Flexible Screw Conveyor For Milk Powder

Wednesday December-10 2025 08:29:42

Flexible Screw Conveyor For Milk Powder reduces the contact between milk powder and air during transport, lowering the risk of moisture absorption, clumping, and dust. The conveyor can typically transport 1 to 5 tons of milk powder per hour, with the specific capacity depending on the pipe diameter, the diameter of the helical blades, and the helical rotation speed. Conveying distances can reach 15 to 50 meters, and the inclination angle is typically 30° to 45°, even reaching 90° in special designs; the larger the inclination angle, the smaller the conveying capacity. The minimum bending radius is generally 2.5 to 3 times the pipe diameter, while the helical shaft rotation speed is typically controlled at 80 to 200 revolutions per minute to prevent milk powder breakage or separation.

Flexible Screw Conveyor for Milk Powder Design

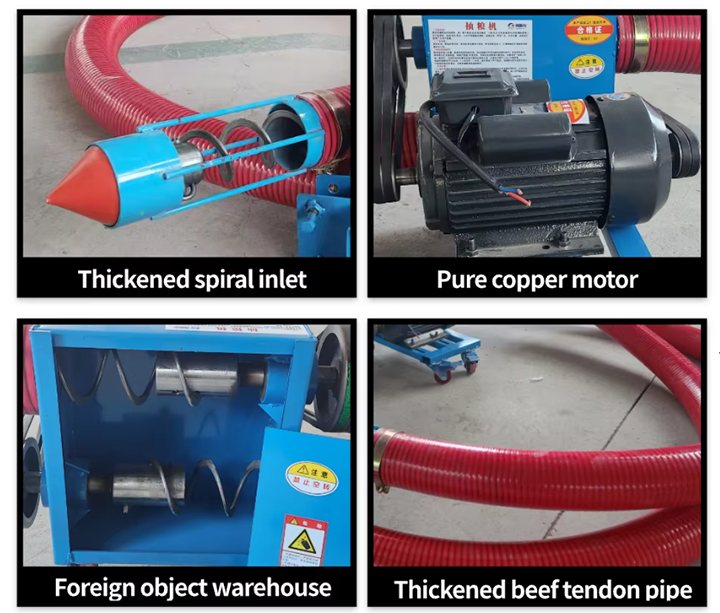

The Flexible Screw Conveyor for Milk Powder consists of a flexible helical shaft, hoses, a drive unit, and inlet/outlet ports. The flexible helical shaft is made of wear-resistant, corrosion-resistant spring steel or food-grade stainless steel and is wound around a rigid mandrel. Enclosed within a flexible conveying tube, it generates axial thrust through rotation, propelling the material forward. The flexible conveying tube is typically made of food-grade material with an extremely smooth inner wall and a low coefficient of friction, ensuring smooth flow of milk powder without residue. Its flexibility allows the equipment to navigate around obstacles, and the sealed pipeline reduces milk powder loss. The drive unit provides the power source for the machine's operation, the feed hopper design often considers anti-bridging and controllable feeding, and the discharge port can be customized according to downstream equipment interfaces.

What are the advantages of the Flexible Screw Conveyor for Milk Powder for conveying milk powder?

The low-speed, continuous pushing motion of the Flexible Screw Conveyor for Milk Powder minimizes impact on milk powder particles, preventing particle breakage, heat accumulation, and fat separation, thus preserving the original physical properties of the milk powder. The completely sealed system prevents the milk powder from getting damp or contaminated during transport and also prevents leakage. One unit can convey multiple different formulas of milk powder, reducing the cost of purchasing separate machines. Its flexibility allows for flexible layout within complex factory buildings, bypassing beams, pipes, or other equipment, making excellent use of space. The flexible conveying pipe is elastic, easily bent, and can be completely removed from the auger shaft, which has no welding or assembly points, allowing for direct and complete removal from the pipe, achieving quick and thorough disassembly.

What types of Flexible Screw Conveyor for Milk Powder are available?

Flexible Screw Conveyor for Milk Powders can be selected from three common types based on installation requirements: fixed, mobile, and inclined.

Mobile Flexible Screw Conveyor for Milk Powder: Equipped with casters, it can move flexibly between different workstations, suitable for small-batch, multi-batch production or applications requiring frequent switching of conveying points, such as pilot lines or small packaging stations. The conveying capacity is adjustable according to the auger diameter, generally around 5 m³/h, and the length is typically 2-6 m. Variable frequency motors are often used to adjust the conveying volume.

Fixed Flexible Screw Conveyor for Milk Powder: Fixedly installed in a specific location on the production line, serving as a permanent connection between key links such as the raw material silo, mixer, and packaging machine. It can convey milk powder at a capacity of over 10 m³/h, with a standard length of 3-12 m. It features a powerful motor, enabling long-distance, stable, continuous conveying.

Inclined/Vertical Conveying Type: Can be inclined or near-vertical at various angles depending on the process layout. The inclination angle of the flexible screw conveyor generally does not exceed 30°–45° to prevent powder backflow or blockage. The lifting height can reach 6-8 m. The conveying efficiency when inclined is approximately 70%-80% of that in the horizontal state, requiring a corresponding increase in motor power. The design can be equipped with multiple inlet and outlet layouts for convenient process integration.

Flexible Screw Conveyor for Milk Powder Price

The price of a Flexible Screw Conveyor for Milk Powder varies depending on the model, pipe diameter, length, material selection, and functional configuration. For equipment with basic functions, a conveying capacity of approximately 1-2 tons/hour, and a length of 5-8 meters, the price is approximately $2,000 to $5,000. For equipment with a capacity of over 5 tons/hour, a length exceeding 15 meters, constructed entirely of sanitary stainless steel, equipped with a CIP system, explosion-proof motors, or customized inlet/outlet interfaces, the price may rise to $7,000 to $10,000 or even higher.

Flexible Screw Conveyor for Milk Powder Application Scenarios

The Flexible Screw Conveyor for Milk Powder can be used in various applications, including raw material receiving and storage, batching and mixing processes, packaging line feeding, and recycling of powder and debris.

Flexible Screw Conveyor for Milk Powder transports raw milk powder unloaded from bagged or bulk tank trucks to large silos or intermediate storage silos; it transports base powders and nutrients of different formulations from storage silos to high-precision mixers; it acts as a stable supply bridge between buffer silos and automatic packaging machines, ensuring continuous packaging; it connects to ton bag unloaders or small bag feeding stations to transport unpacked milk powder to downstream processes in a dust-free manner; and it collects spilled powder or defective products generated during packaging and returns them to the main process for reprocessing.

Flexible Screw Conveyor for Milk Powder Suppliers

Flexible Screw Conveyor for Milk Powder is a commonly used conveying equipment, and there are many suppliers. Some specialize in manufacturing machine materials, while others excel in the precision of functions. Dahan Machinery has approximately 15 years of experience in manufacturing conveyor machines. The materials used for the machine's screw shaft and hoses meet international hygiene standards, and they offer various models and customization services. They can design conveyor solutions according to the production line layout, with short delivery cycles, completing production and shipping within 1-2 weeks to meet urgent production needs.

The Flexible Screw Conveyor for Milk Powder offers advantages over other conveying equipment. For example, pneumatic conveying can lead to powder breakage or grading, rigid conveyors are difficult to clean and can cause batch contamination, and open conveyors generate dust and waste. The Flexible Screw Conveyor for Milk Powder, however, maintains flexible conveying without damaging the powder, wasting raw materials, or facilitating cleaning, making it a solution for flexible milk powder conveying.