Hose Type Screw Conveyor For Dry

Saturday May-10 2025 18:21:18

What is a hose type screw conveyor for dry?

Hose type screw conveyor for dry is a transmission specially used for conveying dry, powdery or granular materials. It combines the cooperation of hoses (flexible pipes) and spiral blades to realize the conveying of materials, and is suitable for use in scenes with complex layouts or limited space. Compared with traditional fixed screw conveyors, hose type screw conveyors for dry have greater flexibility and can convey materials in limited spaces, especially suitable for installation environments with curves or narrow spaces.

Scope of application

Conveying powder and granular materials, such as fertilizers, plastic particles, flour, sand, etc.

Conveying dry materials is not suitable for conveying materials with high humidity or viscosity.

It is especially suitable for occasions where conveying is required in limited space, such as production workshops, storage areas, etc.

What is the working principle of hose type screw conveyor for dry?

①Screw push principle: The motor drives the screw shaft to rotate, and the spiral blade pushes the material to move along the axial direction of the screw shaft in the hose, thereby realizing the conveying of materials. Just like a rotating propeller pushes the material forward in the pipeline.

②Gravity auxiliary effect: In the process of material conveying, gravity also plays a certain auxiliary role, helping the material to flow downward more smoothly under the push of the spiral blade, especially when conveying at an angle or vertically, gravity can reduce the resistance of the screw shaft to push the material.

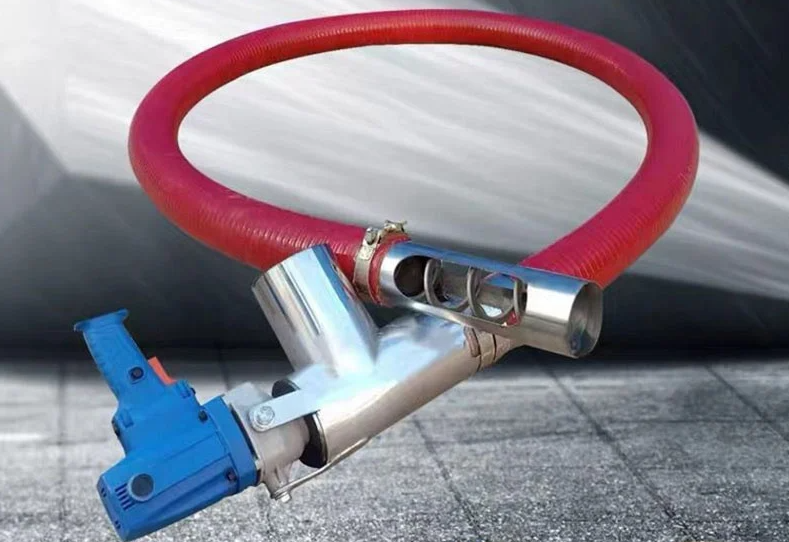

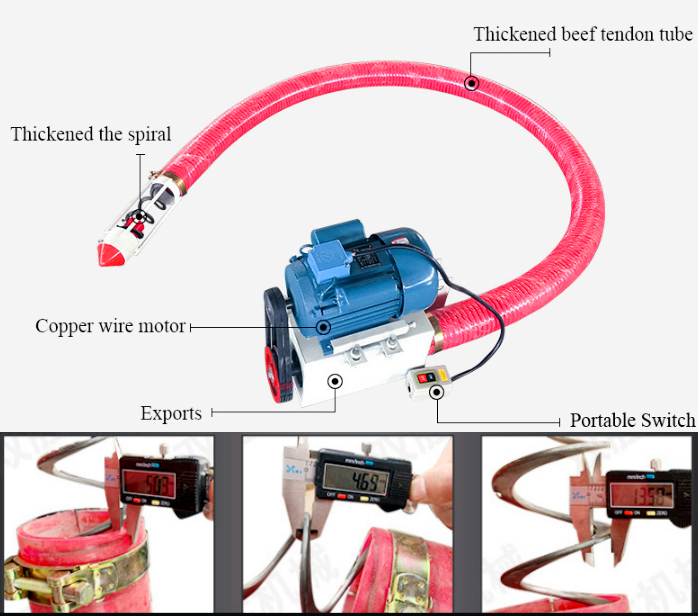

Structural composition of hose type screw conveyor for dry

Drive device: usually composed of a motor, a reducer, a coupling, etc., to provide power for the rotation of the screw shaft, so that the screw shaft can rotate at a suitable speed.

Screw shaft and spiral blade: The screw shaft is the core component of the conveyor. The spiral blade is fixed on the screw shaft, and the material is pushed forward as the screw shaft rotates.

Hose: It is generally made of wear-resistant and corrosion-resistant rubber or plastic materials, which can adapt to different conveying environments and conveying routes, and prevent material leakage.

Feed port and discharge port: The feed port is used to introduce materials into the conveyor, and the discharge port is used to transport materials to the designated location.

