Flexible Screw Conveyors For Metal Chips

Saturday May-10 2025 13:57:42

What is a flexible screw conveyor for metal chips?

Flexible screw conveyor for metal chips is a device that uses rotating flexible screw chips to transport metal chips in a closed pipe, easily achieving horizontal, inclined or even vertical transportation. The conveyor is often equipped with different specifications of feed and discharge ports to accurately separate debris of different particle sizes (such as 20 mesh corresponds to 0.85mm particles, 100 mesh screens 0.15mm fine chips). For example, different screen mesh sizes such as 20 mesh, 40 mesh, and 60 mesh can be configured to effectively separate coarse impurities and fine particles, separate and transport metal chips of different specifications to designated locations, improve material processing efficiency, and are widely used in mechanical processing, automobile manufacturing and other industries.

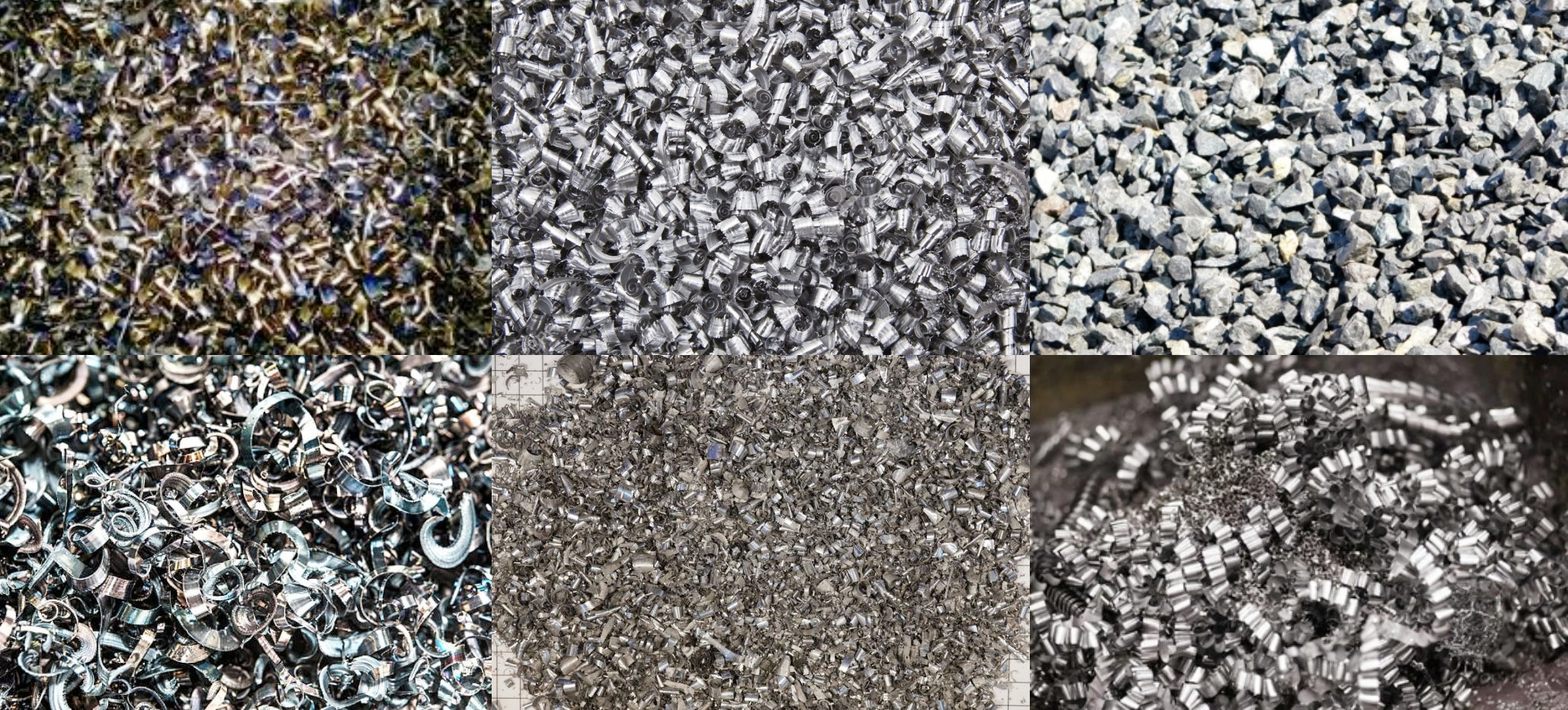

Applicable materials for flexible screw conveyor for metal chips

Dry metal chips (such as turning iron chips, steel chips, aluminum chips, etc.), particle size 1~5mm, containing a small amount of coolant

Granular or fine metal chips, uneven particle size, large density difference

Some oily metal chips (specially customized anti-seepage structure required), particle size 1~3mm

Not suitable for conveying large pieces, long strips of metal waste with strong winding properties (such as filamentary steel wire, thin strip aluminum chips, etc.), which are easy to entangle the screw and cause jamming.

What is the working principle of flexible screw conveyor for metal chips?

