Inclined screw conveyor for chemical particles

Sunday April-27 2025 18:13:36

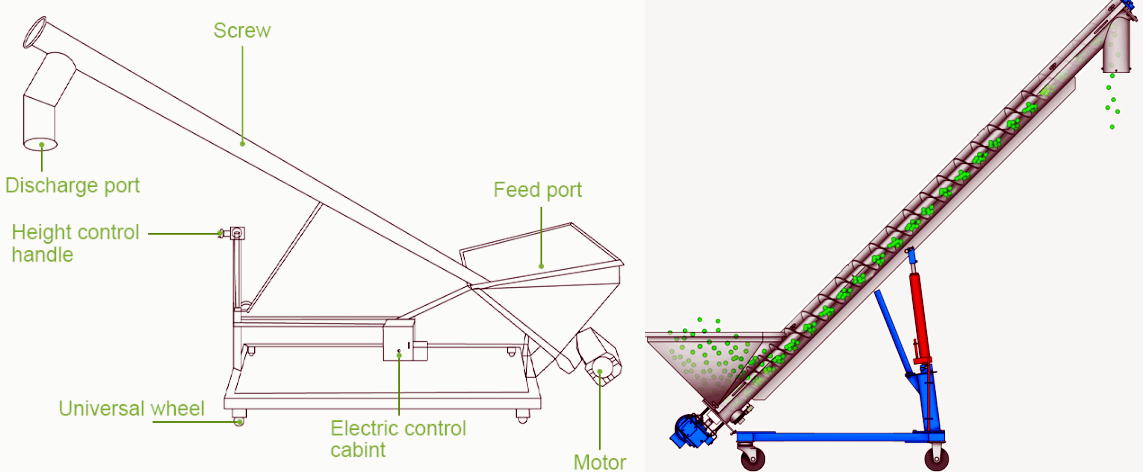

Inclined screw conveyor for chemical particles is specially designed for the chemical industry to efficiently and stably convey various granular materials. The equipment adopts a closed trough structure to effectively prevent dust leakage and protect the production environment. According to the characteristics of the conveyed material, spiral blades of different materials can be selected. For materials that require preliminary screening, a screening device can be integrated, and the mesh size of the screen can be selected according to demand, usually in the range of 10-100 mesh, to remove oversized impurities. The conveyor inclination angle is adjustable, up to 45 degrees, and the conveying capacity ranges from 1-10 tons/hour, depending on the material density and screw diameter.

Video of the inclined screw conveyor for chemical particles

What is the working principle of the inclined screw conveyor for chemical particles?

The inclined screw conveyor for chemical particles pushes chemical particles (such as fertilizers, carbon black, soda ash, etc., with a particle size of 0.074-4mm and a screening mesh of 4-200 mesh) along the inclined machine trough through rotating spiral blades to achieve continuous conveying of materials. Its working principle is as follows:

① Material entry: Chemical particles enter the conveying trough through the feed port (usually a batching hopper or a vibrating feeding device).

② Spiral push: The motor drives the reducer to drive the spiral shaft to drive the blade to rotate (the speed is generally 20-80r/min). The rotating blades generate axial thrust, pushing the particles upward and forward along the trough body.

③ Inclined conveying: Under the action of the inclination angle, the material moves along the trough body under the combined action of gravity and spiral thrust, which is suitable for short distances (5-30m) and medium and low height lifting.

④ Material discharge: The particles reach the discharge port (multiple discharge points can be set) and are discharged to the next process by gravity or auxiliary devices.

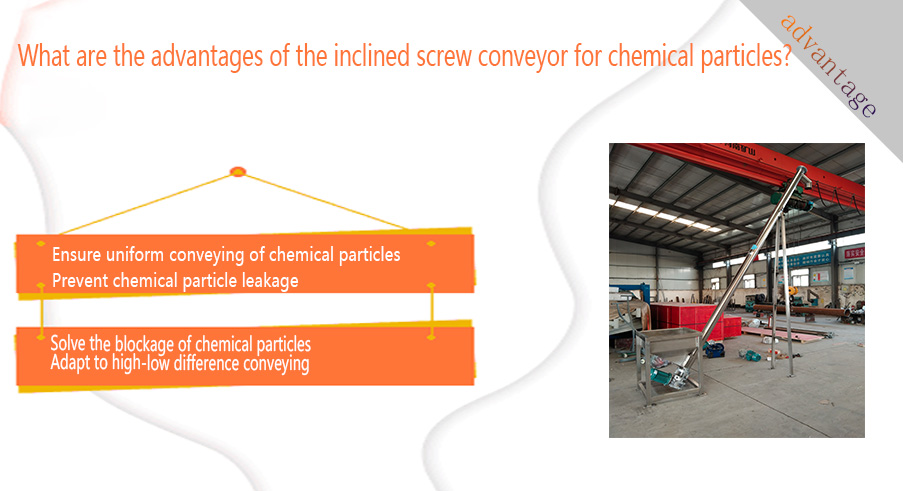

What are the advantages of the inclined screw conveyor for chemical particles?

