What types of food grade conveyor belt systems are available?

Thursday November-20 2025 11:38:21

Food grade conveyor belt systems typically use PVC, PU, PE, POM, 304/316 stainless steel, or metal mesh as their core materials. These materials offer food contact safety and meet the conveying requirements of various materials, including dry, wet, oily, high-temperature, and frozen materials.

A typical food grade conveyor belt systema consists of a drive unit, frame, rollers, belt body, tensioning device, and cleaning system. Common belt widths range from 300 to 2000 mm, and belt thicknesses range from 0.8 to 12 mm. Typical module sizes for modular plastic belts are 25×50 mm, 50×100 mm, and 100×100 mm. Load capacity is typically 30–200 kg/m². Conveying speeds are generally 5–60 m/min, adjustable to 1–80 m/min using frequency converters. Motors are mostly 0.37–3 kW stainless steel waterproof motors, driven by geared motors, servo motors, or frequency converters.

Common Types of Food Grade Conveyor Belt Systems

The following are common food grade conveyor belt systems. Each conveyor belt has its own characteristics and can be used for different purposes such as high-temperature operation, cleaning, packaging, sorting, and processing.

Flat belt conveyors use single or multi-layer composite belts made of PVC/PU material and aluminum alloy or stainless steel frames. They are suitable for the rapid transport of packaged foods, baked goods, fruits and vegetables, and other light loads, with a conveying capacity of 20–150 kg/m. Their temperature resistance range is -10℃ to 80℃ (PU can reach 90℃), and they have moderate abrasion and cut resistance, but are not suitable for conveying sharp objects. PU has good oil resistance, while PVC has moderate acid and alkali resistance. The equipment supports frequency conversion speed regulation, has a tensile strength of 200–800 N/mm, offers optional non-stick coatings, and allows for quick-disassembly of the rollers for cleaning.

Fabric conveyor belts use polyester, nylon, or cotton fibers as the core layer, covered with a food-grade PVC or PU coating. They combine fiber strength with the sealing properties of the coating, making them suitable for straight or inclined conveying under certain loads, with a conveying capacity of 40–250 kg/m. Their temperature resistance range is -15℃ to 90℃, they have good abrasion resistance, can be controlled by frequency converters, and have a tensile strength of 800–2000 N/mm. The PU coating has good antibacterial properties and is used in meat cutting, food packaging, and dairy product tray applications.

Stainless steel conveyor belts are made of 304 or 316 stainless steel, with structures including flat, mesh, or chain links. They are suitable for harsh conditions such as high-temperature baking, sterilization, and pre-frying processing, with a conveying capacity of 50–300 kg/m. Their temperature resistance range is -40℃ to 300℃, and they possess extremely high abrasion resistance, cut resistance, and excellent resistance to oil and acid/alkali corrosion. The equipment can be controlled by servo or frequency converter, offering high dimensional stability and allowing for overall high-temperature cleaning. It is commonly used in processes such as baking cookies, cooling chocolate, and roasting meat.

