Flexible Screw Conveyor For Powder

Monday December-01 2025 16:18:58

Flexible Screw Conveyor For Powder uses a motor-driven flexible helical blade to rotate at high speed within a flexible tube, propelling powder forward along the pipe. Its conveying capacity is 1–20 m³/h, depending on powder characteristics, helical pitch, and tube diameter. Horizontal conveying distances can reach 5–20 meters, and vertical lifting is typically 3–10 meters. Due to the flexible arrangement of the hose, the minimum bending radius is typically 1–2 meters; too small a radius will affect the helical rotation efficiency. Motor power generally ranges from 1.5–7.5 kW and can be customized according to the conveying capacity and material characteristics.

The Flexible Screw Conveyor for Powder is available in materials including 304/316L stainless steel, carbon steel, polyurethane hose, and nylon hose. Common hose diameters range from 60–140 mm. It is suitable for powders because the flexible helical structure continuously agitates the powder, preventing bridging and clumping. Simultaneously, the strong sealing of the hose ensures a smooth conveying path without dead angles, resulting in more stable powder flow.

Flexible Screw Conveyor for Powder Design

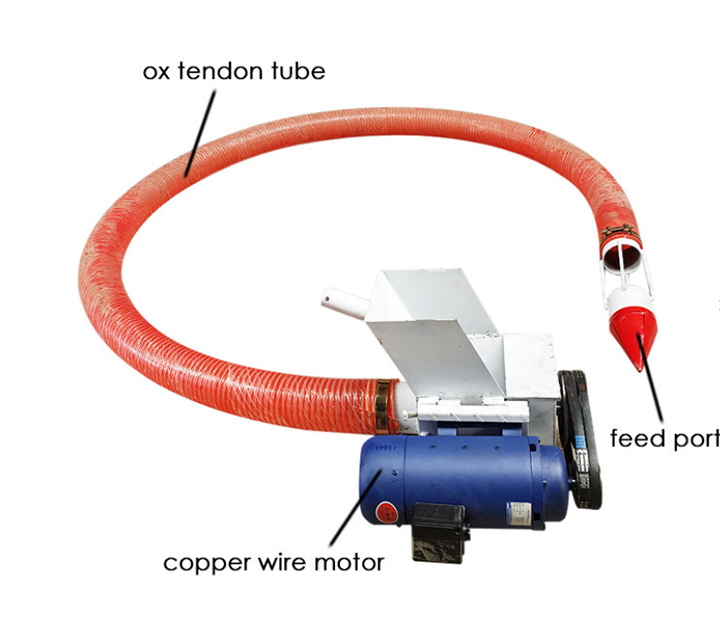

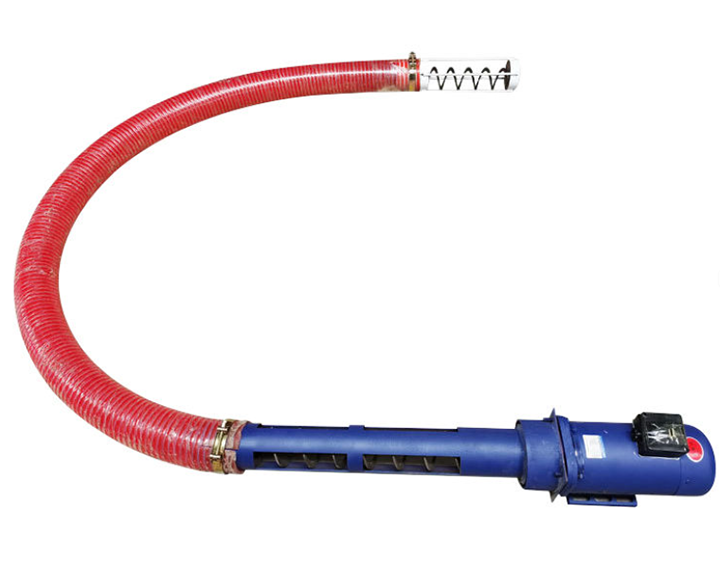

The general-purpose Flexible Screw Conveyor for Powder consists of a drive unit, a flexible screw, a conveying hose, inlet and outlet ports, and an intermediate bearing. Additional components can be added depending on the specific powder conveying requirements.

