Telescopic belt conveyor

Tuesday October-14 2025 17:50:12

What is Telescopic Belt Conveyor?

Telescopic belt conveyor are flexible conveying devices with adjustable lengths, typically with outputs ranging from 50 to 1,000 tons per hour. They are primarily constructed of carbon steel or stainless steel, and the belts are typically constructed of wear-resistant rubber or PVC, combining durability with lightweight construction.

Telescopic belt conveyors can provide automated loading and unloading services for any type of distribution center and cargo transfer center, from cartons to bags to tires, and can play a significant role. The loading and unloading is convenient, the operation is safe, reliable and efficient, which greatly reduces the labor intensity of the operator and significantly improves the loading and unloading efficiency.

Telescopic Belt Conveyor Video

The telescopic belt conveyor controls the up and down tilt and telescopic length of the machine through the control button or operating lever, especially suitable for the transportation of flat-bottomed goods such as cartons, packages, and tires.

What are the types of telescopic belt conveyors?

Telescopic belt conveyors focus on two main types: horizontal and tilting (including hydraulic models).

Horizontal telescopic belt conveyors are suitable for conveying flat materials, such as warehouse sorting and express delivery centers. Conveyor lengths are typically flexibly adjustable between 5 and 30 meters, with a conveying capacity of 100 to 500 cubic meters per hour, enabling efficient transport of small to medium-sized batches of regular materials. Their smooth conveying path reduces material drift and tipping during transport, making them particularly suitable for regular materials such as cartons and parcels.

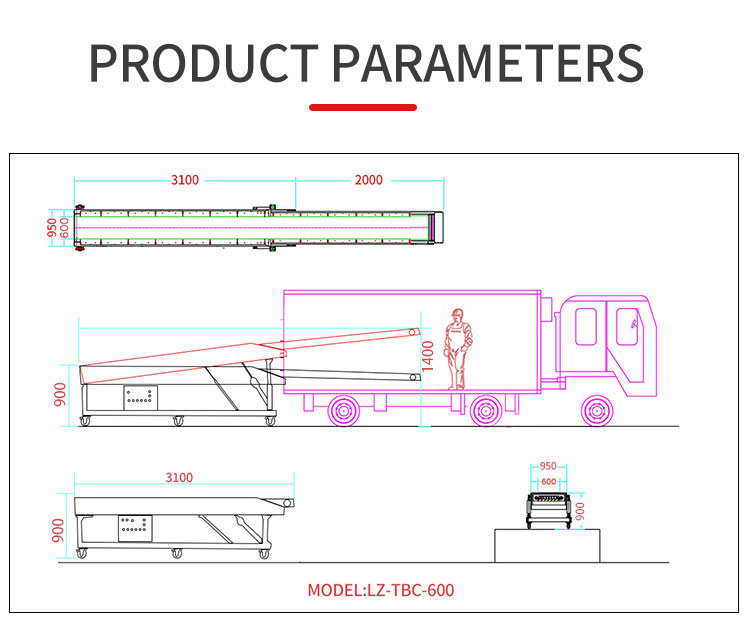

Inclined telescopic belt conveyors are designed for conveying goods across height differences, such as transferring materials between floors or loading and unloading trucks. Conveyor lengths typically range from 8 to 25 meters, and the inclination angle can be adjusted (typically 0-30°) to accommodate varying height differences. Basic models have a conveying capacity of approximately 80 to 400 cubic meters per hour. Models with hydraulic systems not only enable precise and smooth angle adjustment but also offer a greater load capacity, increasing conveying capacity to 120 to 450 cubic meters per hour, making them suitable for heavy materials such as bagged and boxed goods.

Telescopic belt conveyor technical parameters

| No | Section | Belt Width | Fixed Length | Extended Length | Total Length |

|---|---|---|---|---|---|

| 1 | 2 | 600/800mm | 4m | 3m | 7m |

| 2 | 3 | 600/800mm | 5m | 7m | 12m |

| 3 | 3 | 600/800mm | 5.4m | 6.6m | 12m |

| 4 | 3 | 600/800mm | 6m | 8.6m | 14.6m |

| 5 | 3 | 600/800mm | 4m | 5m | 9m |

| 6 | 3 | 600/800mm | 9.5m | 12m | 21.5m |

| 7 | 4 | 600/800mm | 5m | 10m | 15m |

| 8 | 4 | 600/800mm | 6m | 12.6m | 18.5m |

| 9 | 4 | 600/800mm | 7m | 14.6m | 21.6m |

| 10 | 4 | 600/800mm | 6m | 12.6m | 18.6m |

| 11 | 4 | 600/800mm | 7.5m | 16m | 23.5 |

What are the characteristics of Telescopic Belt Conveyor?

Telescopic belt conveyors can automatically convey goods, and their length can be adjusted based on the distance they are conveying, saving space. They also utilize a variable frequency drive system that allows them to start and stop at any time, providing a reliable solution for automated loading and unloading. The following are some of their specific advantages.