The flexible screw conveyor for metal chips is a device used to convey metal chips and other granular materials. Its working principle is as follows:

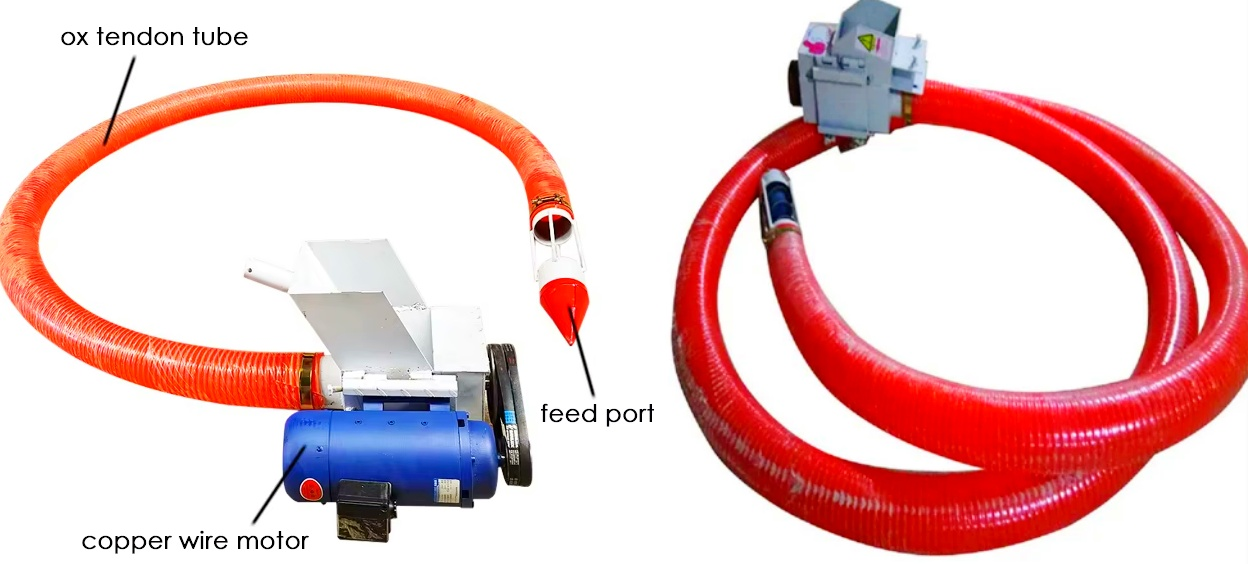

Screw conveying principle: A screw conveying screw is installed inside the equipment. When the screw rotates, the material is pushed along the conveying pipe.

Flexible structure: The screw of the flexible screw conveyor for metal chips is usually made of flexible material and can adapt to different bends and curves. This enables it to work in places with limited space and the conveying path can be adjusted as needed.

Feeding and discharging: The material enters the conveyor from the feed port. As the screw rotates, the material is gradually pushed to the discharge port to complete the conveying process.

Closed conveying: The equipment is usually designed as a closed structure to prevent material leakage and environmental pollution.

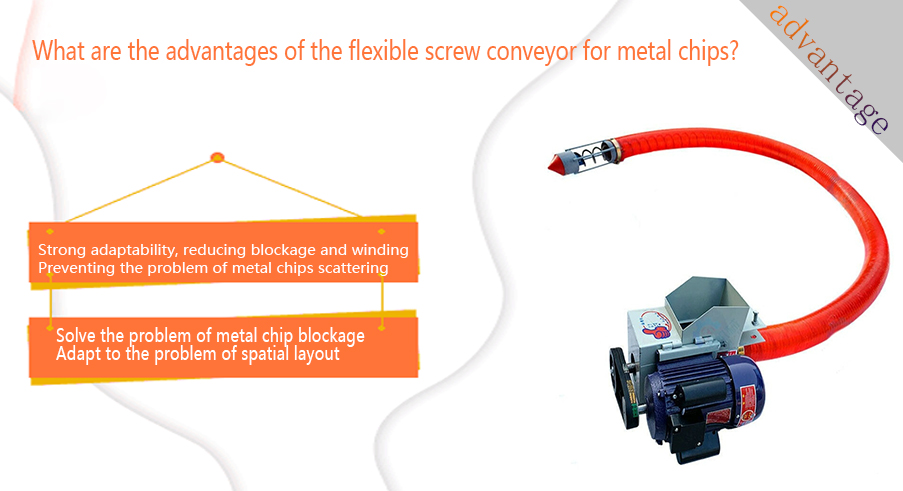

What are the advantages of the flexible screw conveyor for metal chips?

The structure of the flexible screw conveyor for metal chips is mainly composed of flexible screw auger, pipeline, drive motor, etc. Compared with the traditional rigid screw conveyor, it has the following solutions in handling metal chips:

① Strong adaptability, reducing blockage and winding

The flexible screw conveyor uses elastic steel wire auger as a conveying element. It has a certain deformability during the conveying process, can adapt to slight winding or blocking, and self-eliminate slight blockage through continuous rotation. The equipment can realize bending conveying with a smaller radius, effectively avoiding the accumulation of materials at the bend.