Ensure uniform conveying of chemical particles: The particle size, shape and density of chemical particles vary greatly, resulting in uneven material conveying, which may cause problems such as unstable flow and material stratification. The inclined screw conveyor can achieve relatively uniform conveying according to the different characteristics of the material (such as particle size, density, etc.) through the precisely designed spiral blades and the adjustment of the conveying angle.

Prevent chemical particle leakage: During the conveying process, especially fine chemical particles or powders, dust leakage is prone to occur. Inclined screw conveyors for chemical particles usually adopt a closed design. This closed structure effectively prevents the leakage of dust, ensures the sealing of materials during the conveying process, and avoids environmental pollution.

Solve the blockage of chemical particles: Chemical particles may cause blockage during the conveying process due to material adhesion or uneven particle size, especially in areas where the conveying pipeline is bent or tilted. The inclined screw conveyor uses the rotation of the spiral blade to push the material forward. This design can effectively reduce the contact surface between the material and the pipeline and avoid blockage caused by material adhesion.

Adapt to high-low difference conveying: In some production environments, space is limited or materials need to be conveyed to different heights. The inclined design of the inclined screw conveyor for chemical particles allows it to transport materials in limited space, and is particularly suitable for situations where height difference transportation is required. It can effectively utilize vertical or slope space and save floor space of the production line.

Application of inclined screw conveyor for chemical particles

Inclined screw conveyor for chemical particles is widely used in the chemical industry, especially for conveying various granular and powdery materials. Its structural design can effectively cope with the needs of conveying materials with high and low differences, especially in narrow spaces or complex production environments.

Fertilizer production line: Raw materials (such as nitrogen fertilizer, phosphate fertilizer, etc.) often need to be conveyed from one process to another. Due to the different particle size, density and fluidity of fertilizer particles, the angle and speed of the screw conveyor can be adjusted according to demand, and the fertilizer particles can be efficiently conveyed from the silo to the mixing, packaging or storage area.

Plastic pellet conveying: Plastic pellet inclined screw conveyor can effectively maintain the integrity of plastic pellets, unaffected by the environment, and ensure continuous production. Different plastic pellets may have different fluidity. By adjusting the mesh size (such as 80 mesh, 100 mesh) and the conveying speed, it can adapt to the needs of different granular materials.

Conveying of mineral particles: When handling mineral particles, the inclined screw conveyor for chemical particles can effectively convey particles of different sizes and densities to the designated location. Mineral particles may have a large particle size and high density. Therefore, the design of the screw conveyor needs to have a strong load-bearing capacity and wear resistance to ensure that no damage occurs during the conveying process.

Particle conveying in food processing: The conveying of granular materials such as seasonings and grains, the inclined screw conveyor can effectively ensure that the material is not contaminated during the transmission process. By adjusting the design of the conveyor, the conveying flow of materials of different particle sizes can be controlled to avoid material waste or cross contamination, and maintain the safety and hygiene of food.

Precautions for inclined screw conveyor for chemical particles

Inclination limit: Too large inclination (>15°) may cause material backflow or decreased conveying efficiency.

Material characteristics: Avoid conveying materials that are easy to agglomerate, highly viscous or high temperature to prevent blockage or equipment wear.

Ambient temperature: The working environment is generally -20℃ to 40℃, and the material temperature should not exceed 80℃.

Maintenance: Regularly check the wear of spiral blades and trough gaskets to ensure sealing and conveying efficiency.

In short, inclined screw conveyors for chemical particles are widely used in various production links of the chemical industry due to their strong adaptability, simple structure and convenient maintenance. They realize efficient and automatic conveying of granular materials and provide strong guarantees for the continuity, automation and safety of chemical production. Its specific application scenarios and selection need to be comprehensively considered based on factors such as the characteristics of the conveyed materials, conveying volume, conveying distance and process requirements.