Low Price Industrial Conveyor System Small Vertical Bucket Elevators

Monday May-19 2025 16:49:23

Small vertical bucket elevator is a vertical material conveying equipment commonly used in industrial conveyor systems. It is suitable for small production or local conveying needs. It is usually used for continuous lifting of powdered, granular and small block materials. It is a conveying equipment that mainly uses a hopper evenly fixed on a traction member (such as a belt or chain) as a carrier to continuously lift materials from a low vertical or nearly vertical direction to a high position. Compared with large equipment, its lifting height, conveying capacity and structural dimensions are relatively small, and it is suitable for industrial occasions with limited space or low conveying volume.

Applicable material range of small vertical bucket elevators for low price industrial conveyor systems

Small bucket elevators are suitable for dry materials in powder, small particles, and short fibers, such as:

Grain: rice, corn, wheat, etc.;

Chemical powder: calcium carbonate, zinc oxide, PVC powder, etc.;

Building materials: cement, lime powder, mortar additives, etc.;

Others: feed particles, Chinese medicine powder, plastic particles, etc.

Note: The material should not contain too much viscosity or moisture, otherwise it is easy to cause blockage or adhesion.

The basic structure of small vertical bucket elevators for low price industrial conveyor systems

Small bucket elevators usually consist of the following main parts:

Bucket: used to load and lift materials. According to the characteristics of the conveyed material, carbon steel, stainless steel, and plastic materials can be selected, and the common bucket width is between 100mm and 300mm.

Traction components: usually use tape (belt elevator) or chain (ring chain or plate chain). Low priced models are mostly driven by rubber conveyor belts, which are low in price but less wear resistant than chains.

Drive device: including reduction motor, main shaft, and transmission wheel. Ordinary motors of 0.75kW to 2.2kW can be selected for low power segment.

Head and tail parts: including rollers, bearings, tensioning devices, etc.

Closed barrel: plays a guiding, sealing and dust proof role, generally made of carbon steel or galvanized sheet.

Working principle

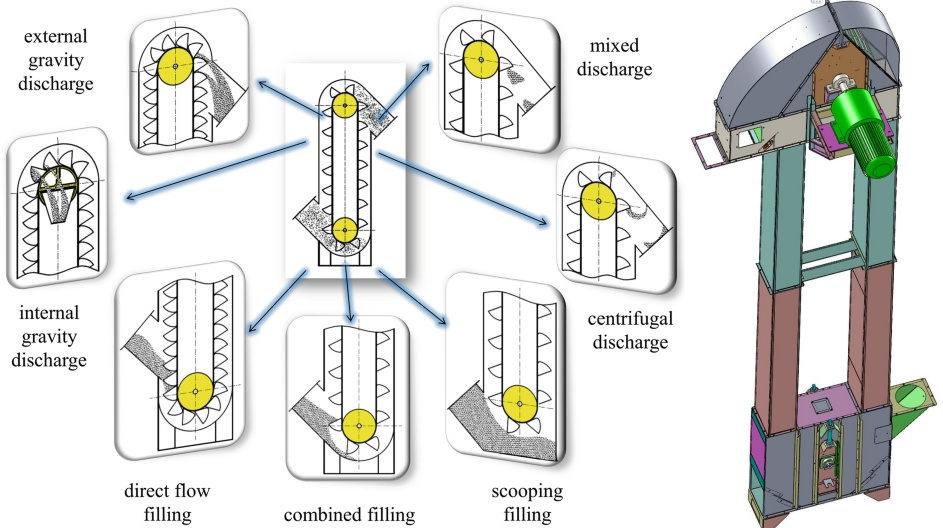

Small bucket elevators feed through the bottom, and the material enters the running bucket; driven by the drive device, the bucket rises along the traction member, brings the material to the top and unloads it by centrifugal force or gravity; the empty bucket continues to return to the bottom for circulation. Its continuity depends on the bucket distance and running speed, and is often based on "inflow feeding and centrifugal unloading".

Examples of common model parameters

Model bucket width (mm) lifting height (m) conveying capacity (t/h) motor power (kW) traction method

TD160 160 3~10 1~3 0.75~1.5 rubber belt

TD250 250 3~15 3~6 1.1~2.2 rubber belt

TD315 315 5~20 4~8 1.5~3.0 rubber belt

These models belong to the small size models of common belt bucket elevators, which are suitable for medium and low volume production occasions and have high price performance.

What are the advantages of small vertical bucket elevators for low price industrial conveyor systems?

Reasonable design of hopper spacing: By calculating the material filling rate and lifting speed, the hopper spacing is determined to avoid material overflow due to collision or too dense spacing during hopper operation. For example, when conveying granular materials, the hopper spacing is usually 1.5 2 times the hopper depth to ensure that there is no residual material accumulation at the bottom of the hopper after unloading.

Hopper edge design: The edges of the shallow and deep hoppers are arc shaped to reduce material adhesion and retention; a rib is set at the edge of the hopper at the discharge port to prevent the material from splashing outward during centrifugal discharge.

Leak proof design of the bottom feed port: The gap between the feed port and the hopper belt is controlled at 5 10mm, and is blocked with an elastic rubber curtain or an adjustable baffle to prevent the material from leaking from the bottom gap during the lifting process.

Optimized discharge method Centrifugal discharge is suitable for small and medium sized particles and materials with good fluidity (such as grains and coal powder). When the hopper runs to the top, the centrifugal force is used to throw the material to the discharge port, and the discharge speed is fast to reduce retention; gravity discharge is suitable for large pieces of material or materials that are afraid of breaking (such as fruits and ores). The hopper is turned vertically for discharge, which is slow but avoids material impact blockage.

Anti blocking structure design: The width of the discharge port is 10 20mm larger than the width of the hopper, and the height is designed according to the material repose angle (usually 1.2 times the depth of the hopper) to ensure smooth discharge of materials.

Application of small vertical bucket elevators in low price industrial conveyor systems

In grain processing plants, small vertical bucket elevators transport cleaned wheat and rice from the ground to the storage bins in the processing workshop to feed the grinding and rice milling processes; in chemical production lines, it lifts dried fertilizer particles or pigment powders to the top of the mixer to achieve precise batching; in building materials plants, it can lift crushed sand and cement powder from the ground to the batching bin to meet the needs of concrete mixing; in small mines, it can lift the screened ore particles to the conveyor belt or transport vehicle; even in small food processing plants, it can be used to transport roasted nuts and grains to the packaging link. This equipment plays an important role in the vertical transportation of materials in various industries with its advantages of low price, small footprint and convenient installation.

Price reference range

According to the average survey of Dahan customers, the ex factory price of a small belt bucket elevator is about RMB 2,500 to RMB 12,000 per unit, depending on the height, material and configuration. For example:

TD160 carbon steel bucket, 3 meters high, ordinary motor configuration, the price is about 2,800 yuan;

TD250 stainless steel bucket, 8 meters high, with observation window, the price can reach more than 9,500 yuan.