Truck Loading Conveyor

Thursday November-13 2025 16:30:18

What is Truck Loading Conveyor?

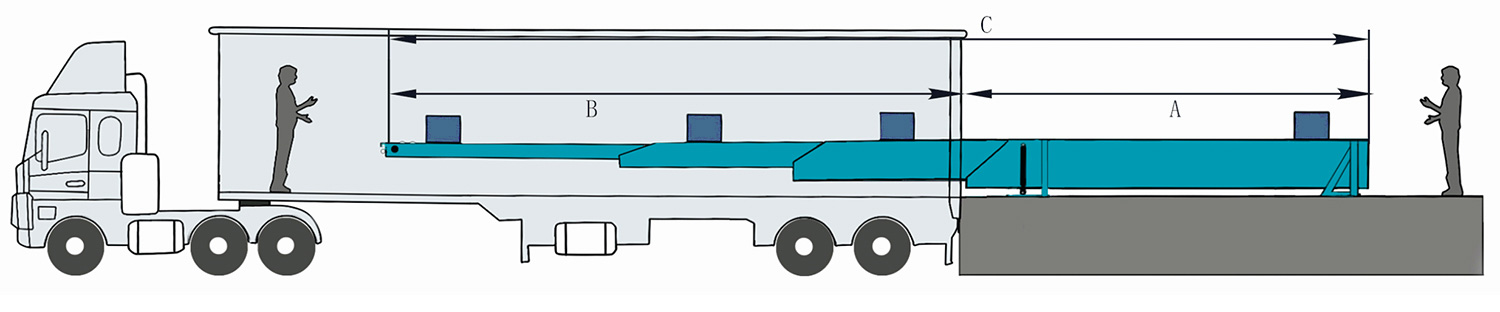

Truck Loading Conveyor is mobile and can adapt to various truck heights for loading operations. It can transport granular materials such as wheat and yellow corn, as well as powdery materials such as soybean meal and flour. Typical small-scale equipment has a conveying distance of 5-15 meters, while medium- and large-scale equipment can reach 15-30 meters. The height of the equipment is adjustable, allowing it to accommodate different trucks for conveying operations.

Truck Loading Conveyoris a kind of conveying equipment used to load bulk or bagged materials (such as sand, soil, grain, coal, etc.) onto trucks quickly and efficiently. It is widely used in logistics, ports, mines, construction sites, grain processing and other industries. It can improve loading efficiency and reduce manual operations. Truck loading conveyor generally consists of conveyor belt, support structure and power system. It can be fixed or mobile design, depending on the usage scenario.

What types of Truck Loading Conveyor are there?

Truck loading conveyors can be categorized by drive method as either hydraulic or non-hydraulic. Different types are suitable for different materials and applications. The specific differences are as follows:

Hydraulic truck loading conveyors: Driven by a hydraulic system, they offer high power and load capacity, making them suitable for heavy loads such as ores and building materials. They offer flexible conveying angles, excellent stability, and adaptability to complex working conditions, such as bumpy terrain.

Non-hydraulic truck loading conveyors: Powered by electric or pneumatic systems, common types include electric drum, belt, and chain. Electric models offer ease of operation and low maintenance, making them suitable for light to medium loads such as grain and parcels. Pneumatic models are suitable for flammable and explosive environments, such as loading chemicals, and are more suitable for stable working environments.

