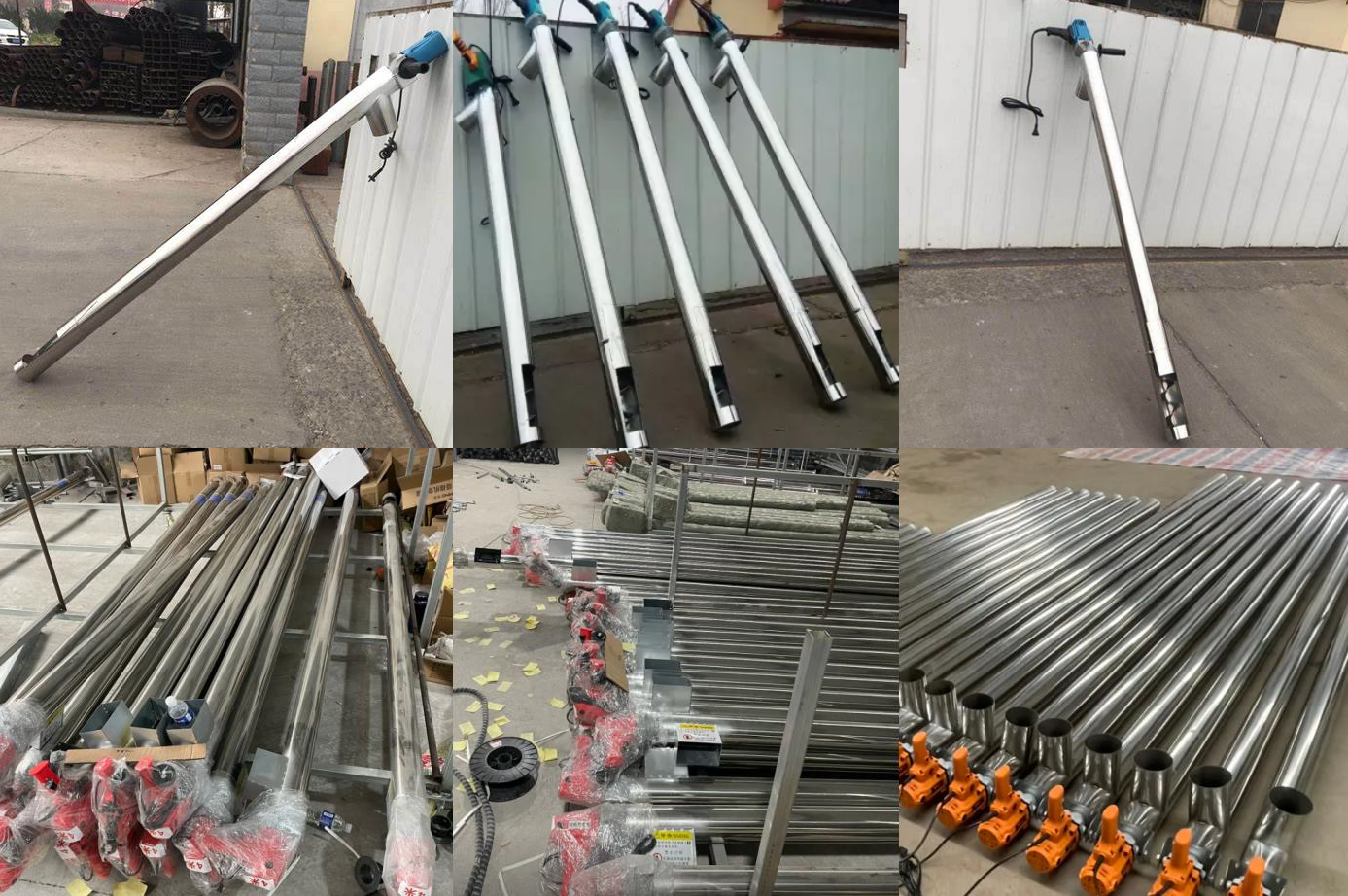

Handheld Stainless Steel Grain Collector Machine

Friday May-16 2025 16:23:24

The handheld stainless steel grain collector machine is a small, portable material conveying equipment, mainly used for grain loading and unloading operations in agriculture, grain processing or storage, etc. It is mainly used to efficiently and dust-freely absorb and transfer grains and granular materials (such as wheat, corn, soybeans, feed, etc.). It uses the principle of spiral conveying to quickly suck and transport bulk grains (such as wheat, corn, rice, etc.) from the ground or container to the designated location, and is widely used in agricultural harvesting, grain storage management and other links.

