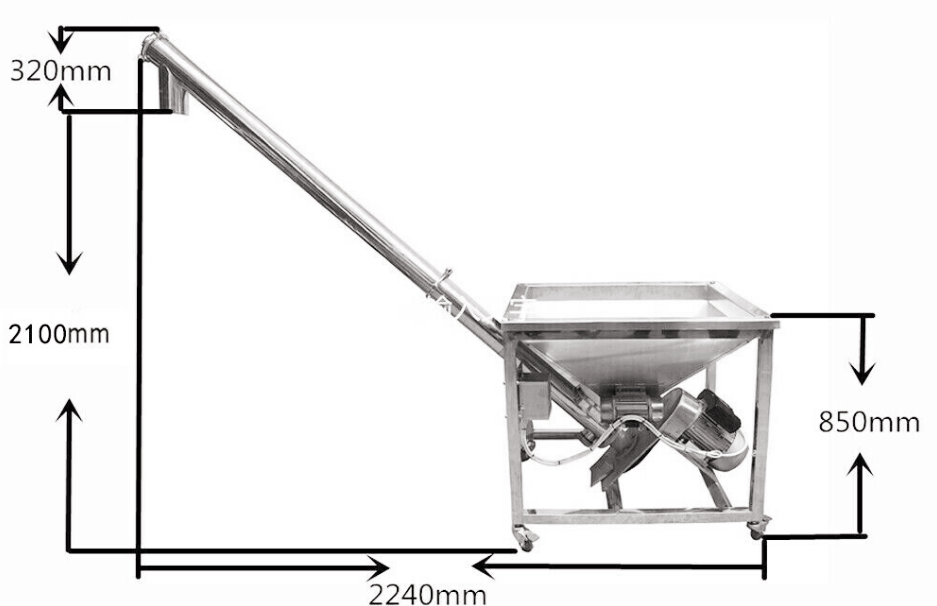

Lime Powder Mini Auger

Thursday May-15 2025 17:25:57

What is a lime powder mini auger?

The lime powder mini auger is a compact conveying equipment specially used for conveying fine-grained powder materials. It is suitable for lime powder conveying processes with a screening size between 80 mesh and 200 mesh. Lime powder has the characteristics of fine particle size, easy dust, strong hygroscopicity and certain corrosiveness, and has high requirements for the sealing and corrosion resistance of the conveying equipment.

Applicable materials and applications of lime powder mini auger

Lime powder is a powder material with a small particle size (<200μm), easy dust, easy hygroscopicity, general fluidity and certain corrosiveness. When conveying, it is necessary to take into account the sealing, anti-blocking and equipment corrosion resistance. The micro screw conveyor is suitable for:

Chemical laboratory

Building materials test line

Small lime powder dosing system

Measuring and conveying of lime powder in food additive or auxiliary material system

Differences between shafted screw conveyor and shaftless screw conveyor

The following are the differences between shafted screw conveyor and shaftless screw conveyor in terms of structural characteristics and lime Comparison table of powder conveying applicability:

|

Project |

Shafted mini auger |

Shaftless mini auger |

|

Image |

|

|

|

Spiral structure |

Spiral blades with central shaft |

No central shaft, only integral spiral body |

|

Applicable material characteristics |

Applicable to dry, powdery or granular materials with good fluidity |

Applicable to materials with high viscosity, easy to entangle or difficult to flow |

|

Applicability of lime powder |

High applicability, stable structure, uniform conveying |

Can be used, but easy to wear and uneconomical |

|

Equipment wear |

Normal wear, long life |

Lime powder is easy to cause dry grinding between the spiral and the trough, easy to wear |

|

Cleaning and maintenance |

Easy to clean, standard structure |

Not easy to clean, especially when conveying dry powder materials |

For lime powder materials with a screening of 80 mesh to 200 mesh and certain dustiness and fluidity, the shafted screw conveyor is more suitable and can better meet the requirements of sealing, stability and service life; while the shaftless structure is more suitable for conveying high viscosity or easy to entangle materials, and is not the first choice for lime powder conveying.

Working principle of lime powder mini auger

The working principle of lime powder mini augur is mainly based on the screw conveying mechanism, and its specific process is as follows:

① Feeding: Lime powder enters the feed port of the micro screw conveyor from the silo or other feeding equipment. The feed port is usually designed as a funnel shape to facilitate the smooth flow of materials.

② Spiral rotation: There is a spiral blade inside the equipment, which is usually fixed on a central axis (in a shaft conveyor). When the motor is started, the spiral blade begins to rotate. The rotation of the spiral blade generates a driving force that can push the lime powder forward along the conveying pipeline.

③ Material conveying: Under the action of the spiral blade, the lime powder is continuously pushed to the outlet of the conveyor. Due to the shape of the spiral, the material will be continuously lifted during the conveying process to adapt to different inclination angles.

④ Discharging: When the lime powder reaches the outlet of the conveyor, the material is discharged from the discharge port by gravity or the driving force of the spiral, and can be directly sent to the next processing link or storage Storage equipment.

Structural composition

The lime powder mini augur is usually composed of the following parts:

Spiral blades: The material is usually stainless steel or carbon steel, and the form is an equal pitch solid spiral or a ribbon spiral, and the diameter is generally between Φ50~Φ114mm.

Shell: It is a circular tubular closed structure, often made of seamless steel pipe, and the inner wall needs to be smooth to reduce the adhesion of lime powder.

Motor and reducer: Generally equipped with a small power motor (such as 0.18~0.75kW), driven by direct connection or coupling.

Feed inlet and outlet: It can be set as flange connection, quick installation or customized interface according to the process layout.

Bearing and sealing device: To prevent dust leakage, the shaft end seal generally adopts labyrinth seal or packing seal.

In summary, the lime powder mini auger drives the spiral blade to rotate through the motor, and uses the axial thrust to transport the lime powder to the target position in a closed and continuous manner. It is particularly suitable for use in working conditions with limited space, small output, and high requirements for cleanliness and sealing.