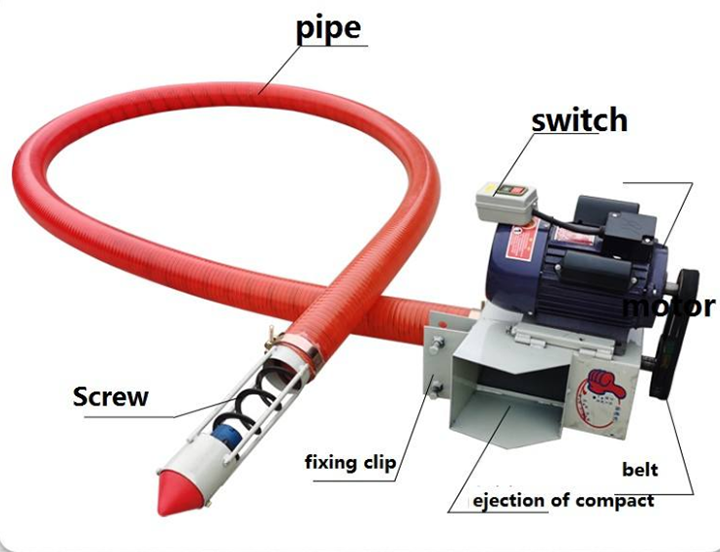

Flexible Screw Conveyor For Pellets

Wednesday December-03 2025 16:58:04

Flexible Screw Conveyor For Pellets offer high flexibility as they can bend freely when conveying granular materials. They are suitable for conveying granular materials with diameters ranging from 0.1 mm to 20 mm, regardless of whether the material is spherical, cylindrical, or irregularly shaped, as long as it has good flowability.

The conveying capacity typically ranges from 1 to 30 tons per hour, with motor power between 0.25 and 7.5 kW, resulting in lower energy consumption than traditional rigid screw conveyors or pneumatic conveying systems. Equipment length is typically 3 to 12 meters, with custom designs reaching 20 meters; standard diameters range from 40 mm to 200 mm, with 65 mm, 90 mm, and 125 mm being the most common. For fragile particles, their low-shear, gentle conveying characteristics reduce breakage, typically keeping the breakage rate below 1%. The hose is usually made of wear-resistant polyurethane or food-grade polyethylene, while the internal spring is made of high-strength carbon steel or stainless steel, ensuring durability.

Flexible Screw Conveyor for Pellets Design

The Flexible Screw Conveyor for Pellets design revolves around the flexible conveying of granular materials. The auger is typically made of high-strength alloy steel or stainless steel, capable of withstanding wear. The conveying tube is made of wear-resistant plastic or stainless steel with smooth walls to reduce material resistance. The design allows for flexible selection of auger diameter, length, and tube bending angle to meet specific plant layouts. Some models also support modular design for easy expansion and maintenance. The motor, reducer, and auger are well-matched to ensure smooth and energy-efficient conveying of granular materials.

Flexible Screw Conveyor for Pellets Types

Flexible screw conveyors come in two structural types: one with the drive motor at the top of the conveying tube and the other with the drive motor in the middle of the conveying tube. Both types utilize flexible tubing, allowing for flexible arrangement according to plant layout. The top-mounted type is better suited for vertical or steep lifting, while the middle-mounted type performs better for long-distance horizontal conveying.

Top-Motor Type: The motor drives the drive head located at the top, rotating the entire auger wire. Material is drawn in through the bottom inlet and steadily pushed upwards by the rotating screw, finally exiting through the top outlet. Suitable for bottom-to-top conveying. Its conveying capacity is typically between 1 and 30 cubic meters per hour, suitable for short-distance conveying of most granular materials, such as from hopper to packaging machine or mixer.

The drive motor is located in the middle of the conveying tube: the motor drives a bidirectional output shaft, connected to two spiral steel wires: one rotating upwards and the other downwards. Granular material can be simultaneously distributed in both directions from the center point, or collected from both directions back to the center point. The advantage is a more balanced torque distribution, reducing the twisting and wear of the spiral springs, making it particularly suitable for applications with conveying distances exceeding 10 meters. Its conveying capacity can reach over 50 cubic meters per hour, but requires more space during installation.

Advantages of Flexible Screw Conveyor for Pellets

Flexible Screw Conveyor for Pellets boasts a simple structure with no bearings or seals inside the conveyor tube, avoiding the risk of lubrication contamination and reducing maintenance costs by over 40% compared to tubular chain conveyors. Compared to pneumatic conveying systems, it consumes less energy and eliminates the need for filtration systems, resulting in superior dust control. Compared to rigid screw conveyors, its flexible design allows for curved layouts without the need for multiple sections, significantly improving installation flexibility. Flexible screw conveyors can achieve multi-angle and curved path conveying; their flexible tubes can bend horizontally, vertically, or at any angle, with a minimum bending radius of 4-6 times the tube diameter, easily bypassing pipes, equipment, or other obstacles within the factory.

Prices of Flexible Screw Conveyor for Pellets

The price of Flexible Screw Conveyor for Pellets varies depending on the model, length, tube diameter, and material. Small conveyors, 1–3 meters in length and 50–80 mm in diameter, are priced between $800 and $1,500; medium-sized conveyors, 5–10 meters in length and 100–150 mm in diameter, are priced at approximately $2,000–$4,000; and custom models, 20 meters or more in length and 200 mm or more in diameter, made of wear-resistant or stainless steel, can cost $5,000–$9,000 or even higher. Furthermore, increased drive motor power and upgraded hose materials will also affect the cost of the equipment.

Flexible Screw Conveyor for Pellets Application Cases

Flexible Screw Conveyors for Pellets are used in the plastics industry to transport PE, PP, and PVC granules from storage silos to injection molding machines, with a conveying capacity of up to 10 tons/hour and a breakage rate of less than 0.5%. In feed mills, they are used to transport finished granules from coolers to packaging lines, with a throughput of up to 20 cubic meters/hour and low dust emissions. In the chemical industry, the corrosion-resistant design extends the lifespan of equipment used for conveying fertilizer or resin granules.

The Flexible Screw Conveyor for Pellets is suitable for conveying fertilizers, resins, sugars, grains, coffee beans, pills, and lightweight building material granules. Dahan Machinery can customize wear-resistant screw bodies using materials such as stainless steel, carbon steel, or plastic coatings. For control, it can integrate variable frequency speed control, automatic start/stop, or remote monitoring systems, providing diverse conveying solutions for granular materials.