Hose conveyor for corn

Thursday June-12 2025 16:50:55

Corn grains are full, hard, and fluid, so excessive crushing should be avoided during transportation. The corn hose conveyor is an efficient conveying equipment designed for this purpose. It uses wear-resistant tendon hose and spiral spring structure, which can effectively reduce the breakage rate of corn during transportation, generally controlled at around 0.2%. Common models include pipe diameters of 75mm, 100mm and 125mm, which are suitable for medium and short-distance horizontal or inclined transportation, and can quickly complete corn loading, unloading, stacking and other operations.

What materials are suitable for conveying with a hose conveyor

The corn hose conveyor drives the internal spiral auger to rotate through the drive motor, pushing corn and other particles forward along the hose to achieve continuous transportation of materials. Because the hose is flexible, the equipment can cross obstacles and bypass space restrictions to a certain extent, and can be used in vertical, inclined or horizontal positions. Suitable for conveying grains of crops such as corn, wheat, soybeans, and rice; feed pellets, premixes; plastic pellets; powder materials (limited to types that are not easy to adhere to and not easy to clog).

Classification of Hose Grain Suction Machines

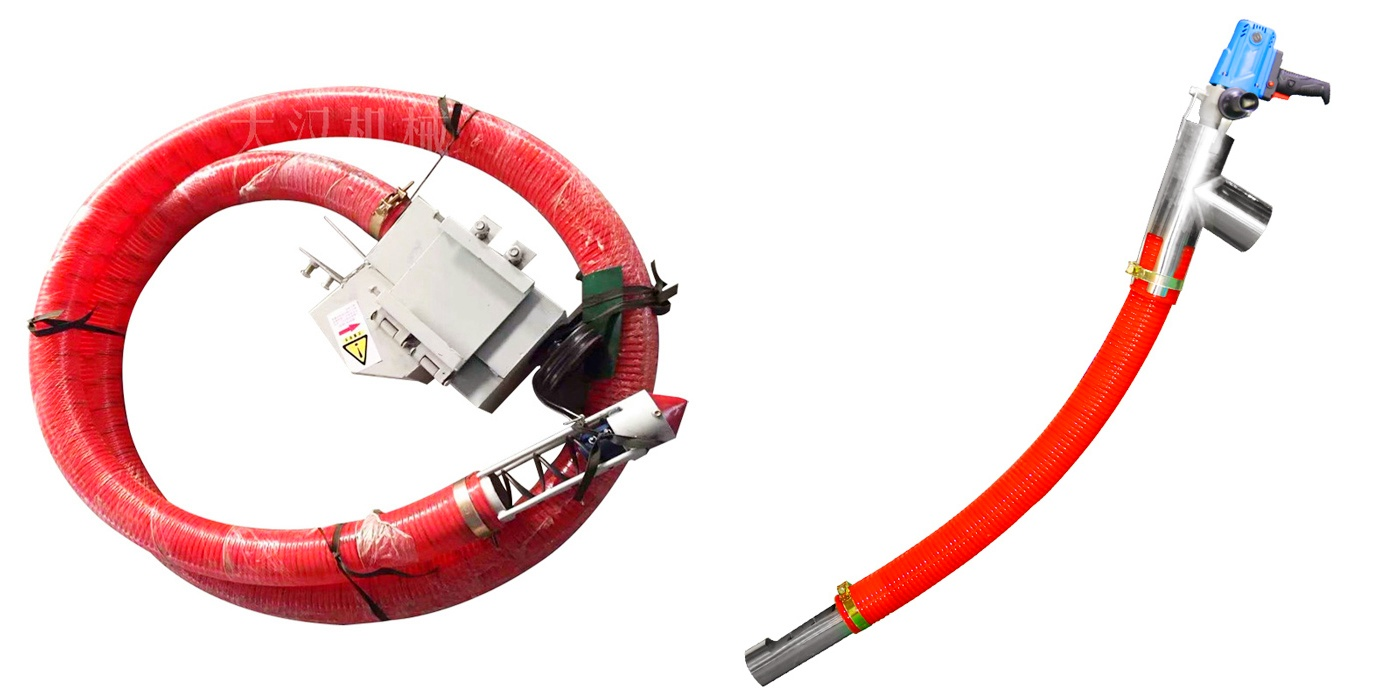

Hose grain suction machines can be divided into two categories: large-scale grain suction machines and agricultural portable hose conveyor for corn according to different structural dimensions, usage scenarios, and conveying capacities, each with different functional characteristics and scope of application.

