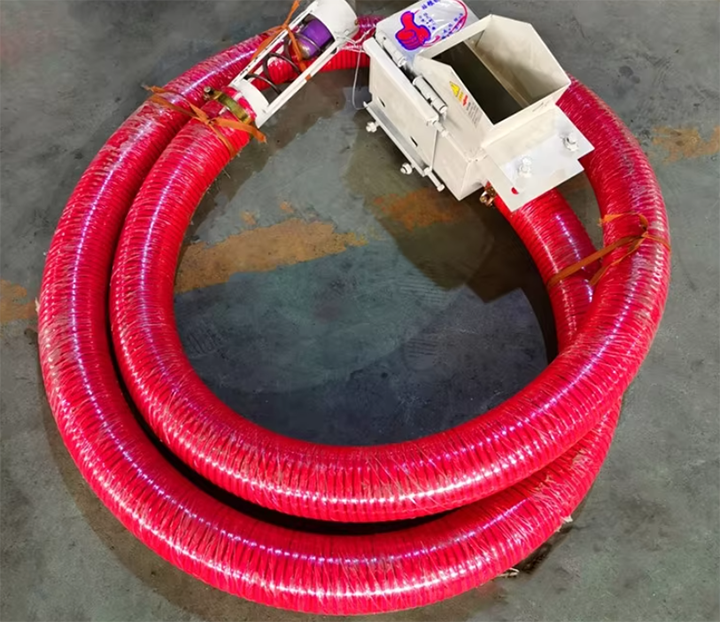

Quartz Sand Hose-Type Screw Conveyor

Thursday December-25 2025 17:17:04

Quartz sand hose-type screw conveyor transports quartz sand from one location to another through a closed, flexible pipe. The equipment can convey quartz sand horizontally, inclined, or vertically. Pipe diameters range from φ75 mm to φ300 mm, and single-unit horizontal or inclined conveying distances range from 2 to 12 meters. Multiple sections can be combined with intermediate hanger bearings for longer conveying distances. The price ranges from $1,000 to $7,000, depending on factors such as pipe diameter, length, material, and motor configuration.

Quartz Sand Hose-Type Screw Conveyor Components

A standard Quartz sand hose-type screw conveyor typically consists of a hose, a screw, a drive system, and support components. The hose is often made of wear-resistant rubber, polyurethane, or composite reinforced materials, providing both good flexibility and resistance to abrasion from the high hardness of quartz sand. The auger is made of carbon steel, alloy steel, or stainless steel, and its surface can be treated for wear resistance. Structurally, the auger maintains an appropriate gap with the hose, allowing the auger to push the material while avoiding direct friction against the inner wall of the hose during rotation. The drive unit can use an AC asynchronous motor or an explosion-proof motor, equipped with a helical gear reducer or a cycloidal pinwheel reducer to obtain stable speed and sufficient torque to meet the needs of continuous conveying of quartz sand.

Advantages of Quartz Sand Hose-Type Screw Conveyor

The advantages of the Quartz sand hose-type screw conveyor are matched with the physical properties of quartz sand. Quartz sand has a Mohs hardness of 7, which is relatively high, and it has good flowability in a dry state, but it is prone to generating dust. The hose-type screw conveyor has the following advantages through its unique structure:

The wear-resistant hose and auger buffer the impact of quartz sand during transportation, reducing particle breakage and equipment wear. The fully enclosed pipeline conveying suppresses dust emission and protects the working environment. Hose-type screw conveyors can be arranged horizontally, inclined, or with small-radius bends, adapting to complex workshop layouts and facilitating production line modifications and equipment integration. Installation and maintenance costs are lower than rigid conveyors. Screw conveyors offer uniform and adjustable feeding characteristics, making them suitable for the continuous transport of materials like quartz sand, which have relatively stable particle sizes and are dry.

Applications of Quartz Sand Hose-Type Screw Conveyors

Quartz sand is a non-metallic mineral raw material with unique physical and chemical properties, finding applications in the glass, foundry, metallurgical, and ceramic industries. The following are some applications of Quartz sand hose-type screw conveyors in conveying quartz sand.

In glass and ceramic production lines, Quartz sand hose-type screw conveyors can connect raw material silos to batching systems, achieving dust-free and leak-free closed-loop transport. In foundries, quartz sand hose-type screw conveyors transport new sand from storage tanks to sand mixers, or transport used quartz sand after it has been washed away to recycling systems. When replacing or filling quartz sand filter media in a water treatment plant, this equipment can connect to a bulk tanker truck or bagged unpacking station at one end, and extend directly into the filter tank at the other. Through a flexible hose and screw conveyor, remote, targeted, and clean filling of the filter media can be achieved, avoiding dust pollution and impurity contamination caused by manual handling.

Quartz Sand Hose-Type Screw Conveyor Case Study

A glass raw material processing plant needed to transport dried quartz sand from the storage silo to the batching machine. The plant selected a Quartz sand hose-type screw conveyor with a pipe diameter of φ150 mm and a length of 8 meters, equipped with a 5.5 kW motor and a helical gear reducer. After the equipment was put into operation, it achieved a conveying capacity of approximately 12 tons per hour, not only reducing the intensity of manual feeding but also reducing dust pollution. The flexible layout of the hose also allowed the equipment to bypass existing structures on site, saving on modification costs.

The Quartz sand hose-type screw conveyor overcomes installation limitations by cleverly combining wear-resistant flexible pipes with a rigid screw body, ensuring closed-loop conveying. When selecting a model, factors such as the particle size of the quartz sand, the conveying capacity, the distance, the layout, and environmental requirements should be considered. Then, the hose material, auger specifications, and drive power should be matched to choose the appropriate model. This equipment can meet the continuous conveying needs of multiple industries for quartz sand.