Bulk material transport bucket elevator

Wednesday June-11 2025 17:34:40

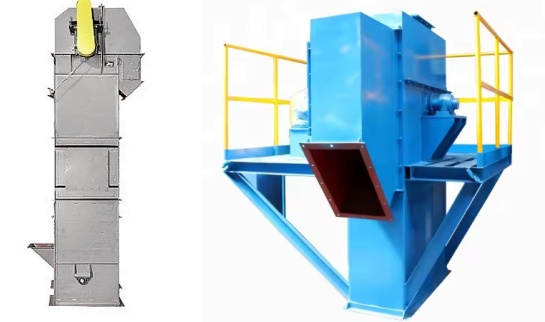

Bulk material transport bucket elevator is an efficient vertical conveying equipment, specially designed for powdery, granular or small-block bulk materials, and adapted to the characteristics of bulk materials with good fluidity, diverse density and different abrasiveness. It is fixed on the belt or chain through the hopper to lift the material from the bottom feed port to the high-position discharge port, and is widely used in grain, chemical, mining and other industries.

It has excellent lifting effect, the conveying capacity can reach 650 m³/h, the lifting height is up to 40 meters, and the running speed is adjusted according to the material characteristics (such as centrifugal unloading is suitable for fine materials, gravity type is suitable for large blocks of materials), ensuring no return and high efficiency.

Working principle of bulk material transport bucket elevator

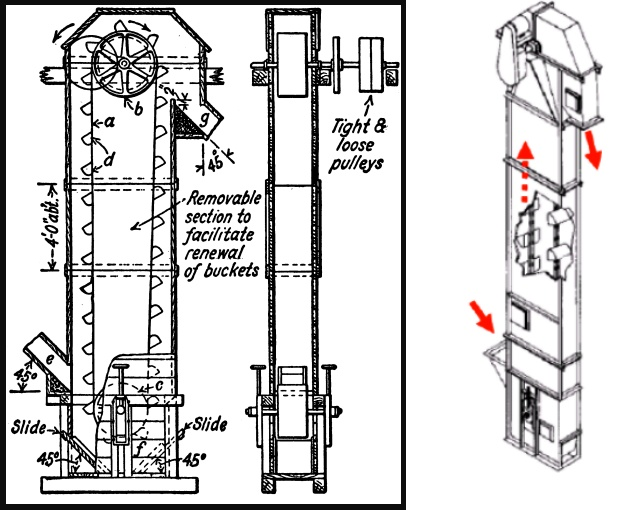

Bulk materials enter from the bottom feed port of the bucket elevator. After the motor is started, it is decelerated through the reducer and transmits power to the transmission system, driving the bucket installed on the chain or belt to move upward.

When the bucket passes through the feeding area, the material is loaded into the bucket, and then the bucket filled with materials continues to move upward with the chain or belt, and rises steadily through the guide device inside the casing. When the bucket reaches the top of the casing, the material is discharged by the bucket flipping, the scraper pushing the material, or sliding out of the opening by its own gravity. After passing the discharge area, the empty bucket continues to move downward back to the feeding area, ready to be loaded with materials again, forming a continuous cycle of lifting process.

Types of Bulk Material Transport Bucket Elevators

Centrifugal Discharge Bucket Elevator: The bucket runs at a relatively fast speed (usually above 1-2m/s), and is mainly thrown out by the centrifugal force generated by the head wheel. It is suitable for conveying powdery, granular, small block materials with low abrasiveness, such as grain, cereals, coal powder, cement raw materials, fertilizers, etc.

Gravity Discharge Bucket Elevator: The bucket runs at a relatively slow speed (usually 0.4-0.8m/s). When the bucket bypasses the drive wheel, the material is dumped out under its own gravity. It is suitable for conveying blocky, heavy, and abrasive materials, such as ore, gravel, wet sand, coke, large coal, etc.

Applicable Material Range

Bucket elevators are suitable for powdery materials, such as cement powder, lime powder, coal powder, flour, etc.; granular materials, such as plastic granules, fertilizer granules, grains (wheat, corn, soybeans, etc.); small block materials, such as gravel, ore, coal blocks, clinker, etc.

It should be noted that the material should not contain too much moisture or viscosity to prevent clogging the hopper or adhering to the inner wall of the barrel.

Bulk material transport bucket elevator performance parameter range

|

Model |

Lifting height (m) |

Conveying capacity (m³/h) |

Bucket speed (m/s) |

Power range (kW) |

|

TD160 |

≤40 |

3~12 |

1.4~1.6 |

1.5~4 |

|

TH315 |

≤50 |

15~35 |

0.5~0.75 |

3~11 |

|

NE30 |

≤45 |

20~30 |

0.5 |

4~7.5 |

|

TB500 |

≤35 |

50~90 |

1.2~1.6 |

7.5~15 |

What can the bulk material transport bucket elevator be used for?

Bulk material transport bucket elevators are widely used in industries that require efficient and vertical transportation of bulk materials.

In the grain industry, it is used to lift bulk grain, feed or grain, such as transporting wheat and corn from the ground to high-level storage silos in grain depots, or loading and unloading grain at port terminals; in the chemical industry, it can transport powdered chemical raw materials, such as fertilizers and plastic particles, to help the continuous feeding of production lines; in the mining and construction industries, elevators are often used to transport coal, limestone, crushed ore or cement clinker, which are used in mining or cement plant production; in feed and food processing, such as feed mills and flour mills, it is used to transport feed particles or starch raw materials to ensure processing efficiency.

Its conveying capacity can reach 650m³/h, and the maximum lifting height is 40 meters. It is equipped with a cleaning device and a variety of unloading methods (such as centrifugal and gravity). It can adapt to different material characteristics, operate stably, is suitable for high temperature and abrasive materials, has strong flexibility, supports multi-point feeding/unloading, and meets the needs of complex working conditions.

Bulk material bucket elevator is the core equipment for industrial bulk material vertical transportation, mainly used for continuous vertical lifting of bulk materials. Correct selection (considering material characteristics and process requirements) and good maintenance are the key to ensuring its long-term efficient, stable and safe operation. If you have specific requirements for materials, lifting height, handling capacity, etc., I can help you analyze which type or series (such as NE, TD, TH, ZL, etc.) of bucket elevator is more suitable.