Grain Processing Z-type Bucket Elevator

Saturday June-07 2025 16:48:12

What is Grain Processing Z-type Bucket Elevator

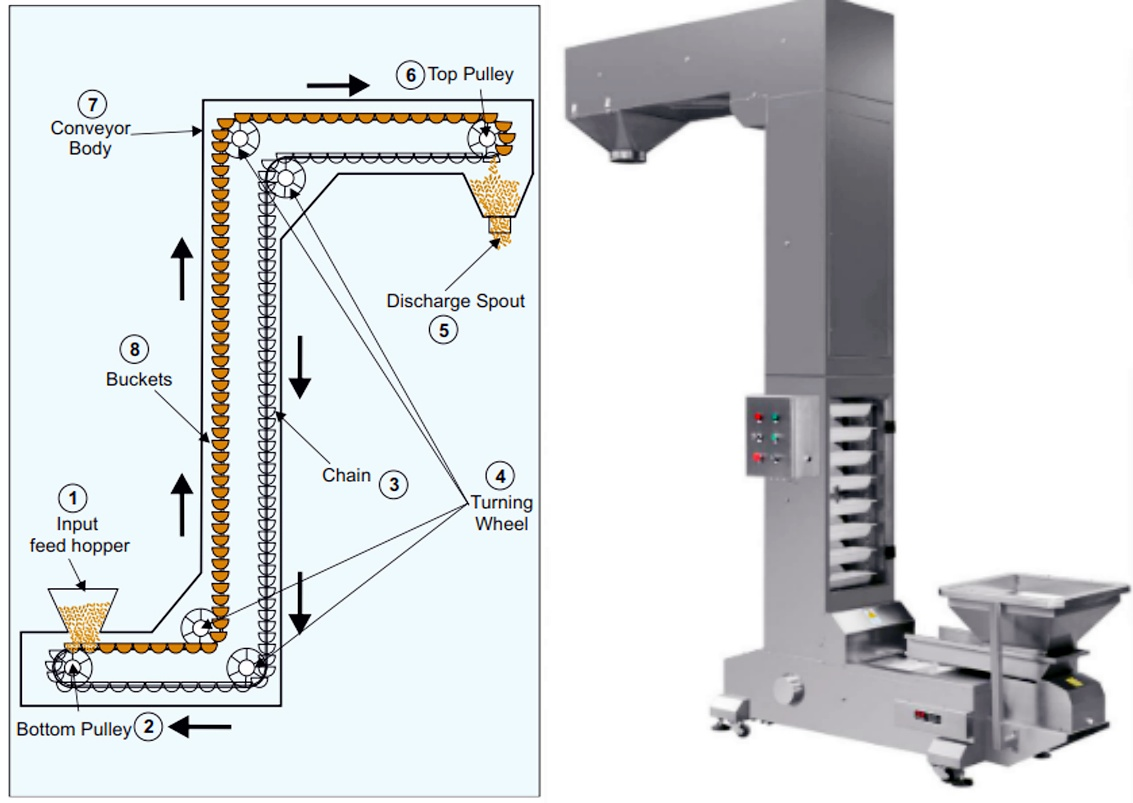

Grain processing z-type bucket elevator is a slow-speed lifting equipment designed for grain granular materials (such as rice, corn, wheat, beans, etc.), suitable for processing processes with strict control of material breakage rate and high cleanliness requirements.

The equipment adopts a closed conveying structure, and the chain pulls the bucket along the "horizontal-vertical-horizontal" Z-type path to achieve smooth lifting of materials from low positions to high designated positions for unloading. Compared with traditional vertical bucket elevators, Z-type elevators have smooth operation, low noise, and small impact on materials, which can significantly reduce grain breakage and mixing problems. At the same time, its closed design can effectively prevent dust leakage and cross contamination.

This equipment is often used for temporary storage, metering and lifting of materials after cleaning and connection with packaging lines. It has a gentle lifting effect and high conveying efficiency. It is an important auxiliary equipment for modern grain processing enterprises to achieve automated production.

What is the difference between a Z-type bucket elevator and a bucket conveyor for grain processing?

