Flexible Screw Conveyor For Coffee Beans

Thursday December-04 2025 16:06:51

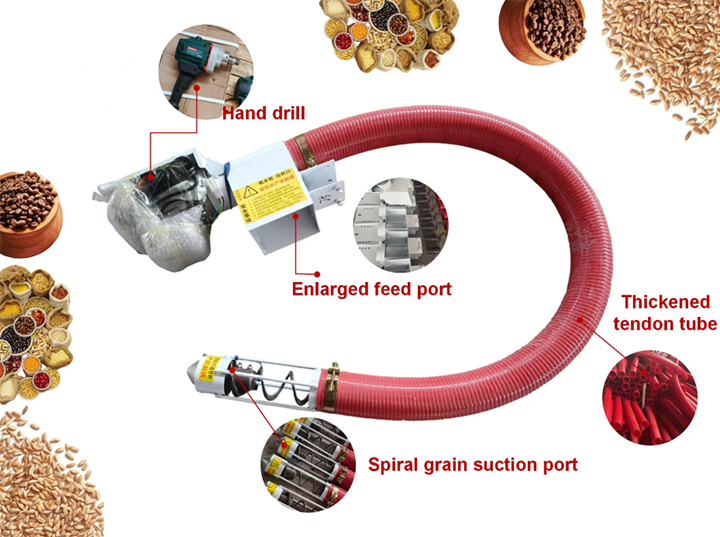

Flexible Screw Conveyor For Coffee Beans uses a rotating helical spring within a flexible plastic tube to transport green and roasted coffee beans from one enclosed area to another. The helical spring and conveyor hose, which come into contact with the coffee beans, are made of food-grade stainless steel, food-grade polyurethane, or polyethylene, ensuring hygiene and minimizing friction damage to the beans during transport.

The conveying capacity of the Flexible Screw Conveyor for Coffee Beans ranges from 1 to 50 cubic meters per hour, depending on the model selected. The speed can be adjusted according to the characteristics of the coffee beans and the production line cycle, typically between 60 and 300 rpm. Horizontal conveying distances range from 3 to 30 meters, and vertical conveying distances generally do not exceed 10 to 12 meters. Common tube diameters range from Ø38 to Ø114 mm, selectable based on production capacity. The hose helix allows for some bending and adjustment, but conveying efficiency decreases if the tilt angle exceeds 60°–65°.

Advantages of the Flexible Screw Conveyor for Coffee Beans

The closed-loop conveyor system of the Flexible Screw Conveyor for Coffee Beans prevents coffee beans or grounds from becoming damp, absorbing odors, or being contaminated by the environment during transport, which is crucial for maintaining the pure flavor of coffee. Its flexible conduit can bypass obstacles, enabling multi-angle and multi-directional transport, simplifying factory layout design and making it suitable for upgrading older factories or production lines with limited space. Compared to the frictional heat that can occur with pneumatic conveying or the impact of mechanical elevators, the smooth pushing of the screw conveyor causes less damage to coffee beans, especially brittle roasted beans, helping to reduce breakage and preserve the flavor of whole beans. This equipment can be connected to upstream roasters and cooling trays, and downstream grinders and packaging machines, enabling continuous and automated material flow from post-roasting to pre-packaging, improving overall production efficiency and reducing contamination and labor intensity caused by manual handling.

Different Models of the Flexible Screw Conveyor for Coffee Beans

Four different models of the Flexible Screw Conveyor are available to cater to different processing stages and material characteristics in the coffee industry. Small, medium, large, and anti-static models are available. Below is a detailed description of each model.

Small Model Flexible Screw Conveyor for Coffee Beans: Hose inner diameter 38mm, 45mm, 57mm. Suitable for specialty coffee roasting rooms and small packaging lines, where lower capacity but gentle conveying is required. Conveying capacity approximately 0.2–1 m³/h, conveying distance up to 5 meters, motor power 0.25–0.75 kW. Compact size, low noise, and easy to clean.