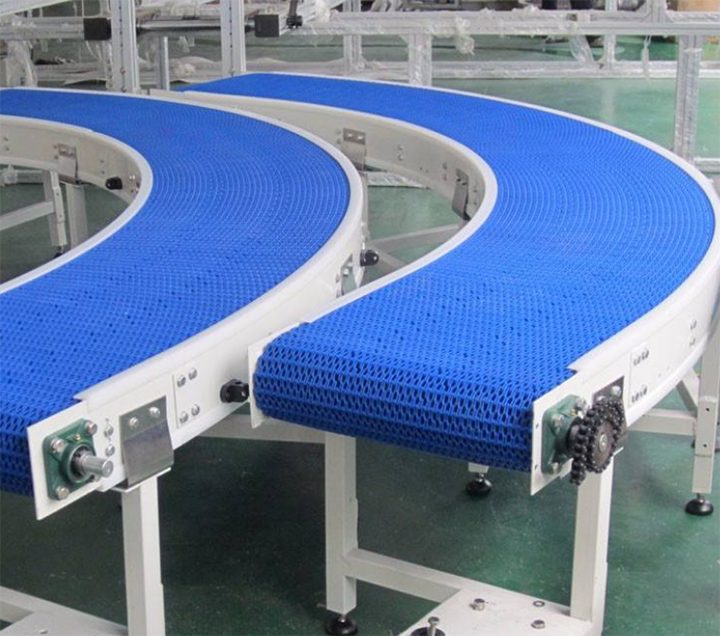

Modular plastic belt conveyors are composed of interlocking modules made of materials such as polypropylene, polyethylene, or acetal. Their flexible design allows for turning, side-bending, and multi-track conveying, and supports partial replacement and rapid maintenance. Conveying capacity is 30–200 kg/m. Their temperature resistance ranges from -40℃ to 105℃ depending on the material. PP and PE materials have excellent acid and alkali resistance, with tensile strength of 3000–8000 N/m. The modular design facilitates quick disassembly and cleaning, and antibacterial materials are available. They are suitable for processes requiring drainage or cleaning, such as those involving beverage bottles, canned goods, fruits, vegetables, and seafood.

Metal wire mesh conveyors use a woven stainless steel wire mesh structure, offering excellent air permeability, drainage, and cooling effects. They are suitable for processes such as drying, cooling, frying, and freezing, with a conveying capacity of 30–180 kg/m. Its temperature resistance ranges from -50℃ to 450℃, with good wear resistance, strong oil and acid/alkali resistance, support for servo or frequency conversion speed regulation, high dimensional stability, and chain drive is not prone to jamming. The equipment can be quickly disassembled and cleaned, but the mesh areas may require brushing. It has anti-mold and antibacterial properties and is commonly used for fried foods, baked goods, frozen foods, blanched vegetables, and candy cooling.

Other Types of Food Grade Conveyor Belt Systems

In addition to the five common types of food grade conveyor belt systems mentioned above, there are other systems. Screw conveyors are used for lifting materials vertically or in confined spaces; magnetic belt conveyors are specifically used for conveying materials containing metals or separating ferrous impurities; scraper conveyors are suitable for the closed conveying of powdered or granular food ingredients. These systems expand the spatial layout of food processing, providing continuity, lifting height, sorting capabilities, or sealed conveying capacity.

How to Choose the Best Food Grade Conveyor Belt Systems?

When selecting food grade conveyor belt systems, consider the shape, weight, moisture content, oiliness, acidity/alkalinity, and stickiness of the food materials. For sticky materials, choose anti-stick belts such as metal mesh belts; for sharp objects, choose highly abrasion-resistant belts such as stainless steel belts. Clearly define the temperature and cleaning methods (high-pressure water, steam, chemicals) during the conveying of frozen, room-temperature, baked, and fried foods. High-temperature environments require high-temperature resistant materials, such as stainless steel or Teflon-coated belts. For high-standard hygiene areas, prioritize modular plastic or stainless steel belts that are quick-disassembly compliant, have no unsanitary corners, and are easy to thoroughly clean. Determine the system's load-bearing capacity, tensile strength, and motor power based on conveying distance, load, and speed requirements. Modular plastic belts are ideal for turning. Ensure all materials comply with FDA, EU, or local food safety regulations. Balance initial investment with long-term maintenance, energy consumption, and lifespan costs while meeting performance requirements.

Food grade conveyor belt systems come in various types, from flat belts to high-temperature stainless steel structures, and modular plastic and metal mesh systems, each suitable for different food material characteristics. Flat belts and fabric belts are economical and versatile, stainless steel and metal mesh belts are suitable for harsh environments, while modular plastic belts excel in unparalleled flexibility and ease of maintenance. The selection of a conveyor belt system requires comprehensive consideration of food type, temperature, cleaning method, conveying capacity, and cost to ensure a stable, safe, and hygienic food processing process. Proper selection and maintenance of a food-grade conveyor belt system not only improves production efficiency but also reduces factory environmental costs.