Flexible Screw Conveyor For Carbon Black

Saturday December-06 2025 13:40:33

Flexible Screw Conveyor For Carbon Black uses a rotating helical spring inside a flexible hose to transport powdered, granular, and ultrafine carbon black to a designated location. The hoses used for conveying carbon black are made of materials such as PU polyurethane hoses, PVC transparent hoses, and food-grade TPU hoses. The helical springs are made of high-strength, wear-resistant carbon steel or stainless steel, and their surfaces can be hardened or specially coated to extend their service life.

The conveying capacity of the Flexible Screw Conveyor for Carbon Black ranges from 1 to 20 m³/h, depending on the density and particle size of the carbon black. The conveying length is approximately 2–40 m, and the rotational speed ranges from 200 to 900 rpm, adjustable according to the carbon black particle size to reduce dust and wear. The motor models are primarily compact, well-sealed geared motors, with explosion-proof ratings available upon request. Motor power ranges from 1.1 to 7.5 kW. Common models include hose diameters of Φ114, Φ159, Φ219, and Φ273.

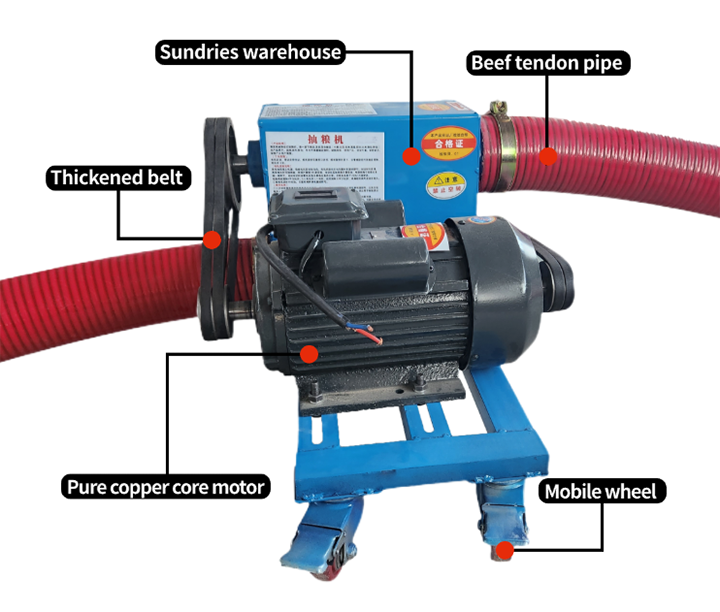

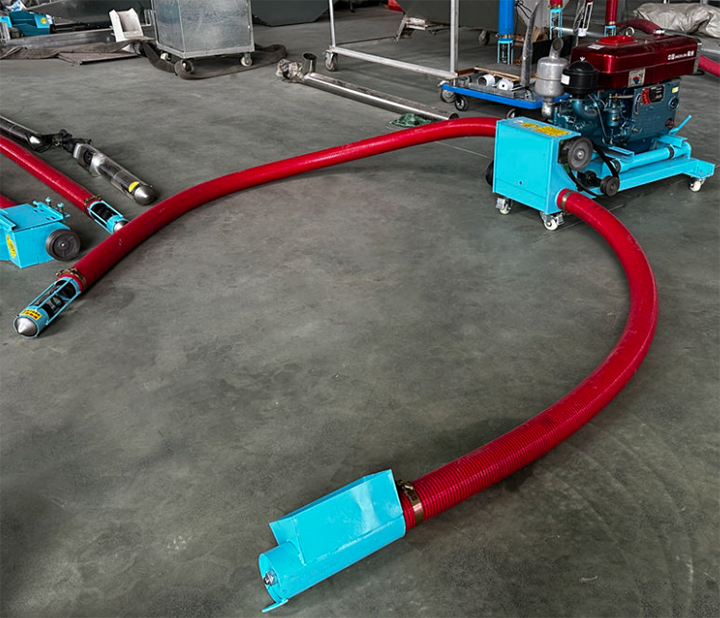

Flexible Screw Conveyor for Carbon Black Components

The Flexible Screw Conveyor for Carbon Black includes a motor, inlet and outlet ports, hoses, and a flexible screw conveyor. The motor, reducer, and sealed transmission box are the core power source. The inlet port is typically equipped with an interface for connecting to a silo or storage tank, while the outlet port discharges carbon black into mixers, packaging machines, etc., and can be equipped with a rotary valve or gate. The flexible conveying screw pushes the material, and the conveying hose forms the conveying channel. The control system includes a frequency converter, start/stop switches, and interlocking protection devices.