The Z-type bucket elevator is driven by a motor to drive the bucket to run in a closed "Z"-shaped track. After the material enters the bucket through the feed port, it runs to the top with the chain and is unloaded by gravity or mechanical means. Suitable for gentle conveying and controlling the breakage rate. The material of the vertical bucket conveyor enters the high-speed running bucket from the bottom, and the bucket is vertically brought to the top by the traction component and unloaded by centrifugal force or gravity. Suitable for large flow and continuous vertical transportation.

|

Project |

Z-type bucket elevator |

Bucket conveyor (generally refers to vertical bucket elevator) |

|

Picture |

|

|

|

Basic definition |

A lifting equipment that guides the bucket to run on the "horizontal-vertical-horizontal" path with a closed track |

Mainly used for conveying equipment that continuously lifts granular or powdered materials in the vertical direction |

|

Project |

Z-type bucket elevator |

Vertical bucket conveyor |

|

Conveying direction |

Horizontal + vertical combination |

Mainly vertical, some can be inclined |

|

Feeding and discharging method |

Horizontal feeding, top gravity discharging (multi-point feeding/discharging) |

Bottom vertical feeding, top gravity discharging |

|

Conveying capacity |

Suitable for small and medium-sized production |

Wide range of production, from a few tons to hundreds of tons per hour |

|

Applicable materials |

Fragile, low-breakage granular materials (such as grain, seeds, food granules) |

Powdered, granular, large quantities of materials (such as cement, coal powder, grain raw materials) |

How does the grain processing Z-type bucket elevator work?

The working process of the grain processing Z-type bucket elevator mainly relies on the chain to pull the bucket to complete the horizontal transportation, vertical lifting and unloading of materials in the closed "Z"-shaped track.

① Feeding stage: Grain materials enter the hopper evenly through the feeding port of the horizontal section. The feeding method is generally vibrating feeding or belt conveying to ensure stable loading of the hopper and avoid spilling or blockage.

② Conveying stage: The motor drives the sprocket to make the chain run along the guide rail, driving the hopper to move along the set path ("horizontal → vertical → horizontal"). The entire conveying process runs slowly and steadily, and there is a gap between the hoppers to avoid material accumulation or extrusion.

③ Lifting stage: The material moves vertically upward with the hopper, and is not squeezed by external force during this process, which can effectively maintain the integrity of the grain particles and reduce damage.

④ Unloading stage: When the hopper runs to the discharge port of the top horizontal section, the unloading door is usually opened by gravity or a mechanical push rod, and the material is automatically dumped into downstream equipment, such as packaging machines, screening machines or storage silos.

⑤ Return stage: The empty hopper continues to run along the track and returns to the bottom to be reloaded, forming a continuous cycle.

The entire working process is carried out in a closed shell, which prevents dust from leaking out and external impurities from entering. It is suitable for grain processing scenarios that require hygiene and low breakage rate.

What are the disadvantages of the Z-type bucket elevator for grain processing?

The structure is relatively complex, especially the design of the Z-shaped path makes the installation and commissioning of the equipment cumbersome, and requires high site layout and equipment accuracy. Secondly, since the chain or belt is used to drive the hopper to circulate, it is easy to generate certain vibrations and noise during operation, affecting the comfort of the working environment. In addition, the equipment has certain restrictions on the adaptability of materials. For grain raw materials with high moisture content, strong viscosity or easy to agglomerate, it is easy to cause blockage or incomplete unloading, affecting the conveying efficiency.

What is the conveying capacity of the Z-type bucket elevator for grain processing?

The conveying capacity of the Z-type bucket elevator for grain processing is affected by factors such as hopper specifications, lifting speed, grain type (density), and filling coefficient. Equipment of different models and configurations varies greatly.

|

Model/Specification |

Hopper Volume (L/pcs) |

Lifting Speed(m/s) |

Conveying Capacity (t/h) |

Applicable Scenarios |

|

Small (Z10-Z20) |

5-20 |

0.5-1.0 |

5-20 |

Small grain depot, laboratory processing line |

|

Medium (Z30-Z50) |

30-80 |

1.0-1.5 |

20-80 |

Medium flour mill, rice mill |

|

Large (Z60+) |

100-300+ |

1.5-2.0 |

80-300+ |

Large grain processing plant, port storage |

What can Z-type bucket elevator be used for in the field of grain processing

Z-type bucket elevator is mainly used for flexible lifting and quantitative conveying of granular materials (such as rice, wheat, corn, beans, etc.) in the field of grain processing, and is widely used in process links such as cleaning, packaging, weighing, and batching. Its closed structure effectively prevents dust leakage and material contamination, and is suitable for process flows with high requirements for hygiene and breakage rate. The equipment uses a chain to pull the hopper along the "horizontal-vertical-horizontal" path to achieve fixed-point lifting and smooth unloading of materials. It is particularly suitable for use with automatic packaging machines, weighing systems and other equipment, which can improve the automation level of the production line, improve transportation efficiency and maintain material integrity.

The grain processing Z-type bucket elevator plays an important role in the grain processing industry with its compact structure, flexible layout and efficient transportation capacity, ensuring the smooth and efficient production process. It not only improves production efficiency, but also reduces labor intensity. It is one of the key equipment in modern grain processing production lines. If you need more specific information, such as equipment manufacturer, model, technical parameters or quotation, it is recommended that you provide more detailed requirements so that I can provide you with more accurate help.