Flat Belt portable Conveyor

Tuesday August-12 2025 17:35:02

What is a flat belt portable conveyor?

What are the advantages of flat belt portable conveyor?

The Flat Belt portable conveyor has many advantages, including preventing material scattering and accumulation, easy movement and adjustment, and can be adjusted according to different material properties to ensure stable and efficient transportation.

Solve the problem of material scattering

The conveyor belt surface of the flat belt portable conveyor is flat, which can provide a stable bearing surface for the material and reduce the shaking and scattering of the material caused by the uneven surface. Set a skirt of appropriate height on the flat belt. The skirt can effectively prevent the material from sliding to both sides during the conveying process, especially suitable for granular, powdery and other easily scattered materials.

Solve the problem of material accumulation and blockage

Control the material to fall evenly on the flat belt to avoid the concentrated accumulation of materials in a certain position. For materials that are easy to accumulate, increasing the belt speed can speed up the transportation of materials and reduce the time the materials stay on the conveyor belt, thereby preventing accumulation. For some fragile or deformable materials, the belt speed can be reduced to ensure the integrity of the materials and the stability of transportation.

Deal with the problem of inconvenient movement and adjustment

Traditional fixed conveyors are very difficult to move and adjust when the conveying line or work site needs to be changed. The conveyor body is installed on a portable frame with lockable wheels to facilitate movement between different work sites. With a retractable conveyor structure, the length of the conveyor can be adjusted according to actual needs to adapt to different working environments.

Adapting to different material characteristics

For materials with rough surfaces, a patterned conveyor belt with greater friction can be used to increase the friction between the material and the conveyor belt to prevent the material from slipping. For materials with good fluidity, a larger conveying angle is used; for materials with poor fluidity or easy rolling, a smaller conveying angle should be used to ensure that the material can be transported stably to avoid slipping or rolling.

Flat Belt portable Conveyor technical parameters

| Model |

PNL-2x 2000

|

PNL-3x 1000

|

PNL-3x 2000

|

PNL-3x 3000

|

|

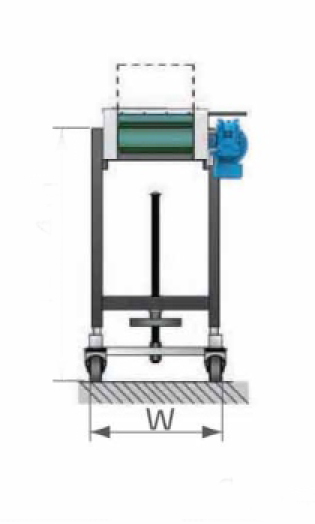

| W | inches | 20.5 | 23.2 | 23.2 | 23.2 |

| W1 | inches | 20.9 | 20.9 | 20.9 | 20.9 |

| W2 | inches | 11.8 | 11.8 | 11.8 | 11.8 |

| D | inches | 19.7 | 19.7 | 19.7 | 19.7 |

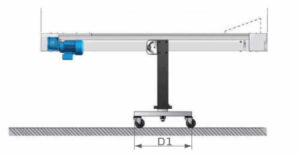

| D1 | inches | 25.6 | 25.6 | 25.6 | 25.6 |

| Length | mm | 2000 | 1000 | 2000 | 2000 |

| Model |

PNL-4x 2000

|

PNL-4x 3000

|

PNL-4x 4000

|

PNL-5x 4000

|

|

| W | inches | 28.3 | 28.3 | 28.3 | 32.3 |

| W1 | inches | 28.3 | 28.3 | 28.3 | 32.7 |

| W2 | inches | 28.3 | 28.3 | 28.3 | 23.6 |

| D | inches | 28.3 | 19.7 | 19.7 | 19.7 |

| D1 | inches | 25.6 | 25.6 | 25.6 | 25.6 |

| Length | mm | 2000 | 3000 | 4000 | 4000 |

| Model |

PNL-5x 5000

|

PNL-6x 3000

|

PNL-8x 2000

|

|

| W | inches | 32.3 | 40.2 | 55.9 |

| W1 | inches | 32.7 | 40.6 | 56.3 |

| W2 | inches | 23.6 | 31.5 | 47.2 |

| D | inches | 19.7 | 19.7 | 19.7 |

| D1 | inches | 25.6 | 25.6 | 25.6 |

| Length | mm | 5000 | 3000 | 2000 |

Flat Belt portable Conveyor product layout display

Types of flat belt portable conveyors

|

Features |

Horizontal flat belt portable conveyors |

Inclined flat belt portable conveyors |

Curving flat belt portable conveyors |

|

Images |

|

|

|

|

Main direction of movement |

Horizontal transport |

Upward or downward transport of materials |

Change the direction of material flow |

|

Belt configuration |

Flat belts running on a horizontal surface |

Flat belts with possible splints or high friction surfaces |

Curved flat belt systems |

|

Features |

Convey materials in the horizontal direction, multiple units can be used in series |

Lift materials from low to high or convey from high to low |

According to space Flexible layout to change the direction of material transportation |

|

Advantages |

Simple and efficient horizontal transportation |

Realize transportation between different altitudes, use mobility |

Allow flexible layout and integration of different processing stages |

|

Applicable scenarios |

Realize long-distance transportation of materials in the same plane |

Realize transportation of materials between different heights |

Applicable to occasions with complex spatial layout and need to change the material transportation route |

|

Industry |

Warehousing logistics, food processing, electronic manufacturing, etc. |

Mining, construction, grain processing, etc. |

Logistics industry, machinery manufacturing, etc. |

What is the working principle of flat belt portable conveyor?