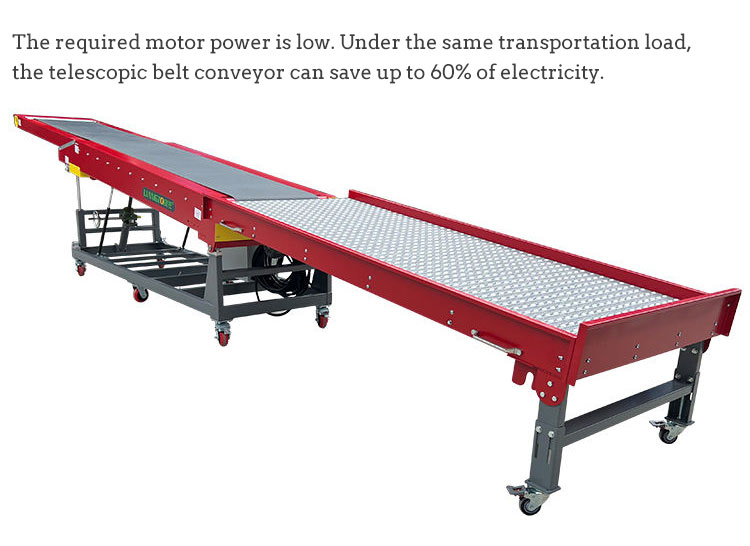

Energy saving: The required motor power is low. Under the same transportation load, the telescopic belt conveyor can save up to 60% of electricity.

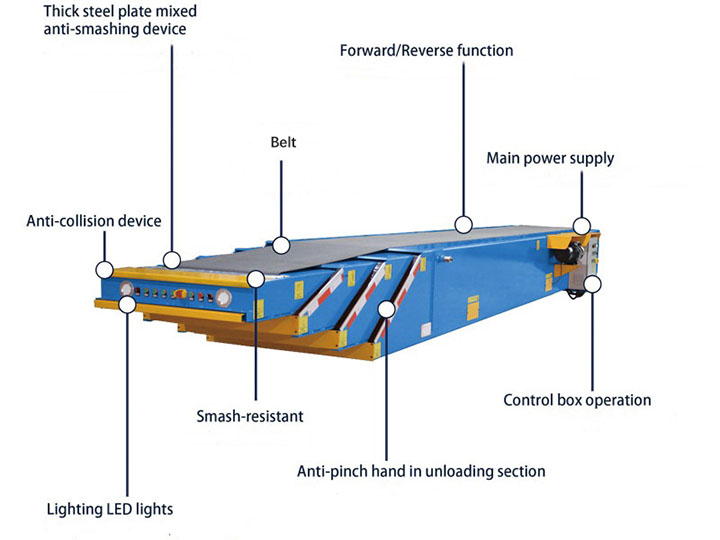

High safety level: emergency stop buttons are designed at the front and rear ends to deal with emergencies, the transmission parts are designed with rubber structures for safety protection, and the front end is designed with anti-collision devices. the

High efficiency: The conveying speed can reach 120m/min, which is about 40% faster than similar products, and the conveying goods are about 30 pieces per minute. The telescopic belt conveyor has a greater output per unit time. the

Easy to use: The unique hydraulic lifting device can perform height adjustment operations from -2 to 4 meters, and can tilt the conveyor belt downward or upward, making it easier to unload the goods.

Telescopic belt conveyor structure

The telescopic belt conveyor structure consists of five major systems: the base support system includes a fixed frame, a sliding frame, and some with adjustable legs; the conveying system is based on a rubber/PVC conveyor belt, equipped with drive rollers, bend rollers, and idler rollers; the telescopic drive system uses a motor, reducer, and transmission mechanism to adjust the conveying distance; and the tensioning system (screw or weight type) adjusts the belt tension to prevent slippage and deviation.

How does a telescopic belt conveyor work?

A telescopic belt conveyor is based on a retractable body and a belt drive. A fixed section houses a built-in drive unit (motor and reducer) that drives the belt's circulation. The retractable section, using a chain or screw mechanism, can extend and retract along a track to adjust the conveying distance. After placing material on the belt, the drive unit moves the belt at a constant speed, transporting it from the infeed to the outfeed. The conveying distance can also be adjusted by controlling the retractable mechanism.

Applications of Telescopic Belt Conveyors

Telescopic belt conveyors are used in logistics, warehousing, manufacturing, and other fields to solve the "last mile" material transportation problem. In the logistics and express delivery industry, they connect to truck carriages and accommodate different vehicle types, enabling continuous loading and unloading between sorting centers and vehicles, reducing labor and improving efficiency. In warehousing, they integrate retractable racks to connect inbound and outbound platforms with storage areas, optimizing cargo flow. In manufacturing, they adjust the belt's length according to workstation requirements to facilitate material transfer between process steps, such as in the food and electronics industries, where raw materials and semi-finished products are transported. In addition, ports and airports utilize their long-distance telescopic capabilities to adapt to loading and unloading environments and reduce workload.

Telescopic belt conveyor solutions

Customizable telescopic belt conveyor solutions are available for cargo loading, unloading, and transshipment needs in warehousing, logistics, ports, and other areas. They offer flexible telescopic length adjustments from 5 to 30 meters, variable speed control from 0.5 to 2 m/s, and are suitable for conveying cargo loads from 10 to 500 kg.

Core features include a wear-resistant, anti-deviation conveyor belt, a rust-proof chassis, and safety features such as emergency stop, infrared collision avoidance, and overload protection. They can be integrated with WMS/MES systems for automated scheduling, reducing labor costs by over 30% and increasing loading and unloading efficiency by 50%. They are suitable for e-commerce sorting, container loading and unloading, and material flow in workshops.

Telescopic belt conveyor price

Typically, a small, basic telescopic belt conveyor starts at approximately US$5,000 to US$7,000. Commonly used mid-sized models range in price from approximately US$12,000 to US$20,000. Large, high-strength, or highly automated custom systems start at $40,000. Request a quote from suppliers based on your specific requirements (e.g., length, payload, motor power, etc.).