Sawdust conveying flexible screw conveyor

Tuesday March-18 2025 15:16:33

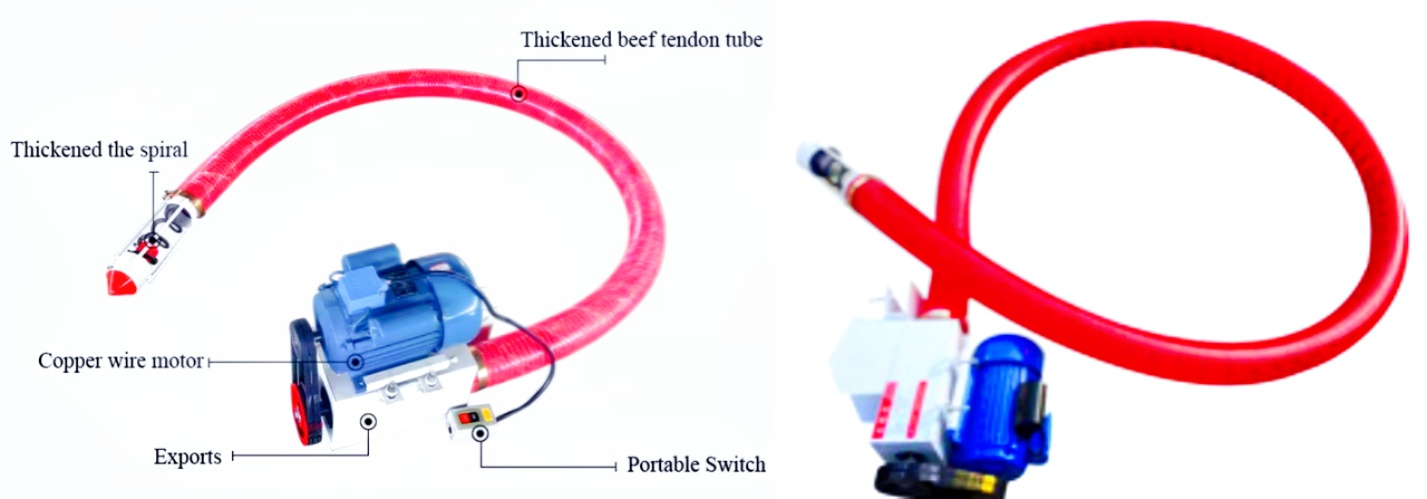

Sawdust conveying flexible screw conveyor is a conveying equipment commonly used in the woodworking industry. It is used to convey sawdust, wood chips and other powdery, granular and small block materials. It is particularly suitable for conveying light and easy-to-fly materials. This equipment is usually composed of a screw conveyor and a flexible pipe, and has the characteristics of high flexibility, simple structure and easy installation.

What is the working principle of sawdust conveying flexible screw conveyor?

The working principle of sawdust conveying flexible screw conveyor is as follows:

① Feeding: Sawdust and other granular materials enter the conveying pipe of the flexible screw conveyor from the feed port.

② Conveying: Under the push of the spiral blades, sawdust and other materials are gradually conveyed along the flexible pipe to the discharge port.

③ Discharging: When the sawdust reaches the discharge port, it can be discharged smoothly, completing the entire conveying process.

The structure of sawdust conveying flexible screw conveyor

Sawdust conveying flexible screw conveyor includes the conveying pipeline, drive device, feed port, discharge port, bracket, bearings and seals, control system, cleaning and maintenance port and protective cover. These components together ensure that the equipment can transport sawdust efficiently, stably and safely, and is suitable for a variety of industrial application scenarios.

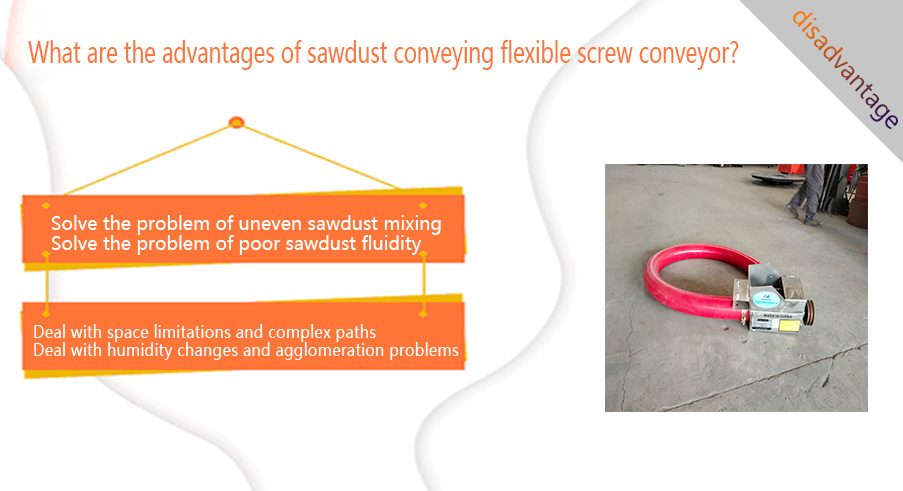

What are the advantages of sawdust conveying flexible screw conveyor?