Applicable materials for handheld stainless steel grain collector machine

Handheld stainless steel grain collector machine is suitable for a variety of dry, fluid granular or powdered materials, especially in agriculture, food processing and storage. The following are its main applicable materials:

Powdered materials: flour, starch, feed powder, etc.

Beans: soybeans, mung beans, red beans, peanuts, coffee beans, etc.

Seeds: vegetable seeds, grass seeds, crop seeds, etc.

Grains: wheat, corn, rice, paddy, barley, oats, sorghum, etc., suitable for the absorption and transportation of various grains

Other granular materials: granular feed, fertilizer granules, plastic granules, etc., some small dried fruits (such as walnuts, hazelnuts) can also be applied

Working principle of handheld stainless steel grain collector machine

① Power drive: The suction machine is usually equipped with an electric motor or a small fuel engine as a power source to drive the internal fan or vacuum pump to operate.

② Generate negative pressure: The fan rotates at high speed, forming a low-pressure area (negative pressure) in the pipe system of the grain suction machine.

③ Material suction and separation: Grains enter the conveying pipeline through the suction nozzle with the air flow. The motor drives the suction fan to generate negative pressure, suck up bulk grains, grains, beans and other materials, and transport them to the target container through a hose or a rigid pipe. The grain suction machine has a compact structure and can effectively avoid damage to grains during transportation.

④ Transportation and discharge: The sucked grains can be directly transported to the designated location (such as grain storage bins, bags or transportation tools) through pipes. Some grain suction machines are equipped with screw conveying devices or pneumatic push systems to further assist in the directional transportation of materials.

Features of stainless steel materials: The machine is made of stainless steel, which is corrosion-resistant, wear-resistant and easy to clean. It is suitable for food-grade material processing and ensures that the grains are pollution-free.

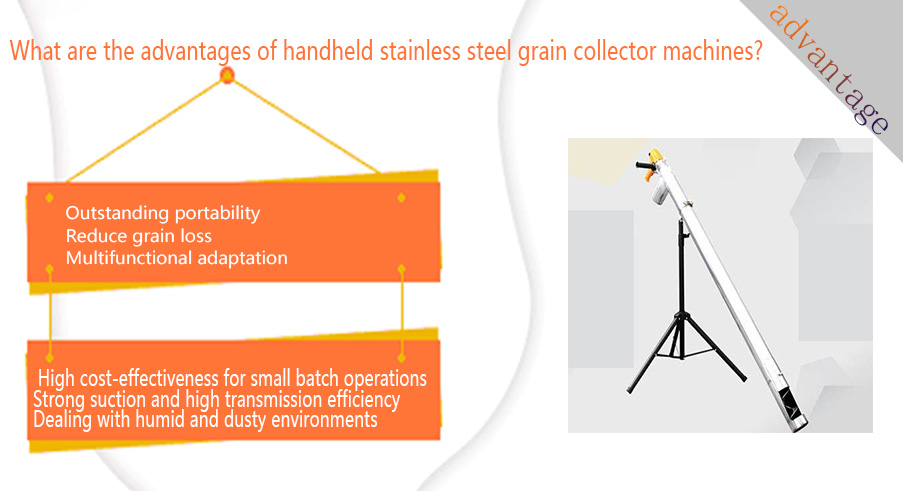

What are the advantages of handheld stainless steel grain collector machines?

Outstanding portability: Handheld design, the weight of the whole machine is usually 5-10 kg, and it can be easily operated by one person, suitable for narrow spaces (such as small granaries and agricultural carriages).

Reduce grain loss: Pipeline transmission avoids grain spillage, which can reduce losses by 5%-10% compared to traditional manual handling, and is especially suitable for high-value crops (such as soybeans and peanuts).

Multifunctional adaptation: It can adapt to various granular grains such as wheat, corn, and rice by replacing suction nozzles or hoses of different specifications, and has strong versatility.

High cost-effectiveness for small batch operations: Compared with large vehicle-mounted grain suction machines, handheld stainless steel grain collector machine has low purchase costs, is suitable for small-scale grain production or temporary transportation needs, and has a high input-output ratio.