Comparison between hose type screw conveyor for dry and traditional screw conveyor

|

Comparison items |

Hose type screw conveyor for dry |

Traditional screw conveyor |

|

picture |

|

|

|

Structure |

Flexible hose, bendable |

Rigid metal trough, fixed structure |

|

Transport flexibility |

High, can be detoured and bent, adapt to complex layout or space-constrained environment |

Low, requires straight or fixed path, suitable for large production lines or fixed equipment |

|

Anti-blocking ability |

Shaftless design has strong anti-winding/blocking ability, suitable for lime powder and other easy-to-agglomerate materials |

Shaft design is easy to block for sticky or agglomerated materials |

|

Applicable materials |

Dry powder/granules (such as lime powder, fly ash, cement), suitable for non-sticky or low-sticky materials |

Dry or wet materials (lime powder, sand, grain, etc.), easy to block for sticky materials |

|

Size and scale |

Small/mini models are common, suitable for small batch conveying (diameter 100-200mm, length 2-20m) |

Mostly medium and large designs (diameter 100-800mm, length up to 70m), suitable for large batch conveying |

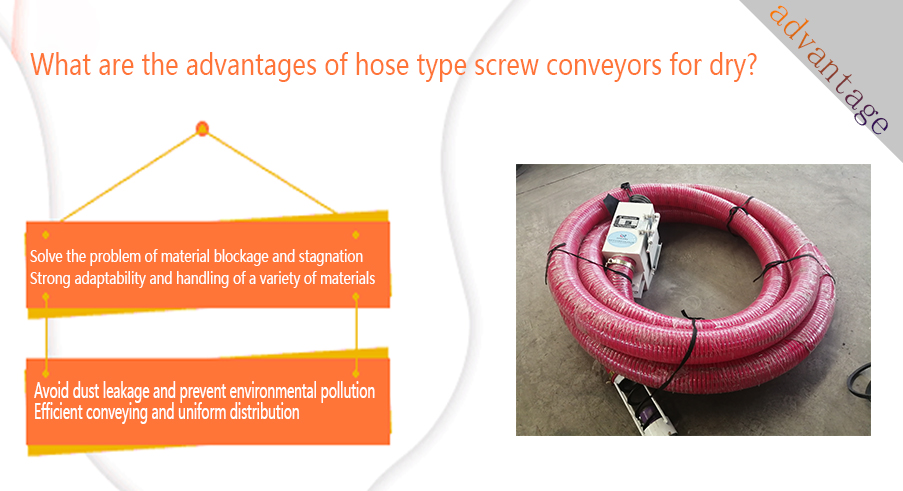

What are the advantages of hose type screw conveyors for dry?

1. Solve the problem of material blockage and stagnation: The design of the hose type screw conveyor for dry takes into account the fluidity of the material, especially for those materials that are prone to blockage (such as powders, particles, etc.). The spiral blades in the hose can ensure that the material will not be stuck during the conveying process. The flexible characteristics of the hose also help to reduce the resistance caused by material accumulation or irregular flow.

2. Strong adaptability and handling of a variety of materials: The combination of the spiral blades and the hose type screw conveyor for dry can adapt to the conveying of materials of different properties. It can handle a variety of materials from powders to particles, avoiding the complication of equipment design caused by the variety of materials. For example, when handling dry powders, particles or small pieces of materials, efficient conveying can be ensured by adjusting the rigidity of the hose or the design of the spiral blades.

3. Avoid dust leakage and prevent environmental pollution: For hose type screw conveyor for dry, the hose structure can not only prevent the leakage of materials during the conveying process, but also effectively control the generation and diffusion of dust. Through the design of the sealing system, hose type screw conveyor for dry can reduce the dust content in the air, thereby protecting the working environment.

4. Efficient conveying and uniform distribution: The spiral blades of hose type screw conveyor for dry have high conveying efficiency and can evenly convey materials to the predetermined location. This is crucial for the continuity and efficiency of the production line, especially in application scenarios where materials need to be conveyed continuously for a long time. Uniform material flow also helps to improve overall production efficiency.

Application of hose type screw conveyor for dry

Additive delivery: In the production of chemical products, it is often necessary to add various small amounts of additives, such as catalysts, pigments, antioxidants, etc. The hose type screw conveyor for dry can accurately control the delivery amount of additives to ensure uniform mixing of additives and main materials, thereby improving product quality.

Grain delivery: For the delivery of grains such as rice, wheat, and corn, the hose type screw conveyor for dry can transport grains from the warehouse to processing equipment, such as rice mills, mills, etc., without causing damage to the grains during the delivery process, ensuring the integrity and quality of the grains.

Cement delivery: In cement plants, hose type screw conveyor for dry can transport cement from the cement kiln to the cement warehouse, and then from the cement warehouse to the packaging machine for packaging, or to the concrete mixing station for concrete production. The screw conveyor can adapt to the characteristics of cement and is not easy to get blocked during the conveying process, ensuring the smooth production and supply of cement.

Feed conveying: The conveyor is used to convey various feed raw materials, such as corn meal, soybean meal, fish meal, etc., to the mixer for mixing to make compound feed. It can accurately control the conveying amount of various raw materials according to the requirements of the feed formula. In farms, screw conveyors are also often used to transport feed from the feed storage area to various breeding pens.

Hose type screw conveyor for dry is suitable for a variety of conveying occasions that require dry materials. It has the characteristics of simple structure, strong adaptability, and easy operation and maintenance. Because of its flexible conveying pipeline, it can effectively avoid material loss and pollution, so it has been widely used in many industries.