acts like a large spring, typically made of high-strength spring steel, or using special wear-resistant and corrosion-resistant steel or coatings. A drive unit provides power to rotate the auger, continuously propelling the material forward along the pipe. The inner diameter of the conveying hose is slightly larger than the outer diameter of the auger, providing space for auger rotation and material flow. The inlet can be funnel-shaped, flanged, or a hose connection for easy connection to upstream equipment. For complex paths, a fixed steering knuckle is used to connect two hose sections, allowing for large-angle or directional turns, which sacrifices some continuity.

Advantages of the Bulk Material Hose Screw Conveyor

The Bulk Material Hose Screw Conveyor's hose is flexible and can be placed in complex working conditions, offering greater flexibility compared to rigid conveyors. The pipe is sealed, preventing material spillage during transport. The equipment is highly flexible, allowing for horizontal, inclined, or vertical conveying, and can be used in a bracket-mounted or truck-mounted configuration. The overall weight is less than a rigid screw conveyor, requiring only one person to move it. The material, length, and diameter of the pipes can be customized, making them suitable for a wide range of applications.

Bulk Material Hose Screw Conveyor Parameters

| Hose Inner Diameter (mm) | Approximate Screw Diameter (mm) | Typical Speed Range (RPM) | Estimated Volume Conveying Capacity (m³/h) | Mass Conveying Capacity (t/h) (Based on Bulk Density 0.8 t/m³) |

| Φ63 | Φ50 | 150 - 300 | 0.5 - 2.0 | 0.4 - 1.6 |

| Φ90 | Φ75 | 120 - 250 | 1.5 - 5.0 | 1.2 - 4.0 |

| Φ125 | Φ100 | 100 - 200 | 4.0 - 12.0 | 3.2 - 9.6 |

| Φ150 | Φ125 | 80 - 180 | 8.0 - 20.0 | 6.4 - 16.0 |

| Φ200 | Φ160 | 60 - 150 | 15.0 - 40.0 | 12.0 - 32.0 |

Bulk Material Hose Screw Conveyor Types

Bulk Material Hose Screw Conveyors can be categorized by power source and installation method. Users can choose the appropriate power source and installation method based on the available space, power supply, movement frequency, and material characteristics at the work site to achieve loading, unloading, and conveying.

Bulk Material Hose Screw Conveyors can also be categorized by power source into electric, gasoline, and diesel models. Electric models are suitable for scenarios with a stable power supply. Gasoline models are suitable for outdoor mobile or small-to-medium-sized decentralized operations, offering strong power. Diesel models are suitable for heavy-duty, continuous, and long-term outdoor operations; they are heavier but more durable.

Bulk Material Hose Screw Conveyors can be categorized by installation method into bracket-mounted and fixed models. Bracket-mounted models are equipped with brackets or wheels for easy movement or positioning. Fixed models can be installed on trucks or trailers to form a complete mobile conveying unit, allowing for rapid relocation.

Bulk Material Hose Screw Conveyor for Sale

For small agricultural machines, with a length of approximately 1-3 meters, the price ranges from $260 to $800. For standard models, with a pipe length of 1-5 meters, the price ranges from $1,000 to $3,300 USD per set. The price depends on factors such as pipe length, diameter, material, drive system, and custom design. Many factors influence the machine's price; providing the manufacturer with information such as material characteristics, conveying requirements, and working environment will result in a detailed quote.

Bulk Material Hose Screw Conveyor Price List

| Hose Diameter (mm) | Length (m) | Motor Power (kW) | Estimated Price Range (USD) | Notes |

| 100 (4") | 3 - 5 | 1.5 - 2.2 | $1,000 - $2,000 | Small-sized, short-distance conveying |

| 150 (6") | 5 - 10 | 2.2 - 4.0 | $2,100 - $3,500 | Most common medium size |

| 200 (8") | 8 - 15 | 4.0 - 7.5 | $3,700 - $5,500 | Medium conveying volume, wide applicability |

| 250 (10") | 10 - 18 | 7.5 - 11 | $6,000 - $9,000 | For larger conveying volume needs |

| 300 (12") | 12 - 20 | 11 - 15 | $10,000 - $15,000 | Large-sized, high-conveying-volume configuration |

Bulk Material Hose Screw Conveyor Manufacturers

Bulk Material Hose Screw Conveyor manufacturers are located worldwide, including in Germany, the United States, Italy, China, and India. Equipment manufactured in Germany, the United States, and Italy is durable and sophisticatedly designed, but is correspondingly more expensive and has longer delivery times. Chinese manufacturers, such as Dahan Machinery, offer both standard and customized models, with CE-certified technology, fast service response, and lower prices. Indian manufacturers are suitable for simpler operating conditions, capable of fulfilling basic conveying needs, and their prices are generally lower than those in China.

Bulk Material Hose Screw Conveyors can be used in grain mills, fields, construction sites, and other environments to convey various types of materials, including wheat, corn, soybeans, rice, feed, grains, tea, coffee beans, gypsum powder, dry sand, mortar powder, fertilizer, and resin granules.