Oil resistant conveyor belt

It has excellent oil resistance, anti-swelling and physical and mechanical properties, and is suitable for conveying grease materials or industrial scenes that are exposed to oil pollution

Tensile strength: 800 N/mm

Cover grade: M, resistant to oils and abrasion

Operating temperature range: -10°C to +60°C

Minimum pulley diameter: 400mm

What is an oil resistant conveyor belt

The core of the oil resistant conveyor belt lies in the selection and formulation of its covering rubber. It is these special oil resistant rubber materials that enable it to resist expansion, softening, strength loss and stratification when it comes into contact with various oil substances, thereby ensuring the long-term and effective operation of the conveyor belt.

-

Oil-resistant conveyor belts are generally classified into medium and high oil-resistant grades according to ISO 1817. The cover rubber commonly used is nitrile rubber, neoprene rubber, or modified EPDM, offering both abrasion and heat resistance. Equipment width typically ranges from 400 to 2200 mm, and single-strip lengths can range from 20 to 300 meters. Standard specifications include ordinary, high-strength laminated, and wire rope core types, with tensile strengths mostly ranging from 100 to 3150 N/mm². Thickness and number of layers can be customized according to working conditions to ensure operation in oily and high-load environments.

What are the advantages of oil resistant conveyor belts?

Strong oil resistance: The specially formulated rubber materials (such as nitrile rubber NBR, styrene-butadiene rubber SBR, chloroprene rubber CR, etc.) can effectively resist the erosion of mineral oil, vegetable oil, animal oil, grease and certain organic solvents.

Stable physical properties: even in the case of long-term contact with oily substances, it can maintain a low volume change rate, as well as good tensile strength, wear resistance and tear resistance.

Wide adaptability: suitable for conveying a variety of oily materials: such as soybeans, rapeseed, oil residue, edible oil impregnation, lubricating oil, cutting fluid, tar mixture, etc.; widely used in grain and oil processing, feed mills, steel metallurgy, petrochemical, machinery processing plants, asphalt mixing plants, renewable resource processing and other industries.

What is the working principle of an oil resistant conveyor belt?

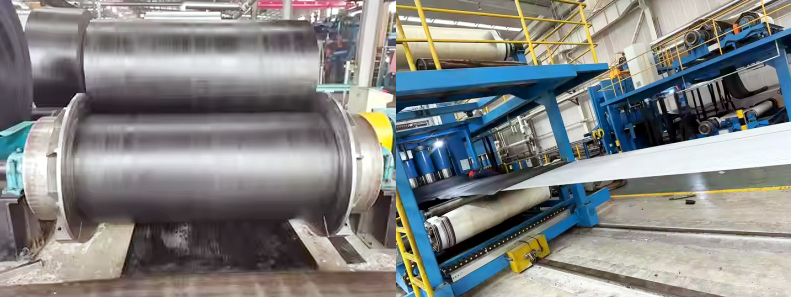

The working principle of oil resistant conveyor belt is basically the same as that of ordinary conveyor belt. It relies on the driving device to drive the conveyor belt to realize continuous conveying of materials. However, it has the ability to resist oil erosion during the conveying process and is mainly used in the conveying conditions of oil-containing materials, such as vegetable oil, mineral oil, oil residue, oil-containing particles, etc.

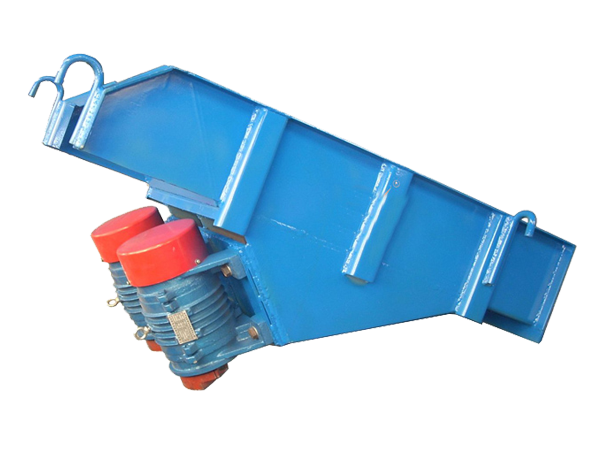

Power source drive: The driving device is driven by the electric roller or the motor + reducer combination to drive the driving roller to rotate.

Transmission friction drives the conveyor belt to run: The contact between the driving roller and the conveyor belt drives the conveyor belt to run through friction to achieve linear or inclined conveying.

Roller support: The conveyor belt is supported by upper and lower rollers during operation to avoid sagging and deviation and maintain stable tension.

