Farmyard manure screw conveyor

Sunday April-27 2025 18:35:04

Farmyard manure screw conveyor is a device specially used for cleaning and conveying animal manure in farms. It is mainly used to convey animal manure, manure residue after solid-liquid separation, dry-wet separation, etc. A spiral auger structure is usually adopted, and the material is pushed by the rotation of the spiral blade to achieve horizontal, inclined or vertical conveying.

Classification of farmyard manure screw conveyors

According to different application scenarios and material characteristics, there are many types of farmyard manure screw conveyors, such as:

|

Type |

Picture |

Features |

Applicable scenarios |

|

U-type screw conveyor |

|

Open design for easy maintenance; suitable for short-distance conveying |

small and medium-sized farms |

|

Tubular screw conveyor |

|

Enclosed design to prevent odor leakage; suitable for long-distance conveying |

large farms or centralized processing centers |

|

Shaftless screw conveyor |

|

No center shaft, suitable for conveying viscous materials |

high-humidity manure processing |

U-type screw conveyor: suitable for conveying powdered, granular and small block materials horizontally or at a small inclination angle.

Tubular screw conveyor: suitable for inclined or vertical conveying of powdered and granular materials, with better sealing.

Shaftless screw conveyor: suitable for conveying materials with high viscosity and easy to entangle, such as feces with high humidity.

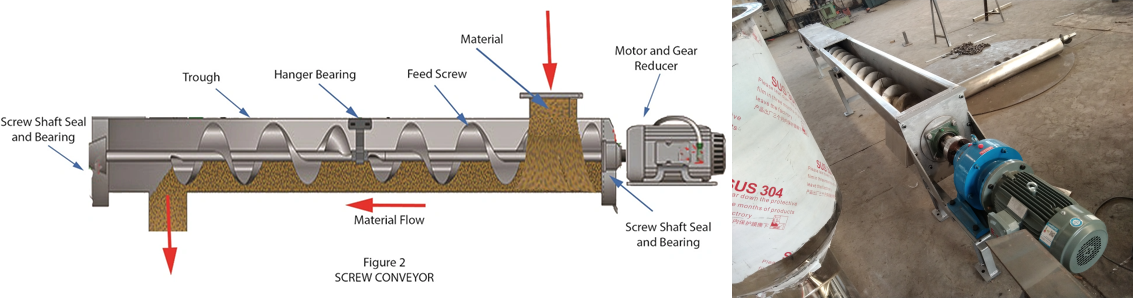

What is the working principle of farmyard manure screw conveyor?

Farmyard manure screw conveyor moves the material along the fixed shell through the rotating spiral blade, and the rotating spiral blade pushes the material for conveying.

When the screw shaft rotates, due to the gravity of the material and the friction generated by the material and the trough wall, the material can only move forward along the bottom of the conveyor trough under the push of the blade, so as to realize the horizontal, inclined or vertical conveying of feces, which is suitable for conveying viscous or block materials with poor fluidity and low water content.

What are the advantages of farmyard manure screw conveyor?

Dealing with the sticky blockage of farmyard manure: Farmyard manure has high water content and viscous texture, which is easy to accumulate and block inside the conveyor, causing shutdown. The shaftless screw design has no central shaft, and the material is not easy to entangle and block; increase the spiral spacing to improve the passability.

Solve the corrosion and wear of the conveyor: Feces contains corrosive components (ammonia, acid, etc.), and long-term use of corrosive equipment. Screw conveyors made of stainless steel or polypropylene plastic are not easily corroded by animal feces and have a long service life.

Handling odor leakage of farmyard manure: The odor spreads during transportation and pollutes the breeding environment. The fully enclosed tubular structure can prevent odor overflow and feces splashing during transportation, ensure the cleanliness of the farm space, and reduce pollution to the breeding environment and surrounding environment.

Strong conveying capacity: Farmyard manure screw conveyor can regularly control and continuously convey feces, with a conveying volume of up to 142 cubic meters per hour and a single machine conveying length of up to 60 meters, which can meet the needs of farms of different sizes.

Main parameters of farmyard manure screw conveyor (customizable)

|

Parameter |

Range/Description |

|

Screw diameter |

Common 100~400mm |

|

Conveying length |

Usually 1~20 meters, customizable |

|

Material |

Stainless steel, carbon steel, anti-corrosion coating, etc. |

|

Conveying capacity |

1~20 tons per hour, depending on the material |

|

Installation method |

Horizontal/inclined installation |

|

Drive method |

Motor drive (with reducer) |

Application of farmyard manure screw conveyor

Farmyard manure screw conveyor is used to clean livestock and poultry manure in farms, and transport manure from breeding pens to centralized treatment sites, such as manure storage sites, biogas tanks, etc., to achieve rapid cleaning and collection of manure and keep the breeding environment clean.

In the manure treatment system, as an intermediate link, the manure that has undergone dry-wet separation, fermentation and other treatment steps will be further transported for subsequent processing and utilization, such as making organic fertilizer, etc.

Transport animal excrement such as pig manure, cow manure, chicken manure, etc.;

Transport residual feed, sludge, waste, etc. from farms;

Combined with solid-liquid separator, transport the separated manure residue to the stacking point;

Combined with composting system, realize automated manure treatment process.

If you are preparing to purchase or want to know selection suggestions, drawings, quotations or product recommendations, you can contact our customer service or send an email, we will help solve the problems you are currently facing.