Medium Model Flexible Screw Conveyor for Coffee Beans: Hose inner diameter 75mm. Suitable for medium to large-sized roasting plants, meeting stable conveying needs of 2–4 m³/h, conveying distance up to 10 meters, motor power 1.5–3 kW. Suitable for centralized feeding systems at the front end of packaging lines, transfer in green bean pre-processing stages, and conveying beans before/after cooling after roasting.

Large-sized Flexible Screw Conveyor for Coffee Beans: Hose inner diameters of 90mm, 102mm, and 114mm. Suitable for industrial coffee processing plants for large-volume green bean conveying or high-capacity packaging. Conveying capacity reaches 4–12 m³/h, with a maximum conveying distance of approximately 20 meters. Motor power ranges from 4–7.5 kW. The large-sized model requires a high-power motor and shock-absorbing structure due to its high force and long distance, making it suitable for large-volume green bean storage and outbound transport.

Anti-static Flexible Screw Conveyor for Coffee Beans: Designed for coffee beans with high oil content and prone to static electricity. Available in food-grade or anti-static hoses. Features a special inner wall material and excellent sealing. Conveying capacity varies from 0.2–12 m³/h depending on the model. This model balances high hygiene standards with dust prevention, suitable for conveying dark roast coffee beans with high oil content.

Flexible Screw Conveyor for Coffee Beans Technical Specifications

| Item | Description |

|---|---|

| Conveying Capacity | 0.5-5 tons/hour |

| Pipe Diameter (Inner Diameter) | ∅38 mm, ∅55 mm, ∅75 mm, ∅90 mm, ∅114 mm |

| Conveying Distance | Horizontal: 5-40 m; Vertical: 2-12 m |

| Motor Power | 0.75-7.5 kW |

| Hose Material | Food-grade PU, PE, PVC, TPU |

| Screw Material | Stainless steel (304/316), carbon steel spring, food-grade alloy |

| Coffee Bean Damage Rate | ≤0.1-1% |

| Conveying Angle | 0-90° |

| Cleaning Method |

- Split hose - Air gun blowing - Dry brushing - Optional CIP/WIP |

| Structure Material | 304/316 stainless steel machine head and hopper; Food-grade hose |

| Installation & Layout |

- Small footprint, detachable and portable - Mobile or fixed base - Can be connected to roasters, destoners, color sorters, packaging machines, silos, etc. - Customizable multi-point feeding or discharging |

| Noise | 68-75 dB |

| Applicable Materials | Coffee beans, roasted beans, ground granules |

| Optional Accessories | Level sensor, PLC control, frequency converter, mobile caster, sealed hopper |

Flexible Screw Conveyor for Coffee Beans Case Studies

In a large green coffee bean processing plant in Brazil, the large-diameter Flexible Screw Conveyor for Coffee Beans is used to transport dried green beans from the drying platform to 8-meter-deep silos. Its flexibility adapts to the steep entry angle, replacing traditional and easily clogged bucket elevators, achieving zero-clogging entry. In a US-based single-origin coffee company, an anti-static flexible spiral conveyor distributes different flavors of coffee powder from the grinder to their respective packaging machine hoppers. Its anti-adhesion properties allow for quick cleaning when switching between different flavors, improving the flexibility and efficiency of small-batch, multi-variety production.

The Flexible Screw Conveyor for Coffee Beans does not damage coffee beans during transport, and the equipment is lightweight and easy to move. Coffee beans naturally contain oils, especially after roasting; long-term transport can lead to oily residue buildup on the inner walls. Piping materials that are not prone to grease adhesion should be selected, and the equipment design should facilitate easy disassembly. A hygienic, quick-release structure allows operators to quickly open the pipes for manual cleaning or connect to a CIP system for automated flushing and disinfection. To reduce noise, a low-speed, high-torque geared motor can be used. During installation, ensuring the pipes are securely supported and avoiding unnecessary vibrations will also reduce operating noise.