Hose Auger Feeder for Truck Unloading and Loading Wood Chips

Thursday May-15 2025 17:24:00

The hose auger feeder for truck unloading and loading wood chips is a bulk conveying equipment designed for the light and dusty characteristics of wood chips. Its flexible hose can be flexibly bent to adapt to the height and angle of the truck cargo box to achieve rapid unloading or loading of wood chips. The spiral blades are made of wear-resistant material to effectively deal with the friction of wood chip fibers, and the fully sealed structure prevents dust from spilling.

The equipment supports mobile installation, and can adjust the conveying angle and length to meet the needs of different models and sites. With variable frequency drive, it can accurately control the flow rate, avoid wood chips from clogging or splashing, and significantly improve the efficiency of truck loading and unloading. It is an efficient solution in the fields of wood processing, biomass energy, etc.

Scope and limitations of hose auger feeder for truck unloading and loading wood chips

Scope of application:

① Truck unloading wood chips (ground wood chips are transported to the carriage)

② Truck loading wood chips (carriage wood chips are transported to the storage area or container)

③ Temporary transfer of various lightweight materials, such as rice husks, sawdust, husks, plastic particles, etc.

Limitations: Not suitable for conveying high-temperature materials (such as hot wood chips); long-distance and large-angle conveying efficiency is limited, and the recommended length is controlled within 15 meters; flexible structure is not suitable for conveying large block materials or hard materials

Working principle of hose auger feeder for truck unloading and loading wood chips

The hose auger feeder for truck unloading and loading wood chips is mainly composed of a drive motor, a hose housing, a spiral steel belt (shaftless spiral), a feed port, a discharge port, connectors and a support frame. Its working principle is similar to that of ordinary screw conveyors: the motor drives the spiral steel belt to rotate, and the material moves forward along the hose under the action of the spiral propulsion force and gravity, thus completing the conveying process.

The hose part mostly uses PVC reinforced hose or PU hose, which is both flexible and wear-resistant. The internal spiral body is usually a high-strength spring steel or manganese steel flat belt to achieve flexible drive and long-distance transportation.

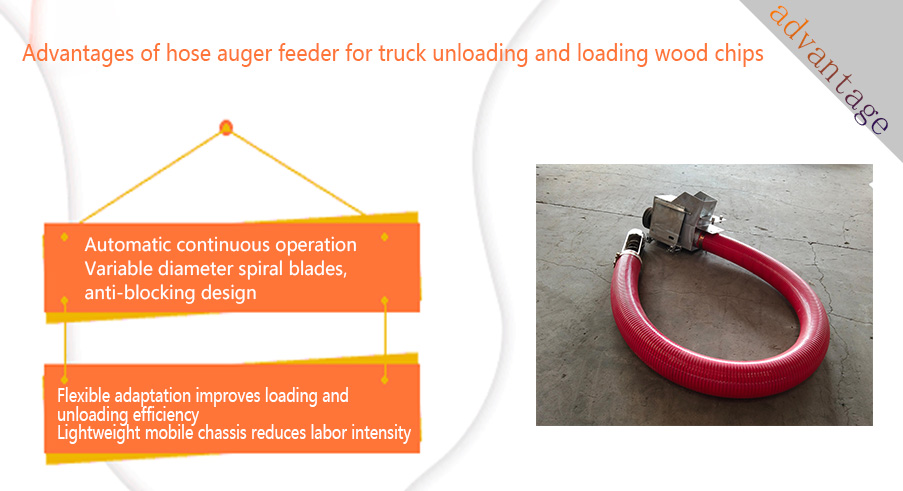

Advantages of hose auger feeder for truck unloading and loading wood chips

Automatic continuous operation: The standard variable frequency motor (power 7.5-15kW) can adjust the screw speed (50-200rpm) in real time according to the humidity and particle size of the wood chips. The maximum conveying capacity is 25m³/h. A single device can replace 5-8 loading and unloading workers, reducing labor costs by more than 60%.

Variable diameter spiral blades, anti-blocking design: In view of the characteristics of wood chips that are easy to agglomerate or entangle, the spiral blade adopts a variable diameter and variable pitch structure, the front end is loosely designed to prevent large pieces of material from getting stuck, and the rear end has encrypted teeth to enhance the crushing ability. The frequency conversion motor dynamically adjusts the speed to ensure continuous and stable transportation.

Flexible adaptation improves loading and unloading efficiency: The equipment hose can be bent 180° to adapt to truck cargo boxes of different heights. The hydraulic lifting device can accurately dock the discharge port to reduce the time of manual material leveling. The loading capacity of a single device can reach 30-50 cubic meters per hour, which is 5-8 times the efficiency of manual labor.

