Chemical raw material screw conveyor

Friday March-21 2025 15:22:53

Chemical raw material screw conveyor is a kind of mechanical equipment specially used for conveying chemical raw materials. It usually pushes the materials from one end to the other end by rotating spiral blades. It is widely used in chemical, metallurgical, building materials, food and other industries. It is suitable for chemical raw materials in various forms such as powder, granular, small block materials, etc.

Video of chemical raw material screw conveyor

Applicable materials of chemical raw material screw conveyor

①Powdered materials: such as alumina powder, sulfate, calcium carbonate, plastic powder.

②Granular materials: such as fertilizer granules, catalyst granules, resin granules.

③Special materials: some corrosive raw materials (such as acid powder) or high temperature materials (high temperature resistant design is required).

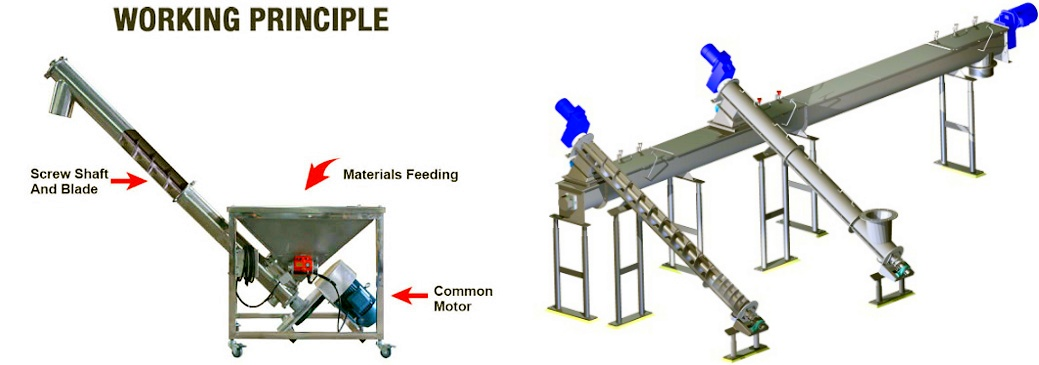

What is the working principle of the chemical raw material screw conveyor?

Chemical raw material screw conveyor drives the chemical raw materials to move axially through the rotating spiral blades to achieve transportation.

Core components: spiral shaft (with spiral blades), material trough, and drive device.

Movement process: The drive device drives the spiral shaft to rotate, and the spiral blades rotate in the casing, pushing the chemical raw materials forward along the spiral trough and finally discharged from the discharge port.

What are the advantages of chemical raw material screw conveyors?

1. Special screw design: Chemical raw material screw conveyors can be designed with screws of different shapes and spacings according to the characteristics of different raw materials to improve conveying efficiency and prevent raw materials from agglomerating.

2. Surface coating treatment: The surface of the chemical raw material screw conveyor is specially coated to reduce the adhesion of raw materials during transportation and reduce the possibility of agglomeration and blockage.

3. Heating or cooling device: Heating or cooling the conveying pipeline to adjust the temperature of the raw materials to avoid adhesion or agglomeration of sticky raw materials during transportation.

4. Anti-blocking design: The chemical raw material screw conveyor is equipped with anti-blocking devices in the conveying pipeline, such as anti-blocking plates, anti-blocking baffles, etc., to prevent raw materials from being blocked during transportation.

Recommended mesh count for chemical raw material screw conveyors

|

Chemical raw material types |

particle size range |

recommended mesh count range |

applicable screw conveyor types |

|

Powdered materials |

0.01–0.15mm |

100–1200 mesh |

shafted screw conveyors |

|

Fine particles |

0.15–2mm |

10–100 mesh |

shafted or shaftless screw conveyors |

|

Medium particles |

2–5mm |

4–10 mesh |

shafted screw conveyors |

|

Viscous materials |

0.05–5mm |

10–300 mesh |

shaftless screw conveyors |

|

Corrosive materials |

0.01–1mm |

20–1200 mesh |

stainless steel shafted screw conveyors |

Application of chemical raw material screw conveyor

The application of chemical raw material screw conveyor covers multiple links from raw material storage to processing and finished product packaging. Specific scenarios include:

Short-distance transportation within the workshop: such as material transfer from the reactor to the mixer.

Production line connection: such as continuous transportation from screening equipment to packaging machines.

Cross-floor transportation: such as vertical lifting from the ground to the high-rise warehouse.

Special environment treatment: such as customized requirements for high temperature, corrosion or clean workshops.

In chemical production, screw conveyors can play the role of conveying, mixing, and feeding, helping chemical companies to realize the automated transportation and processing of raw materials, improve production efficiency, reduce labor costs, and ensure the continuity and stability of the production process.