Material transportation: Oil-containing materials (such as soybean meal, lubricating oil residue, industrial waste oil bags, etc.) are placed on the surface of the conveyor belt and are continuously transported to the discharge end as the belt moves.

Material of oil resistant conveyor belt

Oil resistant conveyor belt is a conveyor belt specially designed for conveying oil-containing materials or used in oily and chemical solvent environments. Oil resistant conveyor belts are usually made of the following materials:

Covering rubber: It uses nitrile rubber (NBR) with high acrylonitrile content, which has excellent oil resistance and can resist the erosion of oils and some chemical solvents.

Belt core: Commonly used cotton canvas, nylon (NN) canvas, polyester (EP) canvas or wire rope core, providing high strength and durability.

Other materials: Some oil resistant conveyor belts use polyurethane (PU) or polyvinyl chloride (PVC) as surface materials, among which PU has better oil resistance than PVC and is suitable for food processing and other scenarios.

Technical parameters of oil resistant conveyor belts

|

Parameter category |

Specific parameters |

Description |

Parameter category |

Specific parameters |

Description |

|

Belt width (B) |

300mm–2200mm |

Common specifications include 500, 650, 800, 1000, 1200mm, etc. |

Number of fabric layers (P) |

2~6 layers of EP canvas, NN canvas |

Affects the tensile strength and load-bearing capacity of the conveyor belt |

|

Strength grade |

EP100, EP150, EP200, EP300, etc. |

Indicates the tensile strength per unit width (N/mm) |

Coating rubber thickness |

Upper glue: 3~~6mm; Lower glue: 1.5~~3mm |

Coating rubber thickness affects wear resistance and oil resistance |

|

Oil resistance grade |

MOR (medium oil resistance), GOR (high oil resistance) |

MOR is suitable for vegetable oil and other light oils; GOR is suitable for heavy oils such as mineral oil |

Working temperature |

-20℃~+100℃ |

The specific temperature resistance range depends on the formula of the covering rubber |

|

Rubber type |

Mainly nitrile rubber (NBR) |

With excellent oil resistance and wear resistance |

Belt structure |

Ordinary laminated, steel wire core (ST) structure |

Steel wire core is used for long distance, large load, and impact resistance |

|

Tensile strength |

8MPa, 10MPa, 12MPa, etc. |

Related to the quality of the rubber layer and the material of the cloth layer |

Customized length |

Can be customized according to user needs, such as 50 meters/roll |

Generally 50 meters or 100 meters per roll |

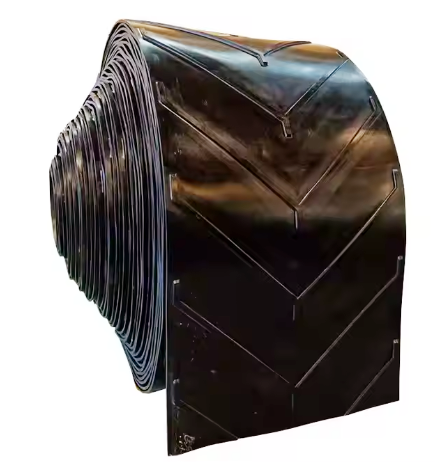

What are the structural components of an oil resistant conveyor belt?

A typical oil resistant conveyor belt mainly consists of the following parts:

Upper covering rubber: The outermost layer of the conveyor belt, which is in direct contact with the conveyed material. It withstands the impact, wear and friction of the material, and is also a key part in resisting oil erosion.

Lower covering rubber: Located at the bottom of the conveyor belt, it contacts the roller or return roller. Its main function is to protect the belt core from wear and corrosion and provide sufficient friction to ensure drive.

Belt core: This is the skeleton of the conveyor belt and the main source of its strength and stability. It bears the tension of the conveyor belt, transmits power, and provides impact and tear resistance.

Material: Usually composed of multiple layers of textiles (such as polyester/nylon EP canvas, nylon/nylon NN canvas) or steel ropes. These materials provide high tensile strength, low elongation and good dimensional stability.

Impregnation layer/interlayer glue: Located between the layers of textiles in the belt core, and between the belt core and the upper and lower covering glue. It bonds the layers together to improve the integrity, interlayer bonding strength and impact resistance of the conveyor belt.

Edge glue: Located at the longitudinal edge of the conveyor belt. It protects the belt core from erosion by the external environment (such as moisture and oil), prevents delamination, and improves the overall durability of the conveyor belt.