Large hose conveyor for corn are usually equipped with larger diameter conveying pipes (such as Φ125mm or above), high-power motors (3.0kW-5.5kW), and reinforced steel wire spiral auger. They are suitable for places with large workloads and high frequency of operations such as grain depots, grain stations, and large feed mills. Some models are also equipped with large-capacity feed hoppers and automatic control systems to achieve continuous operation and large-flow conveying. The conveying capacity can reach 10-20 tons per hour, and the conveying distance can reach more than 15 meters. It is suitable for high-load conditions such as loading, warehousing, and unloading. The conveying volume per hour can reach 20-100 tons, and the conveying distance can reach 50-200 meters.

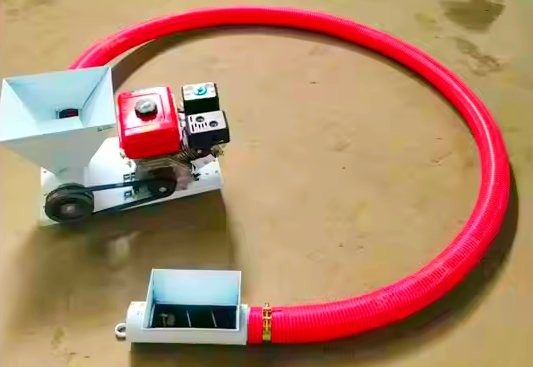

Agricultural portable grain suction machines are mainly used in individual farmers, small grain purchasing points and other application scenarios, emphasizing portability and operational flexibility. This type of equipment usually uses a Φ75mm or Φ100mm hose, with a conveying length of 3-10 meters, a small motor power (1.5kW-3.0kW), a light weight, and can be moved by one person, suitable for household or small-scale grain bagging and warehouse operations. Some models are equipped with universal wheels and adjustable hose brackets, which are convenient for use in farmlands, courtyards, warehouses and other environments. The conveying distance is about 1-10 tons per hour, and the conveying distance is generally 10-50 meters.

Corn hose conveyor-an efficient grain suction solution

Corn is a grain with full grains and strong fluidity. It is easy to be damaged due to mechanical friction during transportation. The corn hose conveyor has a targeted design and has become an ideal grain suction solution. Its core is to control the corn transportation breakage rate below 0.2% through the cooperation of wear-resistant tendon hose and spiral spring structure, while achieving efficient operation: the hourly transportation volume reaches 2-30 tons, the horizontal transportation distance is 3-35 meters, and the lifting height is 4-8 meters. Whether it is batch stacking in grain depots, loading in farm fields, or docking of feed factory production lines, it can be flexibly adapted.

The power system of the equipment is both practical and flexible, providing 220V household/380V industrial dual voltage options, 3-4KW power to cover different scene requirements, and portable models with gasoline/diesel engines, which can better adapt to field operations without power supply. The portable model weighs only 10-30 kilograms and can be carried by one person. The design of the hose bending radius ≥1 meter allows the equipment to shuttle freely in narrow spaces such as agricultural vehicles and warehouse corners, while the large model relies on metal frames and vehicle-mounted devices to meet the continuous and large-scale transportation of grain depots, docks and other places.

|

Model |

Conveying pipe diameter |

Conveying length |

Conveying capacity (t/h) |

Motor power (kW) |

|

Φ75 hose machine |

75mm |

3-8 meters |

3-6 |

1.5-3.0 |

|

Φ100 hose machine |

100mm |

3-10 meters |

5-10 |

2.2-4.0 |

|

Φ125 hose machine |

125mm |

4-12 meters |

8-15 |

3.0-5.5 |

What is the purpose of hose conveyor for corn

In the fields or farmers' homes after corn harvest, it can directly suck the corn kernels scattered on the ground or the corn cobs after threshing into bags, load or transport them to the drying yard, greatly reducing the physical labor of farmers and improving the efficiency of primary grain collection. Secondly, during the corn drying process, if the corn is piled too thick or needs to be turned over, the hose suction machine can easily transfer the wet corn from one area to another for even spreading to ensure the drying effect.

Entering the corn storage link, whether it is a farmer's small granary or a large grain reserve, the hose conveyor for corn is an ideal tool for storage and unloading. It can efficiently transport corn from the transport vehicle to the high granary, or perform internal stacking and warehouse replacement during corn storage to prevent mildew and pests and ensure corn quality. When corn needs to be shipped out of the warehouse or shipped out, it can quickly suck the corn out of the granary and load it onto a truck, train or ship for rapid shipment.

In addition, in industrial scenarios such as feed mills and corn deep processing enterprises, hose conveyor for corn are also often used to transport corn from the raw material warehouse to the entrance of the crusher, mixer or production line as a key material transfer equipment in the production process.

In short, the corn hose conveyor for corn, with its flexible, efficient and low-loss characteristics, runs through every key link from the field to the table of corn, and is an indispensable tool for modern corn processing.