Lightweight mobile chassis reduces labor intensity: The whole machine integrates universal wheels and traction handles, and a single person can push it to any operating point, avoiding the cumbersome process of hoisting and adjustment of traditional conveyors. It is especially suitable for small and medium-sized enterprises with multiple models and multiple workstations.

Technical specifications of hose auger feeder for truck unloading and loading wood chips

|

Tube diameter |

length |

voltage |

power |

efficiency |

weight |

|

100mm |

3m |

220V |

3KW |

5-6 tons |

43kg |

|

100mm |

4m |

220V |

3KW |

5-6 tons |

47kg |

|

100mm |

5m |

220V |

3KW |

5-6 tons |

51kg |

|

100mm |

6m |

220V |

3KW |

5-6 tons |

55kg |

|

100mm |

7m |

220V |

3KW |

5-6 tons |

62kg |

|

100mm |

8m |

220V |

3KW |

5-6 Ton |

66kg |

|

100mm |

9m |

220V |

3KW |

5-6t |

70kg |

|

100mm |

10m |

220V |

4KW |

5-6t |

74kg |

|

100mm |

11m |

380V |

4KW |

5-6t |

82kg |

|

100mm |

12m |

380V |

4KW |

5-6t |

86kg |

|

120mm |

3m |

220V |

3KW |

7-8t |

48kg |

|

120mm |

4m |

220V |

3KW |

7-8t |

52kg |

|

120mm |

5m |

220V |

3KW |

7-8t |

56kg |

|

120mm |

6m |

220V |

3KW |

7-8 tons |

60kg |

|

120mm |

7m |

220V |

4KW |

7-8 tons |

60kg |

|

120mm |

8m |

220V |

4KW |

7-8 tons |

71kg |

|

120mm |

9m |

220V |

4KW |

7-8 tons |

75kg |

|

120mm |

10m |

220V |

4KW |

7-8 tons |

79kg |

|

120mm |

11m |

380V |

4KW |

7-8 tons |

89kg |

|

120mm |

12m |

380V |

4KW |

7-8 tons |

93kg |

|

100mm |

2 0m |

380V |

7.5KW |

5-6t |

150kg |

|

100mm |

25m |

380V |

7.5KW |

5-6t |

170kg |

|

120mm |

20m |

380V |

7.5KW |

6-7t |

180kg |

|

120mm |

22m |

380V |

7.5KW |

6-7t |

200kg |

Application of hose auger feeder for truck unloading and loading wood chips

Wood processing plant: Wood chips generated by sawing and planing need to be quickly transferred to trucks. Through the hose auger feeder for truck unloading and loading wood chips, it penetrates into the bottom or side of the truck compartment, and the spiral blades move the wood chips from the ground or storage bin at a constant speed.

The equipment is equipped with a mobile bracket, which can adjust the angle according to the position of the truck to achieve continuous feeding, and the single loading efficiency is increased by more than 50%, avoiding the risk of slipping caused by the slippery ground of traditional loaders, and reducing the loss of sawdust caused by mechanical crushing.

Furniture factory waste recycling: scrap sawdust needs to be shipped out regularly, and the conveyor seal design prevents fiber drifting, adapts to trucks of different tonnages, shortens vehicle detention time, and optimizes logistics turnover.

Paper mill raw material transportation: sawdust as pulp raw material needs to be kept dry, the spiral structure of the equipment can break up slight lumps, and the loading volume can be accurately controlled with frequency conversion speed regulation to avoid spillage during transportation. The equipment has become a sawdust production base through flexible adaptation, dust-proof transportation, and efficient loading. Key equipment for truck loading and unloading in the industry chain.

Typical case comparison

|

Scenario |

Traditional loader solution |

Hose auger feeder for truck unloading and loading wood chips |

|

Handling and unloading of wet wood chips |

Buckets are easy to stick to materials and need to be cleaned frequently |

Hose inner wall is smooth, screw thrust is strong, and does not stick to materials |

|

Dust-sensitive areas |

Additional dust removal equipment is required, which increases costs |

Fully enclosed transportation, no additional dust removal required |

In view of the characteristics of wood chips that are light, fluffy and easy to generate dust, the enclosed hose design of the hose auger feeder for truck unloading and loading wood chips can effectively reduce the flying and scattering of wood chips during transportation, keep the environment clean, and reduce material loss. The flexibility of its hose enables it to easily adjust the conveying path to adapt to the different positions of the truck discharge port and the silo interface, simplify unloading and loading operations, and improve efficiency. This screw conveyor has a compact structure, is easy to move and deploy, and is an ideal choice for truck wood chip loading and unloading.