Flexible screw conveyor for fine powder

Tuesday August-19 2025 14:43:34

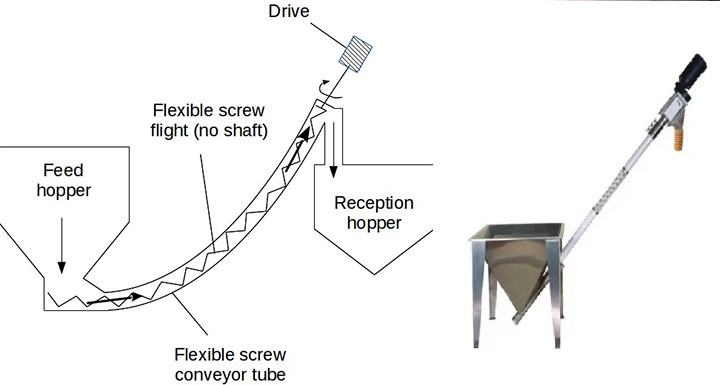

Flexible screw conveyor for fine powder is a device used to convey fine powder materials. It is suitable for powdery materials with good fluidity and low viscosity, such as flour, cement, fly ash or medicinal powder. Its core component is a flexible spiral spring with a center axis-free design to avoid material adhesion and blockage. The material is pushed along the pipeline or trough by spiral rotation. It supports horizontal, inclined (generally less than 20°) or vertical conveying. The conveying distance can reach 3-70 meters, and the conveying volume is usually less than 40 cubic meters/hour.

What is the function of a flexible screw conveyor for fine powder

The main function of a flexible screw conveyor for fine powder is to efficiently and safely convey fine, dry powdery materials from one location to another.

①Material conveying: The most basic function is to continuously convey powder materials along the pipeline through the rotating motion of the spiral. It can handle various types of fine powder materials, such as cement powder, talcum powder, flour, medicinal powder, etc.

②Prevent material adhesion: The design without a central axis reduces the blockage caused by stickiness or accumulation of fine powder, ensures smooth conveying, and is especially suitable for materials with good fluidity but easy to raise dust.

③Maintain material purity: Made of stainless steel or carbon steel, with a smooth surface, no lubricating oil is required to avoid contaminating fine powders, and is suitable for scenes with high hygiene requirements such as food and pharmaceuticals.

④Multi-scenario application: Widely used in food processing (conveying flour, powdered sugar), chemical industry (conveying powdered raw materials), building materials (conveying cement, gypsum) and pharmaceuticals (conveying medicinal powder) to achieve automated and precise material transmission.

Flexible screw conveyor for fine powder parameters

| Flexible conveyors models | 37 | 44 | 55 | 67 | 80 | 90 |

|---|---|---|---|---|---|---|

| Capacity in kg/h. | 100 | 400 | 800 | 2,000 | 5,000 | 7,000 |

| Minimum bending radius in meters* | 2 | 2.5 | 3 | 4 | 5.5 | 7. |

| Tube : int. Ø X ext. Ø in mm | 37 x 43 | 44 x 51 | 55 x 63 | 67 x 80 | 80 x 90 | 90 x 100 |

What is the working efficiency of the flexible screw conveyor for fine powder?

The working efficiency of the fine powder flexible screw conveyor is affected by many factors. The overall performance has a medium to high conveying efficiency, and has certain advantages in the adaptation scene.

The conveying efficiency is high for fine powders with good fluidity and dryness (such as flour, cement powder, and sugar powder). When the spiral rotates, it can quickly form a directional thrust, and the conveying capacity can reach 5~20 tons/hour (depending on the pipe diameter, rotation speed and material density). If the material is viscous and humid (such as wet clay powder and colloidal powder), it is easy to adhere to the spiral or the pipe wall, which may cause the conveying efficiency to drop by 30%~50%, or even cause blockage. It needs to be combined with pretreatment (such as drying) or reduce the rotation speed.

Horizontal or gentle bend conveying has the highest efficiency and can maintain a continuous and stable conveying state. It is suitable for production line layout that bypasses obstacles (such as multi-workshop powder transfer in food factories). Vertical or large-angle inclined conveying requires the thrust of the spiral to overcome gravity. The efficiency decreases as the angle increases, and it is easy to cause spiral wear. It is suitable for short-distance lifting (such as hopper loading in pharmaceutical factories).

What can the fine powder flexible screw conveyor be used for?

The flexible screw conveyor for fine powder is widely used in occasions where precise, closed and flexible conveying of powdered materials is required. It is suitable for food, chemical, plastic, pharmaceutical, building materials and other industries.

In the field of food processing, it is often used to transport fine powder raw materials such as flour, milk powder, starch, etc. from storage bins to mixing tanks or packaging machines; in the chemical industry, it can be used to transport dusty fine materials such as calcium carbonate, talcum powder, pigment powder, etc. to reactors or batching systems; in the plastics industry, it is used to transport PVC powder, masterbatch powder, etc. to the feed port of extrusion equipment; in pharmaceutical production, it can achieve clean transportation of drug powder and auxiliary materials and reduce manual contact; in the field of building materials, it can also be used to quantitatively transport putty powder and cement powder to automatic packaging lines or mixing systems. Its flexible structure is particularly suitable for sites with limited space and turning conveying paths, which can effectively improve material conveying efficiency and process automation level.

Price of flexible screw conveyor for fine powder

The price of fine powder flexible screw conveyor will vary according to different factors, including but not limited to equipment model, specifications (such as length, diameter, etc.), material (stainless steel or carbon steel, etc.), production capacity, additional functions, and whether it is customized.

|

Model |

Conveying capacity (t/h) |

Conveying length (m) |

Power (kW) |

Applicable material particle size |

|

LS100 |

0.5 - 2 |

3 - 10 |

1.1 - 3 |

≤5mm |

|

LS150 |

2 - 5 |

5 - 15 |

2.2 - 5.5 |

≤8mm |

|

LS200 |

5 - 10 |

6 - 20 |

3.0 - 7.5 |

≤10mm |

The price of small (pipe diameter Φ38~51mm, length 2~3 meters) is in the range of $600~$1,200; the price of medium (pipe diameter Φ63~76mm, length 3~5 meters) is in the range of $1,200~2,500; the price of large (pipe diameter Φ89~114mm, length more than 5 meters) is in the range of $2,500~$4,500+Equipment with automatic feeder or control system will be more expensive, between $3,000~ $6,000+ range.