Lime Vertical Bucket Elevator For Cement Plant

Tuesday June-10 2025 17:03:25

The lime vertical bucket elevator for cement plants is a vertical conveying equipment specially designed for cement plants based on the characteristics of lime materials. Lime has the characteristics of different particle sizes and strong abrasiveness, and powdered lime is easy to generate dust. The elevator adopts a closed structure, with wear-resistant plate chains or belts as traction components, and a large-capacity deep bucket, which can effectively prevent material leakage and equipment wear.

In actual application, its lifting height can usually reach 20-40 meters, or even higher, which can meet the needs of cement plants to transport lime from ground silos to kiln tops, batching warehouses and other high places, and realize continuous and efficient operation. It not only has a large conveying volume, but also has almost no material return phenomenon, effectively reducing energy consumption. At the same time, the stable lifting effect ensures the continuity and stability of lime supply in the production process of cement plants.

Applicable materials for vertical bucket elevators

The lime materials that can be transported by vertical bucket elevators include: quicklime (calcium oxide), slaked lime (calcium hydroxide), limestone powder, lime blocks (depending on the particle size and hardness to determine whether they can be adapted), etc., and the materials are usually required to be dry or slightly moist powder, granular or small blocks, and not abrasive. For high temperature or corrosive lime materials, chains and buckets made of high temperature resistant and wear-resistant materials should be selected.

What is the difference between bucket conveyors and bucket elevators?

Bucket elevators

Direction: Mainly used for material transportation in vertical or near vertical directions. It is particularly suitable for occasions where materials need to be lifted from a lower position to a higher position.

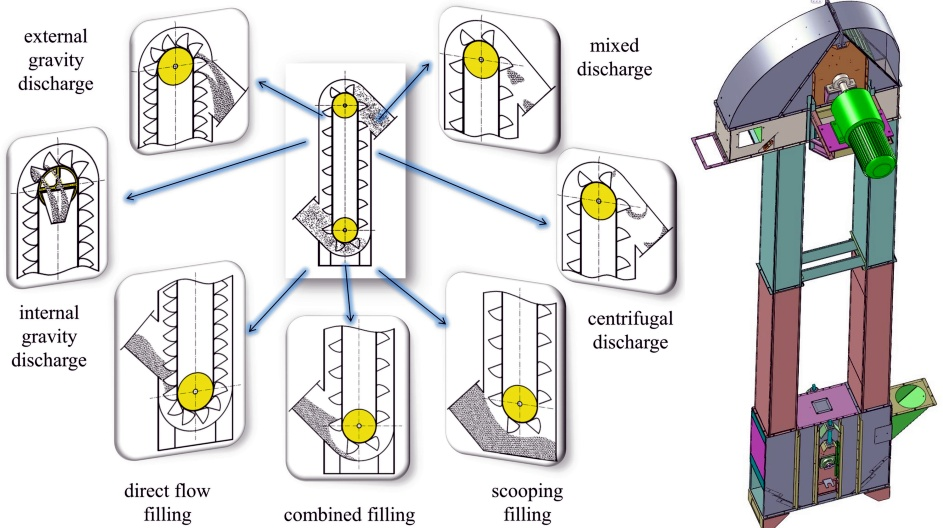

Structural features: It usually consists of a series of buckets evenly distributed on a belt or chain, which move with the cyclic motion of the traction member. As the buckets rise, they load the material and unload the material at the top.

Application scenarios: Commonly used in cement plants, chemical plants, grain processing and other industries to handle the vertical lifting of granular or powdered materials.

Bucket conveyor

Direction: Bucket conveyors can be designed for horizontal, inclined or even vertical material handling, but are more commonly used for horizontal or slightly inclined material transportation.

Structural features: Different designs are used to adapt to its non-vertical transportation needs. For example, it can use continuous chain plates or special guide rail systems to support the smooth operation of the bucket.

Application scenarios: Suitable for occasions where material handling is required within a short distance, such as material transfer between different processes within the factory.

How does the lime vertical bucket elevator for cement plants work?

The vertical bucket elevator of lime is mainly used in cement plants to vertically transport materials such as crushed limestone. Its working principle is based on a continuously circulating traction member (usually a belt or chain) and a hopper fixed on it, and the upward conveying of materials is achieved through the power provided by the drive device.

① The material enters from the feed port below and falls into the hopper at the bottom by gravity. In order to ensure that the material can be smoothly loaded into the hopper, a specific feeding device is usually designed to guide the material.

② The hopper loaded with materials is driven by the traction member installed on the belt or chain and moves upward along the track in the middle casing. In this process, the hopper rises steadily at a certain speed until it reaches the top.

③ When the hopper reaches the upper section, due to the change of trajectory (for example, through the steering of the head axle), the hopper will tilt, causing the material inside to pour out due to gravity, thereby completing the unloading. The empty hopper after unloading continues to return along the downward side to prepare for the next round of loading.

④ The hopper after unloading the material returns to the bottom of the equipment along the downward part of the traction member, and re-participates in the material loading and conveying process, forming a complete cycle.

What is the role of lime vertical bucket elevator for cement plant

Vertical bucket elevator plays a vital role in lime cement plant. Its core role is to realize the vertical and efficient transportation of block, granular or powdered materials such as limestone, raw meal powder, cement clinker, slag, coal powder, etc.

After raw material crushing: lift the qualified limestone to the pre-homogenization bin or raw meal grinding bin to provide continuous and stable raw materials for subsequent grinding process.

After raw meal grinding: lift the ground raw meal powder to the raw meal homogenization bin or kiln tail preheater to ensure that the material can smoothly enter the calcination system.

After cement clinker cooling: lift the clinker coming out of the cooler to the clinker bin, or directly send it to the cement mill for grinding.

Before cement milling: lift clinker, gypsum, mixed materials, etc. to the cement grinding bin according to the proportion to ensure the continuity of cement production.

After coal powder preparation: lift the ground coal powder to the coal powder bin for combustion in the rotary kiln or dryer.

These application scenarios require the elevator to have the characteristics of high lifting height, large conveying volume, low energy consumption, stable and reliable operation, so as to meet the needs of 24-hour continuous production in cement plants, thereby effectively improving production efficiency, reducing labor costs, and reducing the plant area.

The lime vertical bucket elevator for cement plants is a key equipment dedicated to vertical conveying of block, granular or powdered lime in cement production lines. In cement plants, the selection of vertical bucket elevators for lime should be based on the corrosiveness and high density of lime, and plate chain high-strength equipment should be preferred to ensure that the conveying volume (100-1000 t/h) and lifting height (20-40 meters) match the process requirements.