The drive unit, located at the outlet end, includes a motor and drive shaft, providing power and ensuring proper screw alignment. The flexible screw is made of high-strength spring steel or stainless steel wire, and may be coated with a polymer. The conveying hose, which wraps around the screw, is typically made of multi-layered composite materials to ensure strength, flexibility, and sealing. The inlet and outlet ports can be designed according to connection requirements and can be equipped with flanges, quick-connect clamps, etc., for easy connection to silos, mixers, packaging machines, and other equipment. For ultra-long-distance conveying, a support bearing may be installed in the middle of the pipe to prevent excessive sag or oscillation of the screw during powder conveying.

Advantages of Flexible Screw Conveyor for Powder

Compared to traditional rigid screw or chain conveyors, the Flexible Screw Conveyor for Powder can bend freely from 0-90 degrees, making it ideal for conveying powders in factory layouts with limited space or complex paths. The screw gently agitates the powder, keeping it loose and preventing agglomeration. The hose provides excellent sealing, preventing dust spillage and improving the workshop environment. The screw can be easily removed from the hose for quick cleaning. These advantages collectively address common problems in powder conveying, such as dust contamination, cross-contamination, space constraints, difficulty in cleaning, and material breakage.

Flexible screw conveyor for powder price

The price of the Flexible Screw Conveyor for Powder can be selected based on the material of the flexible hose. Different materials determine its applicable fields and price range.

Standard polyurethane hose: This material has good abrasion resistance, is transparent and allows for material visibility, has a certain degree of flexibility, and is food-grade certified. Suitable for most non-oily, non-corrosive general-purpose powders, such as flour, grains, and plastic granules. Entry-level systems are priced at approximately $2,000 - $5,000.

Food-grade and medical-grade high-grade polymer hoses: Made with special polymers that meet FDA, USP Class VI, and other certifications, offering excellent anti-fouling and easy-to-clean properties. Used in food, dairy, pharmaceutical, and high-purity chemical applications. Mid-range systems are priced at approximately $5,000 - $15,000.

Stainless steel spiral and Teflon-lined hoses: The spiral is made of stainless steel, and the hose is lined with polytetrafluoroethylene (PTFE). Offers better corrosion resistance, high-temperature resistance, and anti-adhesion properties, suitable for corrosive, high-temperature, or highly adhesive chemical powders, metal powders, etc. Higher-end systems are priced at approximately $4,000 - $10,000.

Flexible screw conveyor for powder case study

Flexible screw conveyors for powder can be well integrated into production lines and can be customized for new material handling systems or to solve problems in existing conveying processes. For example, in the food industry, it is used to transport flour, sugar powder, milk powder, and seasonings to mixers and packaging machines. In the pharmaceutical industry, it transports API raw materials and excipients from hoppers to mixers or tablet presses, meeting dust-free and easy-to-clean requirements. In the plastics and chemical industries, it is used to transport PVC powder, resin, pigments, and laundry detergent.

Flexible screw conveyors for powder require careful handling. For hygroscopic materials, both the surrounding environment and the equipment itself must be kept dry. For materials prone to adhesion, anti-stick coated screws or Teflon-lined tubes can be selected. Maintain a reasonable conveying angle. Start the machine unloaded and empty the material from the tube before stopping. Routine cleaning simply involves rotating the screw in the opposite direction to remove it from the tube, allowing for separate cleaning of the screw and the inner wall of the hose. Compared to pneumatic conveying, flexible screw conveyors typically consume less energy, requiring no compressed air; they have a very low material breakage rate, while pneumatic conveying can cause fragile particles to break. Compared to rigid screw conveyors, the biggest advantages of flexible models are their flexibility, ease of cleaning, and better sealing. Flexible screw conveyor systems for powder transport are a viable option.