Strong suction and high transmission efficiency: Equipped with a high-power motor, it generates strong suction and can quickly suck grain from the ground, grain piles, etc. into the pipeline, and the transmission speed can usually reach 3-5 tons/hour. The detachable structure is easy to store and transport, especially suitable for scenarios such as family farms and individual grain traders that require mobile operations.

Dealing with humid and dusty environments: The sealed pipeline design can reduce the contact between grain and the outside world, prevent the grain from being damp due to humid weather, and reduce dust flying, improving the working environment. It is suitable for rainy days, emergency transportation and other scenarios, and quickly completes the grain storage.

Application scope of handheld stainless steel grain collector machine

Handheld stainless steel grain collector machine is mainly used in occasions such as conveying, loading and unloading and cleaning of grain or similar granular materials that require small amounts, short distances and flexible movement.

① Grain procurement and loading and unloading operations: Handheld grain suction machines are widely used in grain procurement points, grain stations, grain depots and other places to quickly suck bulk wheat, corn, rice, sorghum, soybeans and other grains into warehouses or transfer vehicles. Compared with traditional manual handling methods, this equipment has high efficiency and low labor intensity, and is especially suitable for small and medium-sized grain operators or mobile grain collectors.

② Farmers' household grain storage and transportation: In rural families, handheld stainless steel grain collector machines can be used for grain transportation in their own courtyards or small granaries, such as sucking grain from ground piles into grain storage silos, pouring from woven bags into barrel silos, etc. The equipment is small and light, suitable for individual or family users to operate, and meets the needs of small and multiple handling.

③ Material transportation in feed processing plants: In small feed plants, farms and other places, handheld gstainless steel grain collector machines can be used to transport feed raw materials such as corn, soybeans, and wheat, which helps to quickly transport raw materials from bagged state to crushers, mixers or storage bins, improve feeding efficiency, and reduce manual feeding operations.

④ Used in seed processing and packaging places: When seed companies or breeding bases are grading and packaging seeds, handheld grain suckers can realize quantitative seed transportation and packaging operations. The equipment can be used to process a variety of seeds such as rice, wheat, corn, etc., and the stainless steel material reduces friction and pollution on the seed surface.

Farms, grain depots, grain processing plants and other places

Absorbing granular materials such as rice, wheat, corn, beans, etc.

Grain loading, unloading, transfer and storage

Precautions for handheld stainless steel grain collector machines

Operation precautions: Before use, check whether the motor, power cord, hose and connecting parts are intact, without damage or looseness. Ensure that there is no foreign matter blocking the grain sucker pipeline to avoid affecting the conveying efficiency or damaging the equipment.

① Correct operation: Keep the hose straight during operation, avoid excessive bending or winding, so as not to reduce suction or damage the hose. When sucking grain, slowly insert it into the grain pile, control the feeding speed, and prevent excessive materials from clogging the pipeline. Avoid long-term continuous operation to prevent the motor from overheating.

② Applicable materials: Only used to transport dry, granular materials (such as wheat, corn, soybeans, etc.), avoid sucking wet grain, sticky materials or large pieces of debris. If conveying non-grain materials (such as plastic particles), confirm the applicability of the equipment to avoid wearing the pipe or motor.

Safety precautions: Avoid hands or clothing near the suction port to prevent being sucked in or entangled. Operate in a well-ventilated environment to reduce dust accumulation and cause fire or respiratory problems.

① Emergency: If the equipment is abnormal (such as abnormal sound, vibration or sudden drop in suction), stop and check immediately, and do not use it forcibly. Equip a fire extinguisher just in case, especially when used in dry grain silos.

② Maintenance and care: Clean the residual materials in the pipeline and suction port after each use to prevent mildew or blockage. Clean stainless steel parts regularly to keep the surface free of corrosion and extend the service life.

③Inspection and lubrication: Check the motor bearings and transmission parts regularly, and add lubricating oil if necessary to reduce wear. Check the wear of the hose. If the wear-resistant tendon hose or stainless steel spiral tube is damaged, it should be replaced in time.

Ensure the safe and efficient operation of the handheld stainless steel grain collector machine, while extending the service life of the equipment. If you need a maintenance manual for a specific model or further suggestions, please provide the required length, power, conveying capacity, applicable materials, etc. of the equipment, and we can help you provide more information and prices!