Features of the Flexible Screw Conveyor for Carbon Black

The Flexible Screw Conveyor for Carbon Black can handle fine carbon black with a particle size ranging from 10–100 nm. This type of carbon black is prone to dust generation; the flexible screw conveyor's good sealing prevents dust leakage and can also convey granular carbon black. The equipment has a small gap between the conveying screw and the pipe wall, but due to the flexibility of the pipe and the continuous rotation of the screw, carbon black is easily conveyed without clogging. Carbon black has a low apparent density, allowing for uniform feeding through adjustable rotation speed. Its flexible design makes it suitable for confined spaces, offering strong adaptability to existing production line modifications and reducing equipment footprint. Carbon black powder has a certain degree of abrasiveness; therefore, the equipment can be equipped with wear-resistant spiral blades and wear-resistant tubing to extend its service life.

Flexible Screw Conveyor for Carbon Black Models

When selecting a Flexible Screw Conveyor for Carbon Black, the required pipe diameter varies depending on the particle size range of the carbon black. Using a smaller model for too large a carbon black particle size can cause pipe blockage, while using an excessively large model for too small a particle size will reduce the conveying capacity. The following models are for reference:

For ultrafine carbon black (particle size < 1μm), the LS-100 model can be selected, with a conveying pipe diameter of approximately 100mm. This type of material is easily dispersed and has a low density. A smaller pipe diameter helps maintain a high material filling rate and stable conveying flow, preventing slippage or backflow in the pipe. The spiral blades should be continuous with a low to medium speed to reduce dust generation.

For fine-particle carbon black (1μm - 20μm), a general-purpose model with a medium pipe diameter, such as LS-150, is recommended. The conveying pipe diameter should be approximately 150mm; a medium diameter strikes a balance between conveying capacity and anti-clogging. Ensure an appropriate gap between the spiral and the pipe wall, typically ≤5mm, to prevent fine powder from getting stuck. Thickened or wear-resistant spiral blades are recommended.

For coarse-particle carbon black (> 20μm), a model with a larger pipe diameter, such as LS-200 or LS-250, is recommended. The conveying pipe diameter should be 200mm - 250mm. A larger flow cross-section reduces interference between particles and the risk of breakage. For granular carbon black, the spiral speed should not be too high; a larger pitch should be used to ensure gentle conveying.

Flexible Screw Conveyor for Carbon Black Parameter Table

| Model | Hose Inner Diameter (mm) | Screw Body Diameter (mm) | Recommended Max Length (m) | Recommended Max Conveying Capacity (m³/h)* | Motor Power Range (kW) |

|---|---|---|---|---|---|

| LS-100 | 114 | 100 | 8-10 | 2-4 | 1.1 - 2.2 |

| LS-125 | 140 | 125 | 10-12 | 4-8 | 2.2 - 4.0 |

| LS-150 | 168 | 150 | 12-15 | 8-12 | 3.0 - 5.5 |

| LS-200 | 219 | 200 | 15-18 | 12-20 | 5.5 - 11.0 |

| LS-250 | 273 | 250 | 18-20 | 20-30 | 7.5 - 15.0 |

Flexible Screw Conveyor for Carbon Black Case Study

A rubber products company encountered problems with its existing pneumatic conveying system for carbon black powder, including dust pollution, pipe blockage, and high energy consumption. To improve production efficiency, the company introduced the Flexible Screw Conveyor for Carbon Black as a replacement. The equipment is installed between the warehouse and the mixing mill, uniformly conveying carbon black to the mill through a suction inlet. It is also equipped with a sealed design and dust cover to reduce dust leakage. After implementation, conveying efficiency increased by approximately 30%, operating noise decreased by 20%, and maintenance costs were reduced.

The Flexible Screw Conveyor for Carbon Black can convey different types of carbon black materials, including powdered carbon black, fine granular carbon black, small agglomerated carbon black, and microbeaded carbon black. The price ranges from approximately $1200 to $8000, depending on the length, material, and additional features. Suppliers are located in countries such as the United States, Italy, and China. Among them, Dahan Machinery's production equipment is competitively priced and can provide services ranging from standard products to customized system solutions.