Grain Moving Machine Augers

Tuesday April-22 2025 14:14:12

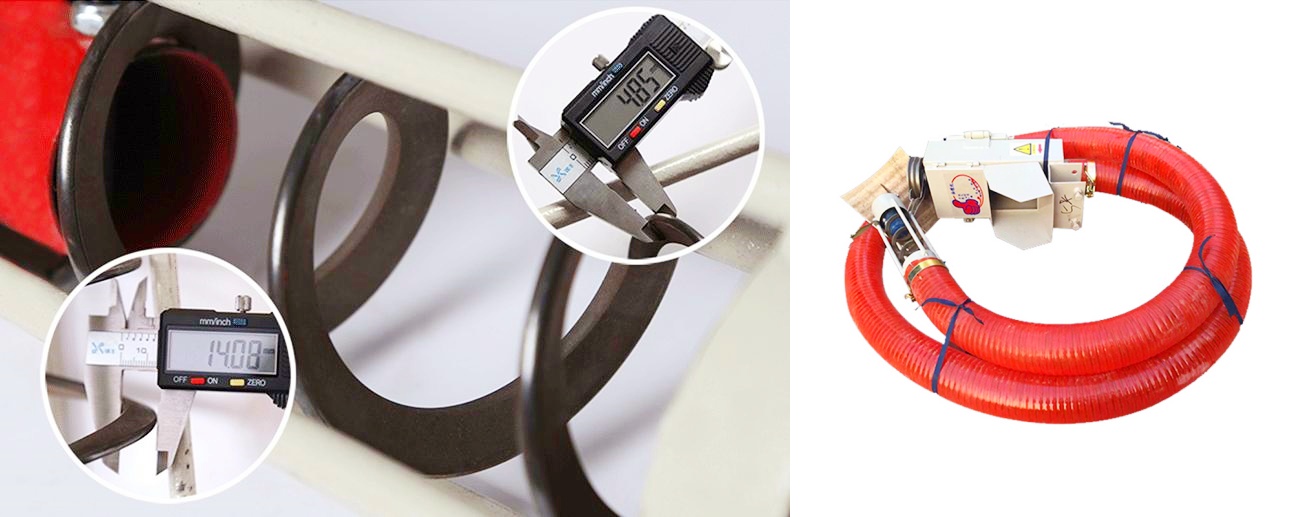

Grain moving machine augers are mechanical devices used in agriculture to efficiently move grain (corn, wheat, soybeans, or oats) from one location to another, such as from a truck to a storage bin or silo. They consist of a rotating spiral blade mounted within a cylindrical tube or trough. The rotation of the spiral blades moves the grain along the length of the auger, which can be horizontal, inclined, or vertical. This design ensures continuous, controlled delivery of grain with minimal spillage, making it a cornerstone of agricultural logistics, grain storage, and processing facilities.

Grain Moving Machine Augers video

Applicable materials for Grain Moving Machine Augers

Grain moving machine augers is one of the most commonly used continuous conveying equipment in agriculture and industry, suitable for a variety of dry, fluid granular and powdery materials.

Bulk grains: wheat (moisture content ≤ 14%), corn (whole or broken), rice (brown/polished/broken), barley/oats/rye

Pulse crops: soybeans (whole beans), mung/red/kidney beans, chickpeas/lentils

Oil crops and by-products: oilseeds, rapeseed (diameter 1.5-2mm), sunflower seeds (shelled/shelled), cottonseed/flaxseed

Energy feed: corn meal (adjustable coarseness), wheat bran, rice bran

Protein feed: fish meal (preservative design required), meat and bone meal, yeast powder

|

Type |

Recommended material examples |

Special recommendations |

|

Cereals |

Wheat, corn, soybeans |

Speed control, damage prevention |

|

Feed |

Premix, pellet feed |

Sealed moisture-proof, low speed |

|

Food |

Flour, coffee beans, bean powder |

Food grade material, low speed |

|

Industrial materials |

Wood chips, plastic particles, urea |

Anti-corrosion, anti-static |

What are the advantages of Grain Moving Machine Augers?

Handling grain flow inconsistencies and blockages: Grain flow may stop or slow down due to agglomeration, uneven loading or narrow chute - especially wet or sticky grains. The screw rotation ensures smooth and continuous feeding.

Addressing grain breakage and damage: Grains such as corn, wheat or barley can break or crack during high-speed or high-impact transport. Slow-speed rotation and soft-start motors minimize shock. Gentle pitch angles and controlled pitch spiral blades reduce shear forces.

Reducing moisture and mold buildup: Moisture buildup in transport pipes can cause grain spoilage, mold and fermentation, especially in humid environments. Sealed or closed auger housings protect grain from external moisture.

Avoiding cross-contamination between grain types: Switching between different types of grain (e.g. wheat → soybeans) in the same transport system can cause contamination. Segments can be easily changed using the modular Grain Moving Machine Augers system.

Mesh recommendation of Grain Moving Machine Augers

|

Grain type |

Application scenario |

Recommended mesh range |

Description |

|

Wheat |

Cleaning impurities, discharging control |

6-12 mesh |

Filtering larger foreign matter, such as wheat husks and stones |

|

Corn |

Classification before crushing, screening before loading |

2-6 mesh |

Corn particles are large, requiring large holes |

|

Soybeans |

Cleaning before storage |

4-8 mesh |

Filtering broken grains and pods |

|

Rice |

Removal of impurities and pre-cleaning before storage |

6-10 mesh |

Removal of weed seeds, insect eggs and other small impurities |

|

Sorghum |

Feed pretreatment |

8-14 mesh |

Separation of small particle impurities |

|

Malt |

Used in breweries to prevent damage |

≥10 mesh |

High requirements for the protection of intact particles |

Application and application scenarios of Grain Moving Machine Augers

Grain moving machine augers are versatile tools widely used in the agricultural supply chain. Its main function is to transport grain quickly and safely, reduce labor and prevent grain deterioration or contamination.

Harvesting and transfer from field to truck: During harvest, a combine harvester collects grains such as wheat or corn into a hopper. Grain moving machine augers are used to transfer grain from the combine harvester to a grain car or truck for transport to a warehouse.

Temporary storage and transportation after harvesting: After farmers harvest corn, wheat and other grains with a combine harvester in the field, they need to transfer the grain from the harvester to a transport car or temporary grain storage box. Grain moving machine augers quickly transfer grain, improving efficiency and reducing manual handling.

Storage loading and unloading system: Grain is stored in large grain storage silos, and loading and unloading needs to be efficient and systematic. Use a long-distance, tilted fixed screw conveyor to transport grain from the ground to the high-level silo; a horizontal screw conveyor installed at the bottom evenly pushes the grain out of the silo to the next equipment or vehicle.

Grain transportation before and after drying: Grain needs to be dried to extend its storage life. Grain is transported from the initial storage point to the dryer through a short-distance grain moving machine augers, and then transported to the storage silo or processing line after drying.

Grain moving machine augers are essential tools in agricultural and industrial settings, enabling efficient and controlled conveying of bulk grain. Their design must take into account the size, shape and flow characteristics of the grain to prevent blockages and ensure smooth operation, with versatility and portability to ensure seamless integration into warehousing and processing workflows.