Truck Loading Conveyor Specifications

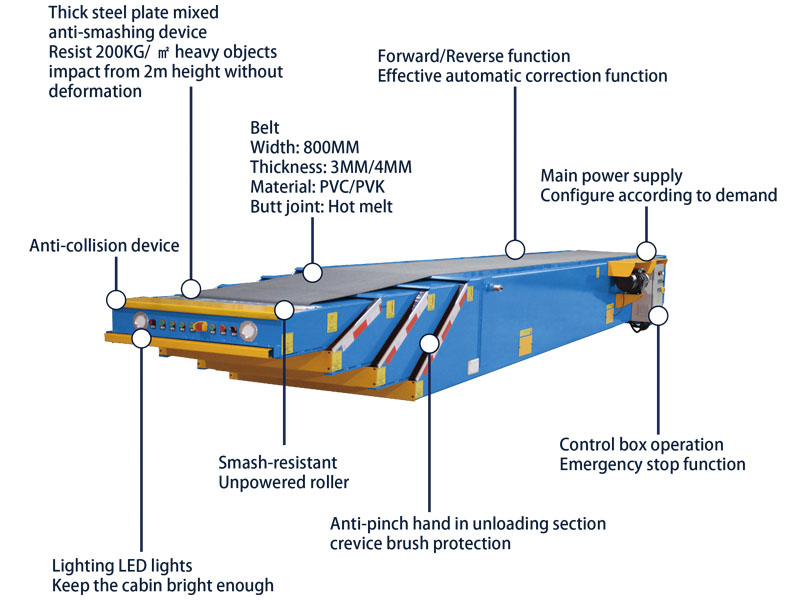

| Sepcification | Multiple Choices |

| Maximum Load | 50KG / Box. 60KG / Meter |

| Conveyance Speed | 25-40 M / Min |

| Telescopic speed | 10-20 M / Min |

| Belt Width | 800MM |

| Belt Thickness | 3MM/4MM |

| Belt Material | PVC/PVK |

| Belt Butt joint | Hot melt |

| Voltage | 380V |

| Color | Chose by You |

| Frame Material | Carbon Steel or Stainless Steel |

| Certificate | FDA/ ISO9001:2009/CE |

What are the advantages of the truck loading conveyor?

Truck loading conveyors can address space constraints. Some models are retractable and mobile, adapting to different truck sizes and loading scenarios for enhanced operational flexibility. They also address material loss and damage, as fragile materials can be subjected to excessive impact during transportation, leading to breakage or pulverization. Truck loading conveyors use variable frequency control to reduce conveying speed and minimize breakage. They are also adaptable to different truck types. Trucks vary in height and length, potentially causing inconvenience during loading and unloading. Truck loading conveyors feature adjustable conveying lengths to accommodate different truck types.

How does a Truck Loading Conveyor differ from traditional truck loading?

| Feature | Telescopic Conveyor | Manual Loading | Forklifts | Non-Telescopic Conveyor |

| Efficiency | ✅ High | ❌ Low | ✅ Moderate | ✅ Moderate |

| Labor Requirement | ✅ Low | ❌ High | ❌ High | ✅ Medium |

| Loading Speed | ✅ Fast | ❌ Slow | ✅ Moderate | ✅ Moderate |

| Cost Savings | ✅ High | ❌ High | ❌ High | ✅ Moderate |

| Safety | ✅ Safe | ❌ High risk | ❌ Forklift-related hazards | ✅ Safe |

What is the working principle of truck loading conveyor?

The working principle of Truck Loading Conveyor is to use a motor or engine to drive the conveyor belt or chain to operate continuously, automatically transferring materials (such as bulk materials, packaged items, etc.) from the feed end to the discharge end, and controlling the flow direction of the materials and loading efficiency by using the speed and inclination of the conveyor belt.

Material input: Material is placed at the starting point of the conveyor through the feed hopper of the truck loading conveyor or directly from other equipment.

Conveyor belt movement: Truck loading conveyor is driven by an electric motor and drives the circulation through the roller.

Material transportation: Materials are transported from the starting point to the end point.

Loading to the truck: The end of the truck loading conveyor is usually located above the truck cargo box, and the materials fall naturally into the truck by gravity.

What are the applications of truck loading conveyors?

When it comes to the application of truck loading conveyors, these devices play a key role in various scenarios.

Logistics centers, storage facilities and container terminals: Truck loading conveyors are used to quickly and efficiently transport goods from trucks to shelves or handling areas in warehouses. Truck loading conveyors are widely used in container loading and unloading operations. They can effectively move containers from trucks to yards or loading areas, speeding up cargo turnover.

Manufacturing assembly lines and construction sites: Truck loading conveyors are used to transport parts and raw materials from trucks to production lines. Truck loading conveyors can be used to transport construction materials such as bricks, concrete, steel, etc. from trucks to construction sites, reducing manpower handling and improving construction efficiency.

Mines, mining and agriculture: Truck loading conveyors are used to transport ore, coal, etc. from trucks to processing equipment or transportation equipment to achieve rapid loading and processing of ore. Truck loading conveyors can be used for loading and transporting agricultural products, such as transporting grain, feed, etc. from trucks to warehouses or processing equipment.

Truck Loading Conveyor Manufacturers

Dahan Vibration Machinery manufactures truck loading conveyors with belt, telescopic, or spiral configurations. Belt widths range from 700mm, and custom belt materials are available. For outdoor mobility, we also offer wheeled models. With fifteen years of manufacturing experience, we have become a trusted supplier of conveying equipment.

Truck loading conveyors play a very important role in many fields. They can significantly improve loading and unloading efficiency, reduce labor costs, and reduce damage to goods during handling.