Flexible screw conveyor for refractory materials

Saturday March-29 2025 17:45:34

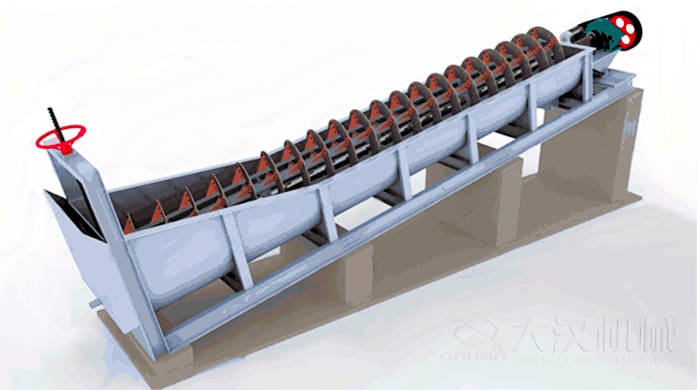

Flexible screw conveyor for refractory materials is a device used to convey refractory materials (such as refractory bricks, refractory mud, alumina powder, silica sand, magnesia sand, etc.). It uses a rotating shaftless screw to push the material in a flexible or rigid pipe, and transports the material from one location to another through the spiral blade to achieve transportation from the feed end to the discharge end. This type of conveyor is usually used in refractory production lines or refractory processing processes to achieve continuous transportation and processing of materials.

What is the working principle of the flexible screw conveyor for refractory materials?

① Feeding: Refractory materials enter the conveying pipe through a hopper or other feeding device.

② Conveying: The motor drives the screw to rotate and push the material along the pipe.

③ Discharging: After the refractory material reaches the discharge port, it is discharged by gravity or a designed mechanism. The screw shaft maintains a certain gap with the pipe wall to reduce wear and material extrusion.

Characteristics and transportation challenges of refractory materials

Refractory materials are materials that can withstand high temperatures without undergoing physical or chemical changes. They are widely used in high-temperature industries such as metallurgy, chemical industry, and electric power.

Strong wear resistance: Most refractory materials have high hardness and cause serious wear on conveying equipment.

Dust: Many refractory materials are in powder or granular form, and dust is easily generated during transportation.

Large differences in fluidity: Different types of refractory materials have very different fluidities and even have a certain viscosity.

Density differences: The density of different refractory materials varies greatly, which affects the selection of conveyors.

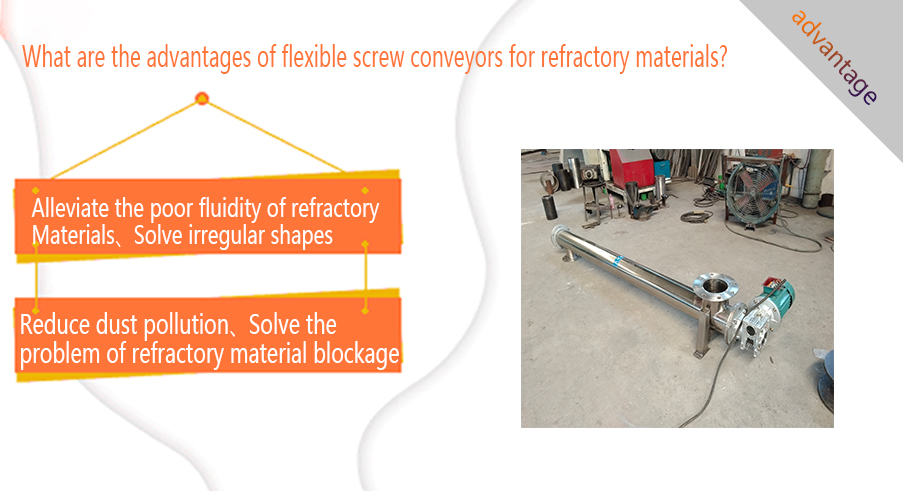

What are the advantages of flexible screw conveyors for refractory materials?

1. Alleviate the poor fluidity of refractory materials:

Flexible screw conveyors for refractory materials use smooth materials such as stainless steel to make outer tubes and spirals to reduce material adhesion and compaction. Reasonably design the gap between the spiral blades and the pipe wall to avoid excessive extrusion of materials and cause blockage.

2. Solve irregular shapes:

Flexible screw conveyors for refractory materials can better adapt to refractory materials of different shapes and particle sizes by selecting appropriate screw diameter and pitch, reduce the risk of material jamming or blockage, and help receive irregular materials discharged by the equipment.

3. Reduce dust pollution:

Flexible screw conveyors for refractory materials adopts a closed tubular structure, which can effectively wrap the screened refractory materials in the pipeline for transportation, significantly reduce dust leakage, improve the working environment, and reduce material loss.

4. Solve the problem of refractory material blockage:

The outer layer of flexible screw conveyor for refractory materials has a positive spiral forcing the material to push, and the inner layer of the reverse spiral continuously stirs, which is particularly suitable for conveying wet and agglomerated refractory materials (such as bauxite with a moisture content of 8%)

Technical parameters of flexible screw conveyors for refractory materials

|

Parameter name |

specification/range |

remarks |

|

Conveying capacity |

1-20 tons/hour |

can be customized according to material characteristics |

|

Screw diameter |

50mm-250mm |

the larger the diameter, the greater the conveying volume |

|

Conveying length |

1-12 meters |

can be customized according to needs |

|

Conveying angle |

0°-60° |

the larger the angle, the lower the conveying efficiency |

|

Screw material |

carbon steel/stainless steel/wear-resistant alloy |

select according to material characteristics |

|

Pipeline material |

carbon steel/stainless steel Stainless steel/wear-resistant plastic |

corrosion-resistant, wear-resistant |

|

Motor power |

0.75kW-7.5kW |

adjusted according to conveying capacity |

|

Power supply voltage |

380V/220V |

customizable |

|

Conveying mode |

continuous/intermittent |

selected according to process requirements |

|

Applicable materials |

powder, granular, wet materials |

suitable for refractory industry |

|

Sealing performance |

high sealing to prevent dust leakage |

dust removal system can be matched |

|

Maintenance method |

easy to disassemble, simple maintenance |

suitable for long-term operation |

Application of flexible screw conveyor for refractory materials

1. Refractory production line: Flexible screw conveyor for refractory materials needs to convey raw materials, finished products or semi-finished products from one process to another, which can realize continuous conveying of materials and improve production efficiency.

2. Refractory processing technology: Flexible screw conveyors for refractory materials needs to convey raw materials, granular materials or powdered materials to mixing, molding or sintering equipment, which can accurately and reliably complete the conveying, such as the production of refractory bricks and refractory mud.

3. Storage and loading and unloading of refractory materials: Flexible screw conveyors for refractory materials can be used to transport refractory materials from warehouses to production lines or loading equipment to achieve efficient loading and unloading of materials.

4. Mixing and batching of refractory materials: In the production of refractory materials, raw materials of different components need to be mixed and batched. Flexible screw conveyors for refractory materials can accurately convey various raw materials to the mixing equipment to ensure the accuracy and uniformity of the batching.

Flexible screw conveyor for refractory materials need to be designed and selected according to the particularity of refractory materials, especially in terms of high temperature resistance and wear resistance, while taking into account sealing, conveying capacity and maintenance convenience to meet actual production needs.