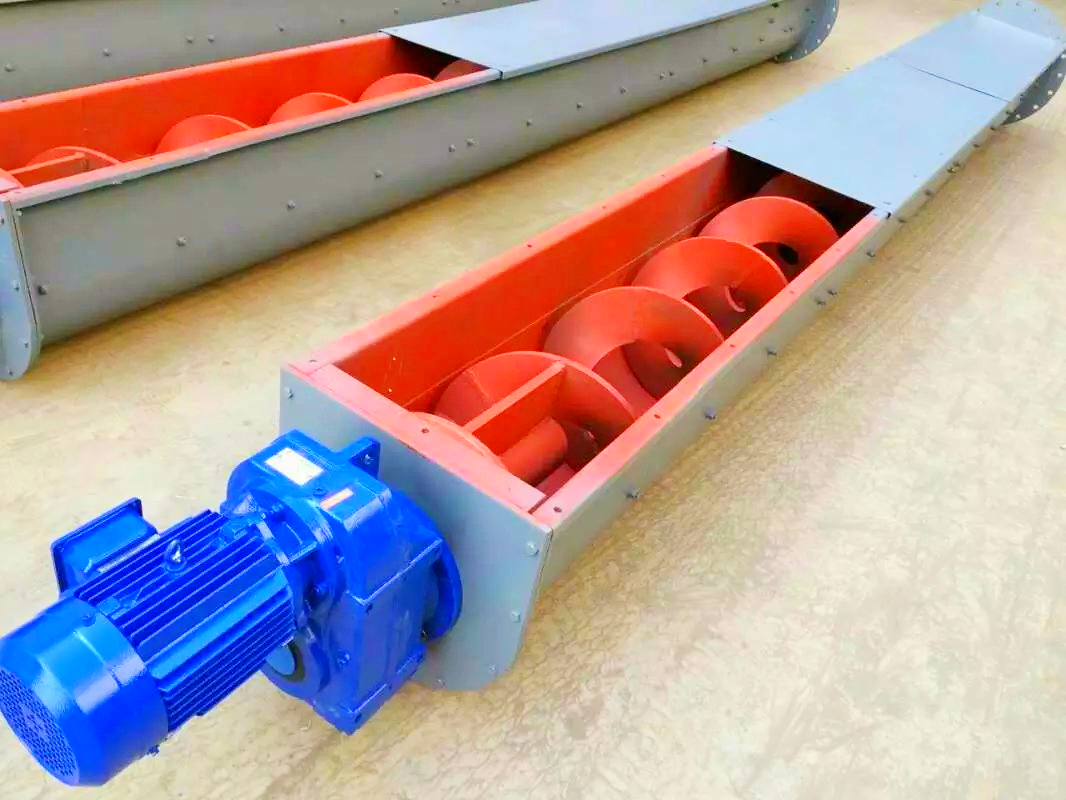

Feed mixing screw conveyor

Wednesday July-02 2025 14:14:48

What is the difference between a screw conveyor and a screw feeder?

Screw conveyors are mainly used in the "conveying" process of materials. They are suitable for moving powdered or granular materials from one location to another. They usually have a long conveying distance and can be arranged horizontally, inclined or even vertically. The core purpose of this type of equipment is to achieve continuous material transportation. Its operating characteristics are large conveying volume and adjustable speed, but generally do not pursue precise control. It is suitable for medium and long-distance material transportation in feed, grain, building materials, chemical and other industries.

The main function of the screw feeder is "feeding", that is, feeding the material from the storage bin evenly, continuously and controllably into the next process equipment, such as mixers, packaging machines, metering systems, etc. Compared with conveyors, screw feeders have a more compact structure and a short conveying distance, but require higher feeding accuracy. It is usually installed at the bottom of the silo. The design emphasizes stable flow, preventing material blockage and accurately controlling the discharge rate. It is often used in conjunction with a frequency converter, weighing system or PLC automatic control system to achieve quantitative feeding or metering control.

How does a feed mixing screw conveyor work?

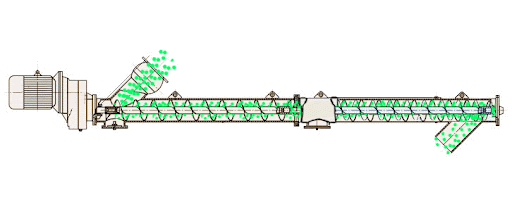

The feed (powder, granular or small pieces) enters the conveyor through the feed port, usually supplied by a hopper or the previous process. The motor drives the screw shaft to rotate, and the blades push the material forward along the axial direction. The rotation speed of the screw and the blade spacing determine the conveying efficiency.

During the pushing process, the turning of the spiral blades and the friction between the materials make the feeds of different ingredients mixed evenly. Some designs (such as double spirals or special blades) can enhance the mixing effect. The mixed feed reaches the discharge port and is discharged to the next process.

What are the advantages of feed mixing screw conveyors?

Feed mixing screw conveyors can combine the conveying and mixing functions into one, simplifying the production process. Through the continuous stirring action of the spiral blades, the mixing uniformity of the feed raw materials can be effectively improved to ensure the balance of feed nutrients.

The equipment is compactly designed and can be installed horizontally, tilted or vertically, which is suitable for feed processing plants with limited space. The modular design supports customized inlets and outlets to meet a variety of feed types and process requirements.

Model parameters of feed mixing screw conveyor

|

Model |

Screw diameter (mm) |

Conveying length (m) |

Conveying capacity (m³/h) |

Screw speed (r/min) |

Motor power (kW) |

|

MGX160-4 |

160 |

4 |

2~4 |

50~90 |

1.5~2.2 |

|

MGX200-6 |

200 |

6 |

5~8 |

40~80 |

3.0~4.0 |

|

MGX250-6 |

250 |

6 |

8~12 |

40~70 |

4.0~ 5.5 |

|

MGX300-8 |

300 |

8 |

12~18 |

30~60 |

5.5~7.5 |

|

MGX400-10 |

400 |

10 |

20~30 |

25~50 |

7.5~11 |

Application of feed mixing screw conveyor

In the feed processing industry, feed mixing screw conveyors are widely used in multiple links such as raw material proportioning, premixing, conveying and feeding, and are particularly suitable for the process requirements of conveying and mixing powdered or granular feed.

For example, in the premix production line, the equipment is often installed between the silo and the mixer to achieve the initial mixing of different trace components through uniform conveying; in the compound feed factory, it can convey materials such as corn flour, soybean meal, and puffed materials from the first floor to the mixing tower on the second floor, while avoiding the influence of material stratification on the proportioning accuracy. It is suitable for pig farms, chicken farms, aquaculture farms, and feed additive processing enterprises.

The feed mixing screw conveyor achieves synchronous and uniform mixing of multiple feed raw materials during the conveying process through its ingenious structure and continuous spiral motion. It is a very efficient and practical equipment on the feed production line.