Bucket elevator for paddy

Tuesday June-24 2025 17:52:44

Since paddy grains are relatively fragile, have a high impurity content, and have a certain humidity and fluidity, the design of the bucket elevator for paddy needs to take into account the requirements of anti-crushing, anti-blocking and efficient transportation. Usually, a low-speed belt or chain is used as a traction component, equipped with a deep or wide-spaced bucket to adapt to the loose density of paddy and reduce the impact on the grains.

What are the advantages of the bucket elevator for paddy?

Paddy is a lightweight particle, and the outer shell of the grain is fragile. If it is subjected to severe collision or shear force during the lifting process, it is easy to cause damage and affect the quality. The bucket elevator can control the material extraction speed by adjusting the speed, reducing the impact between materials and equipment; the bucket adopts a smooth edge design to reduce shearing and collision during loading and unloading.

paddy often contains small impurities or debris, which are easy to accumulate in the feed port, discharge port or bucket, causing blockage. The feed port structure can be optimized to prevent the feed from being concentrated too quickly and causing pile blockage, or with a screw feeder or vibrating feeder, so that the paddy enters the hopper evenly to avoid instantaneous overload.

When the lifting height is large, it is easy to cause return or insufficient lifting, especially lightweight particles such as paddy, which are easy to fall back due to airflow or inertia. The bucket distance can be set scientifically to make the bucket filling rate higher and the lifting continuity better; the overall structure is a sealed structure to prevent dust leakage.

How does the bucket elevator for paddy work?

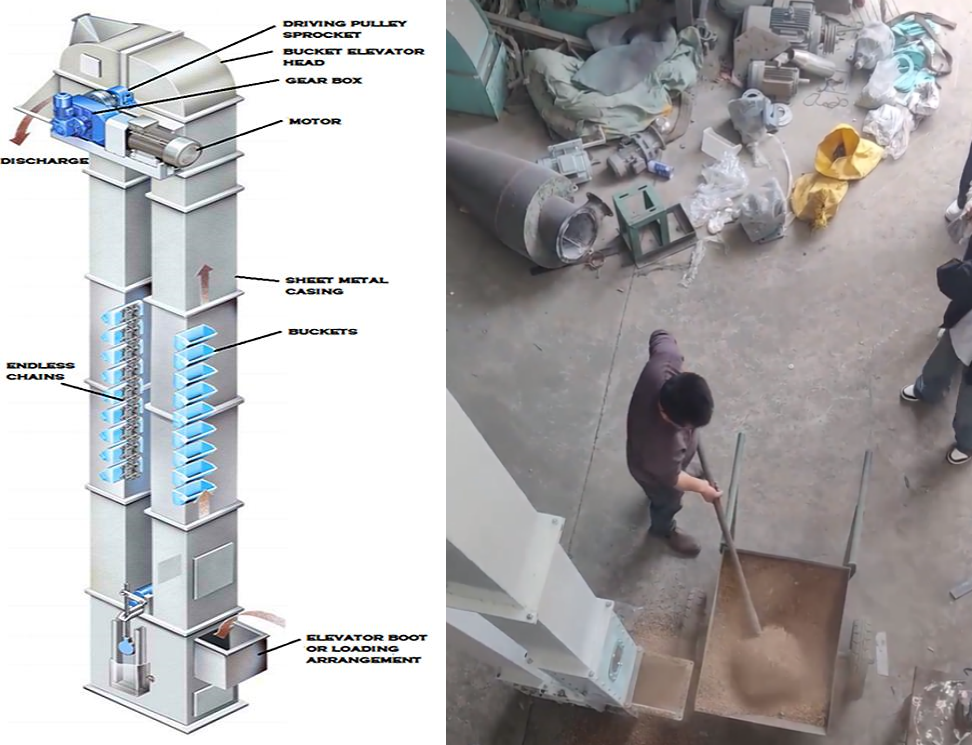

The paddy falls evenly from the feed port at the bottom of the elevator and enters the bottom casing by gravity or conveying equipment (such as a screw conveyor).

The hopper filled with paddy moves vertically upward with the traction member (driven by the motor and reducer of the top drive device), and the paddy is stably lifted in the hopper. In order to reduce the breakage of paddy, the hopper is usually designed with an arc edge and a low running speed (generally 0.8-1.5m/s) to avoid violent collisions between particles.

When the hopper runs to the top drive roller/sprocket, the traction member turns, the hopper opening faces upward and gradually tilts, and the paddy is thrown out from the front end of the hopper by gravity and centrifugal force, and falls into the upper conveying pipe or equipment (such as storage funnel, paddy mill entrance) through the discharge port.

After unloading, the empty hopper returns downward with the traction member, returns to the bottom to scoop up the paddy again, forming a continuous cycle of conveying. A tensioning device is usually provided at the bottom to maintain the tension of the traction member to avoid slipping or deviation.

What is the conveying capacity of the bucket elevator for paddy?

The conveying capacity of the bucket elevator for paddy mainly depends on its structural type (such as belt or chain), hopper specifications, lifting speed and layout. Overall, its conveying capacity is relatively stable and reliable, with strong continuity and low paddy breakage rate. It is widely used in vertical material conveying operations in paddy processing plants and grain storage systems.

|

Elevator model |

Conveying capacity range (paddy, t/h) |

Applicable scenarios |

|

TD160 (belt type) |

5~10 |

Small grain depots, small workshops |

|

TD250 |

10~25 |

General paddy mills, grain stations |

|

TD315 |

20~35 |

Medium-sized grain processing plants |

|

TD400 |

30~60 |

Large paddy mills, grain logistics systems |

|

NE series (plate chain) |

20~80 (more stable) |

High-intensity continuous operation requirements |

What is the purpose of bucket elevator for paddy?

bucket elevator for paddys are widely used in various paddy processing enterprises, grain drying systems, grain storage systems (such as silos, warehouses), large paddy processing plant raw material conveying systems, and farm particle material conveying systems, including:

paddy mills: used to vertically convey paddy from different processing steps such as cleaning, stone removal, paddy husking, paddy roughness separation, paddy milling, polishing, color sorting to grading.

Grain storage warehouses: used to lift paddy from the ground to silos for storage. The design takes into account the fragile characteristics of paddy and adopts appropriate hopper forms and operating speeds to reduce the breakage rate of paddy during transportation.

Feed mills: used to transport paddy or other grains as feed raw materials from lower positions to higher positions, such as transporting from the ground to different floors of the warehouse or sending paddy to different stages of processing equipment.

Bucket elevator for paddy continuously lifts paddy through a hopper driven by an endless belt or chain. It is suitable for vertical transportation from the ground to storage platforms, cleaning equipment or paddy mills in grain storage and processing production lines. It has the characteristics of high transportation efficiency, small footprint, and anti-breakage design (such as arc-shaped hopper and low-speed operation). Different specifications of models (such as TH type and TD type) can be selected according to paddy flow, lifting height and process requirements.