Application of oil resistant conveyor belts

Oil resistant conveyor belts are widely used in various industrial fields, especially in conveying materials containing grease, oil stains or oily substances, playing an irreplaceable role. For example, in the grain processing industry, it is used to transport oil crops such as soybeans, corn, rapeseed, and grain processing products containing fat; in food processing plants, oil resistant conveyor belts can effectively transport materials containing animal and plant oils such as meat, poultry, and baked goods to ensure hygiene and efficiency. In addition, in automobile and parts manufacturing, it is often used to convey metal parts and stampings with anti-rust oil or cutting oil; in metal processing and metallurgical industries, it is used to handle steel chips, scrap iron, and parts stained with lubricating oil. Even in wood processing plants, oil resistant conveyor belts can effectively deal with wood chips and board scraps containing pine oil or resin. Its unique oil resistance effectively prevents ordinary conveyor belts from expanding, deforming, and stratifying due to oil erosion, thereby significantly extending the service life of the equipment, reducing maintenance costs, and ensuring the smooth operation of the production line.

Maintenance and maintenance of oil resistant conveyor belts

Regularly check the oil resistant conveyor belt to check whether there is wear, scratches, cracks, degumming, etc. on the surface of the conveyor belt, and whether the belt core is broken or deformed. If a problem is found, it should be dealt with in time to avoid the problem from expanding. Clean the conveyor belt regularly to remove oil, dust and material residue on the conveyor belt.

When using oil resistant conveyor belts, the conveyor belt should be conveyed strictly according to the rated load of the conveyor belt to avoid overloading. Overloading will cause the conveyor belt to bear excessive tension, resulting in problems such as belt core breakage and increased wear of the cover layer, shortening the service life of the conveyor belt. Oil resistant conveyor belts should avoid working for a long time in a high temperature environment, and should be avoided as much as possible from direct sunlight. High temperature and direct sunlight will accelerate the aging and cracking of the conveyor belt, reducing the performance and service life of the conveyor belt. If necessary, measures such as shading and cooling can be taken to protect the conveyor belt.

Price of oil resistant conveyor belt

When selecting an oil-resistant conveyor belt, consider factors such as the type of material being conveyed, belt width, belt length, material, and oil resistance rating. Below are prices for different types of oil-resistant conveyor belts:

Ordinary Oil-Resistant Conveyor Belts:Typically made of a composite of nitrile rubber and PVC or ordinary reinforcing materials, used in moderately oily environments, such as conveying materials containing vegetable oils or mineral oil packaging. Prices range from $30 to $70 per meter, suitable for most light to moderate oil-resistant applications.

High-Strength Oil-Resistant Conveyor Belts:Use high-strength nylon or polyester (EP) canvas as the reinforcing material, offering higher tensile strength and impact resistance. The cover rubber remains oil-resistant rubber. Suitable for heavy-duty, long-distance oil-resistant conveying. Prices range from $50 to $120 per meter.

High-Grade Oil/Acid/Alkali Resistant Conveyor Belts: Utilize higher-quality synthetic rubber (such as hydrogenated nitrile rubber, HNBR) or special formulations, providing excellent oil, grease, and chemical resistance. Price: $80 - $200+/meter.

Food-grade oil-resistant conveyor belt: Made with non-toxic materials that meet FDA, USDA, or EU standards, ensuring safe use in oily environments where food comes into direct contact. Typically white or light-colored. Price range: $100 - $250+/meter. High hygiene standards, easy to clean.

Teflon-coated high-temperature and oil-resistant conveyor belt: Coated with polytetrafluoroethylene on a fiberglass base, offering excellent non-stick properties, chemical resistance, and high-temperature resistance (up to 260°C). While not a traditional rubber belt, it is suitable for use in extreme oily and high-temperature environments. Price range: $200 - $500+/meter (price varies significantly depending on coating thickness and construction).

Oil resistant conveyor belt manufacturer

Dahan Machinery is a company specializing in the manufacture of conveying equipment. Its products include various types of conveyor belts. According to the characteristics and applications of oil resistant conveyor belts, its manufacturers usually need to have the ability to produce high-performance rubber (such as nitrile rubber) or polyurethane conveyor belts to meet the needs of oil resistance and chemical corrosion resistance. The belt conveyor belts it produces are made of rubber, silicone, PVC, PU and other materials. Among them, PU material has the characteristics of oil resistance, corrosion resistance, cold resistance, etc., and can be used to make oil resistant conveyor belts, which can meet the needs of different users for oil resistant conveyor belts.

It can produce various types of belt conveyors such as TD belt conveyors, large-angle belt conveyors, mobile belt conveyors, etc., with models of 500mm, 650mm, 800mm, etc., and can also be specially designed according to user needs to meet the oil resistant conveying needs in different scenarios. As a direct-selling enterprise integrating R&D, production, sales and services, all contracted projects are independently constructed without subcontracting. It supports 365-day return and exchange, and the full amount will be refunded and the postage will be reimbursed for quality problems. The after-sales service is relatively complete.