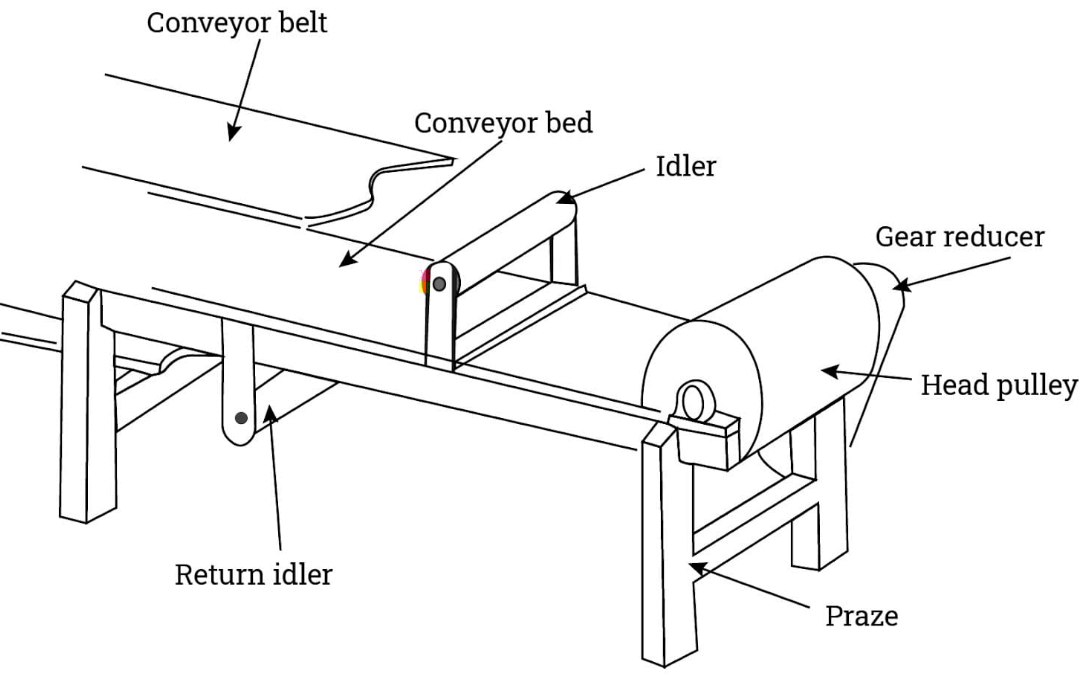

①The flat belt portable conveyor works based on the principle of friction transmission.

②The motor drives the drive roller to rotate through the transmission device. The friction between the drive roller and the conveyor belt makes the conveyor belt move. The material is placed on the conveyor belt and is transported to the designated location as the conveyor belt moves.

③During the transportation process, the roller supports the conveyor belt and the material to reduce the running resistance, and the tensioning device ensures that the conveyor belt always maintains the appropriate tension to ensure the normal operation of the conveyor.

Applicable materials for flat belt portable conveyors

Bulk or packaged materials: such as sand, ore, coal, woven bags, pallets, wooden boxes, etc.

Irregular or regular shaped materials: wood chips, wood chips, logs, etc.

Small and medium-sized block materials: such as ore blocks, coal blocks, construction waste, frozen soil, etc. (the block size needs to be controlled to avoid jamming of excessively large materials).

Powdered or granular materials: such as cement, flour, starch, talcum powder, etc.

What can a flat belt portable conveyor be used for?

Material transportation: On the production line, raw materials, parts, etc. are transported to various production stations to ensure the continuity of production. For example, in an autoportable manufacturing plant, autoportable parts are transported to various workstations on the assembly line.

Parcel handling: used for postal and express delivery outlets to transport and sort parcels. The received parcels are transported from the unloading area to the sorting area, and then transported to the corresponding loading area according to different destinations for transportation to various places.

Book transportation: In printing plants and bookstore warehouses, it is used to transport books, magazines and other publications. For example, printed books are transported from the binding workshop to the warehouse storage area, or books are transported to shelves in the bookstore warehouse for storage.

Food sorting: Food can be sorted and transported according to different specifications and qualities. For example, on a biscuit production line, biscuits of different shapes and flavors are sorted to different packaging lines.

Cargo handling: In warehouses, logistics centers and other places, it is used to move goods from one place to another, such as transporting goods from the entrance to the storage area, or from the storage area to the exit, to achieve rapid circulation of goods.

In short, flat belt portable conveyor s are general tools for improving material handling efficiency, especially for occasions that require frequent changes in working positions or short-term projects. Due to its simple structure, reliable operation, easy maintenance, and smooth transportation, it can be used in almost any occasion where various materials need to be transported horizontally or at a small angle, which can significantly improve production efficiency and reduce labor intensity.