Working Principle of Plate Chain Bucket Elevators

Wednesday December-17 2025 12:03:11

Plate Chain Bucket Elevators utilize a plate chain to continuously circulate and lift buckets, achieving vertical lifting and unloading of bulk materials. The lifting capacity typically ranges from 30 to 800 t/h, with higher capacities possible for large mines or cement clinker applications. Lifting heights range from 10 to 60 m, with special designs exceeding 80 m. Operating speeds are within the range of 0.3 to 0.8 m/s to ensure stability and durability under heavy loads.

How do plate chain bucket elevators work?

The working principle of plate chain bucket elevators is a continuous cyclical process, which can be divided into four stages: loading, lifting, unloading, and return.

Loading: As the chain transitions from downward to upward movement, material is scooped from the material accumulation area at the bottom of the elevator or poured in through guide channels into the buckets located at the bottom.

Lifting: Under the strong traction of the plate chain, the buckets move vertically upwards with the chain. During this stage, the material is safely enclosed within the hopper and casing to prevent spillage.

Unloading: As the hopper passes the head drive sprocket, its direction of motion changes from vertical to an arc, and finally downwards. Under the combined action of centrifugal force and its own gravity, the material is ejected from the hopper. A well-designed head shape and discharge port guide the material along a predetermined trajectory into the discharge chute.

Return: After unloading, the hopper, along with the chain, passes the head sprocket and begins its downward movement, eventually returning to the bottom, ready to begin the next loading cycle.

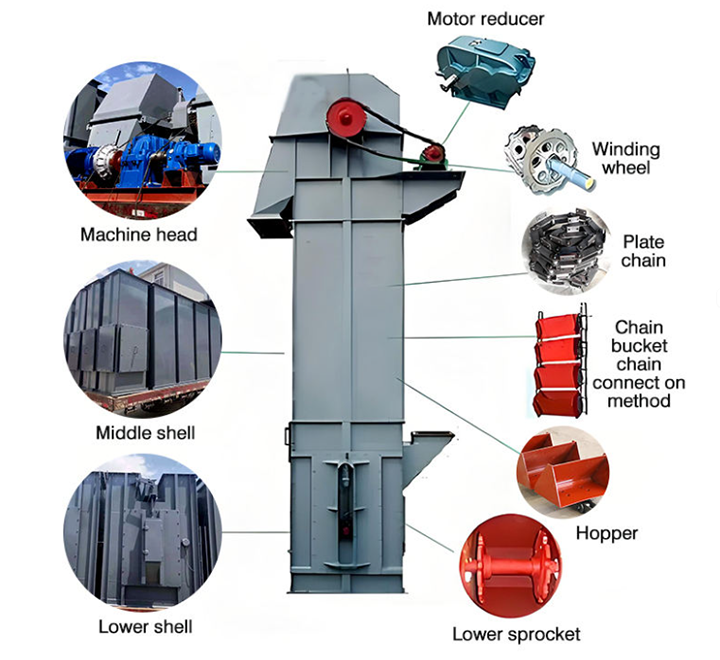

Structural Components of Plate Chain Bucket Elevators

To realize the Working Principle of Plate Chain Bucket Elevators, the plate chain bucket elevator consists of traction components, load-bearing components, a drive unit, a tensioning device, running components, and support and sealing structures.

The plate chain is composed of multiple steel plates and pins, possessing extremely high tensile strength and wear resistance, capable of withstanding heavy impacts. The buckets are typically welded or stamped from steel plates, and come in various forms such as deep and shallow buckets depending on the material characteristics. They are securely fixed to the chain using bolts or accessories. The drive unit, including a motor, reducer, and drive sprockets, provides power to the entire system and is usually located at the top of the elevator. The tensioning device, located at the bottom of the elevator, consists of a tensioning screw and a tail pulley. The chain is tensioned by adjusting the position of the driven sprocket, compensating for elongation caused by wear and thermal expansion and contraction, ensuring stable operation. The head drive sprocket and tail driven sprocket guide the chain in different directions. The casing seals and supports the entire device, preventing dust escape and external interference; internal guide rails are usually installed to restrain the swaying of the chain and buckets, reducing wear and noise.

Working Principle of Plate Chain Bucket ElevatorsFeatures

Due to their unique working principle and structure, plate chain bucket elevators offer advantages such as heavy load capacity and durability, smooth and reliable operation, strong adaptability, and controllable unloading.

The robust plate chain structure and reliable engagement with the sprockets enable the conveying of large-capacity, high-density materials. It also boasts excellent wear resistance and a long service life. The chain-sprocket engagement prevents slippage, and the guide rails reduce sway, ensuring a smooth lifting process. It is suitable for conveying high-temperature, highly abrasive, large, or sharp-edged materials, a task difficult for other types of elevators such as belt conveyors. By controlling the speed of the drive wheel, the centrifugal force can be controlled, optimizing the unloading trajectory and adapting to materials with different properties, including lumpy shapes and high temperatures.

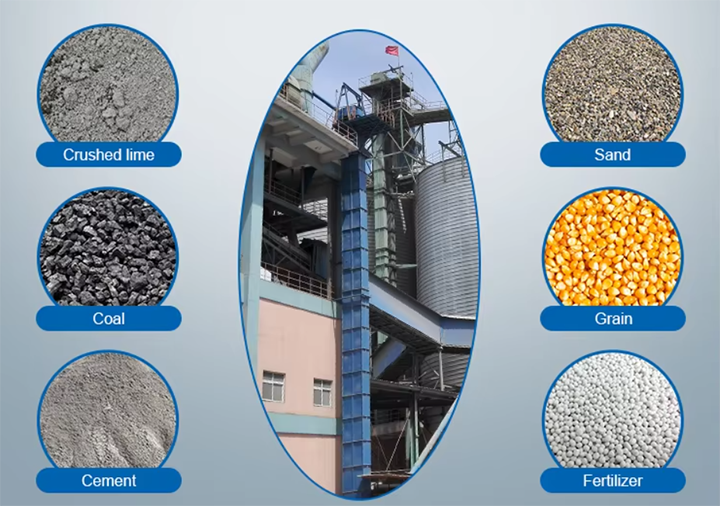

Applicable Materials for Plate Chain Bucket Elevators

Based on the working principle of Plate Chain Bucket Elevators, this machine is suitable for lifting large, heavy, high-temperature, or highly abrasive bulk materials, such as cement clinker, sintered ore, high-temperature slag, quartz sand, slag, clay, kaolin, coke, lump coal, limestone, gypsum blocks, coal gangue, crushed stone, fertilizer, and grain.

Utilizing the unique working principle of plate chain bucket elevators, plate chain bucket elevators offer a more robust structure, smoother operation, and greater load-bearing capacity compared to ring chain bucket elevators. Ring chains are lighter, slightly less expensive, and suitable for medium loads. Compared to belt bucket elevators, plate chains can handle high-temperature and highly abrasive materials, while belts are not resistant to high temperatures and sharp materials. Material breakage can be reduced through optimized design principles, such as using lower lifting speeds or larger capacity buckets to minimize material impact from falling material. As heavy-duty conveying equipment, plate chain bucket elevators provide an excellent lifting solution for bulk materials and harsh working conditions.