② Preventing the problem of metal chips scattering

The flexible screw conveyor for metal chips usually uses a closed conveying pipe, and the metal chips are pushed forward by the screw body in the pipe, which effectively avoids the problem of easy scattering of metal chips in the traditional open conveying method. Even if there is vibration or tilt during the conveying process, the closed conveying pipe can well confine the metal chips in the pipe to prevent them from scattering, reducing material waste and environmental pollution.

③Solve the problem of metal chip blockage

The spring screw structure of the flexible screw conveyors for metal chips is relatively flexible. When conveying metal chips, it can adapt to a certain degree of shape changes and material accumulation, unlike the rigid screw shaft of the traditional screw conveyor, which is easy to get stuck. Moreover, the rotation of the screw body can push the metal chips along the screw line to avoid local accumulation of materials and blockage. Reasonably select the speed of the screw shaft to avoid excessive speed causing metal chips to be thrown out due to excessive centrifugal force, and also prevent the speed from being too low, resulting in a decrease in conveying volume and material accumulation.

④Adapt to the problem of spatial layout

The flexible screw conveyor has a high degree of flexibility and can be used for straight-line conveying or curved conveying according to the space conditions on site. This allows it to be easily arranged in various complex production environments, especially in some places with narrow space or irregular layout. It can flexibly adapt to different installation locations and conveying route requirements, effectively solving the problem of limited space layout.

Mesh number of flexible screw conveyors for metal chips

|

Supply type |

Diameter range (mm) |

Mesh number range |

Applicable conveyor type |

Pipe diameter (mm) |

Remarks |

|

Fine metal chips |

0.1-1.0 |

150-600 mesh |

Flexible screw pipe machine |

50-100 |

Suitable for powder or fine particles, high sealing |

|

Small particle metal chips |

1.0-5.0 |

30-150 mesh |

Flexible screw pipe machine (standard type) |

100-200 |

Commonly seen in aluminum chips, copper chips, wear-resistant, horizontal or small angle pipes |

|

Medium metal chips |

5.0-20.0 |

2-30 mesh |

Shaftless screw pipe machine |

200-300 |

Suitable Suitable for irregular chip shipment, strong anti-winding performance, can handle oily metal chips |

|

Large metal chips |

20.0-50.0 |

Not applicable mesh |

Shaftless screw pipe machine (large pipe diameter) |

300-400 |

Suitable for large cutting edges or lumpy metal cutting edges, wear-resistant materials are recommended |

|

Metal chip |

0.1-50.0 |

Not applicable mesh |

Shaftless screw pipe machine (with drainage design) |

200-400 |

Need to be equipped with a separation device to handle liquid, suitable for complex working conditions |

Application of flexible screw conveyor for metal chips

CNC machine tool chip removal system: During turning, milling, drilling and other processing processes, metal parts will continuously produce fine or curly metal chips. If these chips are not cleaned in time, they will accumulate inside the machine tool, affecting the processing accuracy and even causing equipment failure. The flexible screw conveyor for metal chips can be directly installed at the chip trough or chip removal port at the bottom of the machine tool to lift the chips to the collection box or centralized conveyor line on the side of the machine tool.

Metal chip centralized recycling line: Large-scale machining workshops produce a large amount of metal scraps every day, and the traditional manual collection method is inefficient. Local flexible screw chip removal units are set at the bottom of multiple workstations. After the chips are transported to the main conveying pipeline, they are centrally lifted and enter the centralized silo or the entrance of the briquetting machine. The flexible structure supports multi-point feeding and multi-stage lifting layout, which is convenient for cross-regional collection and transportation.

CNC lathe automatic chip removal transformation project: Some old equipment is not equipped with an automatic chip removal system, and manual chip removal is labor-intensive. A small flexible screw conveyor for metal chips is used to quickly transform the chip removal structure without dismantling the main body of the machine tool. It can be transported vertically or obliquely to a chip collection bucket 1 to 3 meters high.

Aluminum chips are crushed and transported to the furnace feeding port: In aluminum processing plants, the crushed aluminum chips need to be quickly transported to the feeding port of the smelting equipment, but the aluminum chips have a low density and the conveying pipeline is usually complicated. The conveyor transports materials through a closed pipeline structure. The curved pipeline can be adapted to the side or top feeding of the furnace.

Automatic chip removal system for CNC lathes

Metal scrap conveying in machining centers

Centralized chip conveying in metal die-casting workshops

Front-end feeding system for small metal chip recycling devices

Flexible screw conveyor for metal chips is a device that uses a flexible screw to rotate in a pipe to convey metal chips. When choosing a flexible screw conveyor for metal chips, it is necessary to consider the conveying volume and distance, the shape and characteristics of the metal chips, the conveying environment, and the installation space and layout requirements. If you need more detailed information, such as a specific model or technical parameters, please tell the customer service about your specific needs.