1. Solve the problem of uneven sawdust mixing: Sawdust may be unevenly mixed during transportation, affecting subsequent processing. The spiral design of the flexible screw conveyor for sawdust transportation ensures that the sawdust is evenly advanced to avoid uneven mixing.

2. Solve the problem of poor sawdust fluidity: Sawdust has poor fluidity and is difficult to transport evenly. The spiral design of sawdust conveying flexible screw conveyor ensures that the sawdust is evenly advanced to avoid accumulation. Adjust the speed according to the characteristics of the sawdust to optimize fluidity.

3. Deal with space limitations and complex paths: Sawdust processing usually has limited space and complex equipment layout. The biggest advantage of sawdust conveying flexible screw conveyor is its flexibility. The conveying pipe can be bent, can bypass obstacles, pass through narrow spaces, and even achieve horizontal, inclined or vertical transportation.

4. Deal with humidity changes and agglomeration problems: The humidity of sawdust is greatly affected by the environment, and wet sawdust is prone to agglomeration or adhesion, affecting screening accuracy and smoothness of transportation. The spiral design of sawdust conveying flexible screw conveyor has a certain shear force, which can break up slightly agglomerated sawdust during transportation.

Technical specifications of sawdust conveying flexible screw conveyor

|

Parameters |

Specifications |

Parameters |

Specifications |

|

Conveying capacity |

1-50m³/h |

Conveying distance |

1-30 meters |

|

Conveying pipe diameter |

50-300 mm |

Spiral material |

High-strength spring steel |

|

Conveying pipe material |

Wear-resistant plastic/stainless steel |

Drive motor power |

0.75-7.5 kW |

|

Speed |

50-300RPM |

Equipment weight |

50-500 kg |

|

Feed port size |

100-400 mm |

Discharge port size |

100-400 mm |

|

Working temperature |

-20°C to +80°C |

Protection level |

IP55 |

|

Noise level |

<75dB |

Power requirements |

220V/380V, 50/60 Hz |

|

Automation control |

Optional PLC control system |

Installation mode |

Horizontal, vertical, tilted |

|

Maintenance cycle |

Every 6 months or 1000 hours |

Equipment life |

5-10 years |

|

Applicable materials |

Light materials such as sawdust, wood chips, pellets, biomass fuels, etc. |

Drive mode |

Motor drive |

Application of Sawdust Conveying Flexible Screw Conveyor

1. Wood processing industry: Sawdust is the main by-product in wood processing places such as sawmills and furniture factories. Sawdust conveying flexible screw conveyor can efficiently collect sawdust from various processing equipment and transport it to designated storage areas or subsequent processing equipment.

2. Biomass energy industry: Sawdust is a common biomass fuel used for biomass boiler combustion to generate electricity or heat. Sawdust conveying flexible screw conveyor can transport sawdust from the storage area to the feed port of the boiler to realize automatic fuel supply.

3. Agricultural field: Sawdust can be used as animal bedding and substrate for edible fungus cultivation, providing a comfortable feeding environment. Sawdust conveying flexible screw conveyor can transport sawdust to livestock and poultry houses or planting sites to realize automatic laying of bedding.

Customer cases of sawdust conveying flexible screw conveyor

|

Scenario |

Model |

Spiral tube diameter |

Conveying length |

Conveying capacity |

Motor power |

|

Waste recycling in furniture factories |

DH-300 |

φ300mm |

15m |

8t/h |

7.5kW |

|

Biomass pellet raw material conveying |

DH-250 |

φ250mm |

12m |

5t/h |

5.5kW |

|

Small batch conveying in laboratories |

DH-100 |

φ100mm |

3m |

0.5t/h |

1.5kW |

Precautions for sawdust conveying flexible screw conveyor

1. Wet sawdust conveying: It is recommended that the spiral tube tilt angle is ≤15° to avoid material adhesion.

2. Materials containing impurities: Magnetic separation device or carbide blades need to be installed.

3. Explosion-proof scene: Explosion-proof motor and nitrogen inerting are required.

4. Long-distance transportation: It is recommended to drive in sections or use intermediate feeding ports to reduce energy consumption.

Sawdust conveying flexible screw conveyor uses the rotation of the spiral blades to push sawdust and other granular materials along the conveying pipeline, and provides power support through the electric drive device to achieve efficient and flexible material conveying process.