PVC conveyor belt price

Tuesday November-18 2025 16:44:17

PVC conveyor belt price is typically between $10 and $100 per square meter. Generally, standard PVC conveyor belts with a thickness of 2-5 mm and 2-3 layers cost $10-30 per square meter; medium-sized belts with a thickness of 5-8 mm and 3-4 layers cost $30-60 per square meter; belts with special colors such as blue and green, and patterns such as herringbone or grass patterns, can cost $60-100 per square meter. Plain black smooth belts are less expensive, while anti-slip or high-temperature resistant patterned belts are more expensive. These differences are mainly determined by material costs and manufacturing processes.

PVC Conveyor Belt Price

When purchasing PVC conveyor belts, more layers increase material usage and manufacturing complexity. High-temperature resistance, anti-static properties, or chemical corrosion resistance are achieved through special additives, which also increases the price. Below are some types of PVC conveyor belt prices.

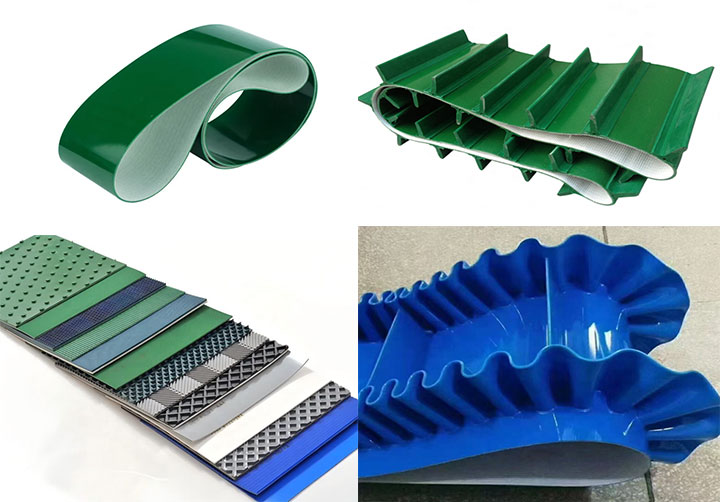

Smooth PVC conveyor belts cost $5–$30 per meter, with 1-3 layers. With a smooth surface and moderate coefficient of friction, it is suitable for packaging, e-commerce sorting, and light-load conveying applications, and operates with low noise.

Anti-slip textured PVC conveyor belts are priced between $8 and $45 per meter. These belts increase friction to prevent materials from slipping due to inclines or wet/slippery environments. They are used for fruit and vegetable sorting, airport cargo lines, and slightly inclined conveying. Herringbone patterns are suitable for medium inclines, diamond patterns for light-load conveying, and frosted patterns for quiet operation and anti-slip requirements.

Side-mounted PVC conveyor belts are priced between $20 and $80 per meter. These require additional hot-air welding of baffles and guide strips, increasing processing difficulty and cost. They can handle large inclines and vertical conveying of granules, powders, and other bulk materials. Baffle height can be customized from 20 to 100 mm.

Oil-resistant PVC conveyor belts price between $30 and $110 per meter. The surface layer is generally an oil-resistant PVC formula or a special polymer blend. They are resistant to machine oil, vegetable oil, lubricating grease, weak acids, and weak alkalis. Used in metal processing, automotive parts manufacturing, food frying production lines, and chemical workshops.

What factors influence PVC conveyor belt price?

PVC conveyor belts are composed of PVC paste resin, plasticizers, stabilizers, reinforcing skeleton materials, and cover layers. The raw materials, structural processes, and technical parameters all affect PVC conveyor belt price.

PVC Resin and Plasticizers: High-quality resins and environmentally friendly, non-toxic plasticizers are more expensive, but they ensure the conveyor belt's flexibility, durability, and compliance with special standards such as food-grade standards.

Skewer Materials: Polyester has high strength, good fatigue resistance, and is less prone to elongation, making it more expensive than ordinary canvas; nylon canvas has good toughness, impact resistance, and wear resistance, making it particularly suitable for conveying materials with high impact force, but it is easily elongated and requires frequent tensioning. Generally, nylon canvas is more expensive than polyester canvas.

Cover Rubber Thickness: The thickness of the upper and lower cover layers of the conveyor belt is a significant component of the cost. The thicker the cover rubber, the better its wear resistance, impact resistance, and cut resistance; however, more raw materials are used, and the price increases significantly accordingly.

Jointing Methods: Seamless ring joints, formed in one piece using a ring mold, are more expensive than open-end belts requiring on-site splicing. The quality differences between heat-vulcanized joints and mechanical joints also affect overall service life and cost.

PVC Conveyor Belt Suppliers

As a source manufacturer, DaHan Vibration Machinery offers competitive PVC conveyor belt price. Our products have national-level quality inspection reports, and we provide on-site cutting, splicing, installation, and after-sales service. We can take samples for on-site testing to better understand product performance and obtain a better quote.

PVC conveyor belt prices are determined by specifications and performance; thin, simple smooth belts are cheaper, while thicker, multi-layered, or specially designed conveyor belts are more expensive. The appropriate PVC conveyor belt type can be selected based on the type of material being conveyed and the required functions. By rationally evaluating the number of layers, thickness, and characteristics, costs can be effectively controlled while ensuring the conveyor belt's convenience and durability.