Powder Mini Auger

Wednesday April-30 2025 17:51:41

Powder mini auger is a miniaturized device designed for continuous and controllable conveying of powders or fine particles. It can handle fine materials with a particle size of ≤50μm (300 mesh) and is widely used in industries that require precise material conveying. Its core function is to achieve quantitative and continuous conveying of powder materials through a spiral structure. The device adopts a variable pitch spiral shaft structure, with a common spiral diameter of 16mm or 25mm and a conveying capacity range of 0.1 to 50kg/h.

Applicable materials for powder mini auger

Powder mini auger is suitable for conveying various dry powdered materials with good or slightly poor fluidity. Due to its compact structure and small conveying volume, it is often used in fine and small-dose powder conveying scenarios. The following are some typical applicable materials:

Food industry: milk powder, flour, starch, powdered sugar, food additives, seasoning powder, coffee powder, cocoa powder, etc.

Pharmaceutical industry: API powder, pharmaceutical intermediates, auxiliary powder, Chinese medicine powder, capsule filling powder, etc.

Chemical industry: fine chemical powder, dyes, pigments, pesticide powder, plastic powder and additives, coating powder, catalyst powder, etc.

Battery industry: lithium battery positive and negative electrode material powder, conductive agent powder, etc.

Other industries and laboratories: ceramic powder, metal powder, abrasive powder, cosmetic powder, powder samples for scientific research experiments, etc.

Video of powder mini auger

What is the working principle of powder mini auger?

The core structure of the powder mini auger is a micro spiral blade (screw), which is installed in a slender pipe or sleeve: the screw is driven by the motor to rotate, and the powder falls into the conveying pipe through the feed port. As the screw rotates, the powder is pushed to the discharge port along the axis.

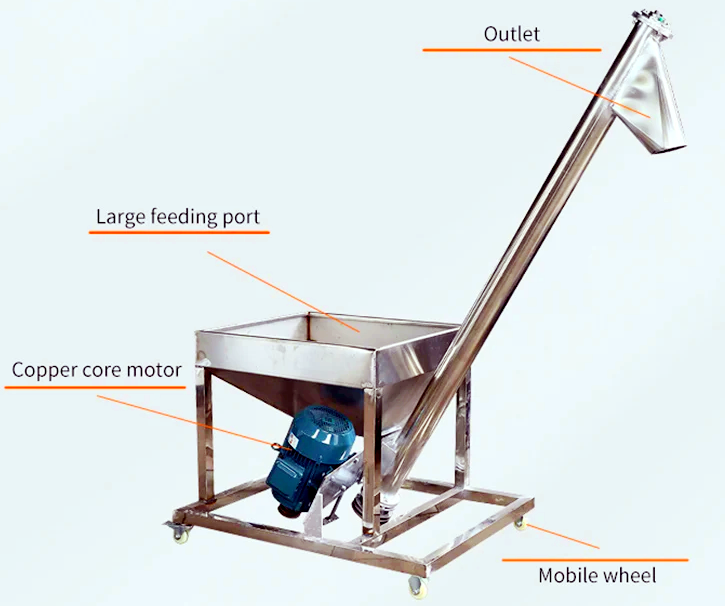

Structure of powder mini auger

Screw shaft: It is the core component of the conveyor, usually made of stainless steel or other wear-resistant materials, with spiral blades welded on it to transmit power and push materials.

Spiral blades: According to the characteristics and conveying requirements of the conveyed material, there are different shapes and sizes. Common ones are solid spiral blades and belt spiral blades. The parameters such as pitch and diameter will affect the conveying speed and conveying volume of the material.

Casing: Powder mini The auger generally adopts a U-shaped or tubular structure to accommodate materials and spiral shafts, play a sealing and protective role, and prevent material leakage and external impurities from entering.

Drive device: including motors, reducers, etc., used to provide power for the rotation of the spiral shaft. The speed of the spiral shaft can be adjusted through the reducer to meet different conveying needs.

Inlet and outlet: The inlet is used to introduce powder materials into the conveyor, and the outlet discharges the conveyed materials to the specified location. The shape and size of the inlet and outlet are designed according to the actual application scenario and material flow rate. Some are also equipped with valves and other devices to control the inlet and outlet of materials.

What are the disadvantages of the powder mini auger?

Particle size sensitivity and breakage risk: When conveying ultrafine powders with a particle size of <50μm, it is easy to flow back through the gap between the spiral and the shell (usually 0.5-1mm), resulting in fluctuations in the conveying volume. For example, when pharmaceutical companies convey micronized lactose (D50=10μm), the actual conveying volume is only 75% of the theoretical value. Reducing the gap can improve leakage, but it will increase wear and energy consumption.

Transport volume index: Due to the miniature design, the diameter and length of the powder mini auger are small, and the pipeline volume is usually from a few liters to tens of liters, which is much lower than that of large spiral pipeline machines (up to hundreds of cubic meters/hour). In the demand for medium or large-volume powder pipelines, micro devices cannot meet the demand, and multiple units need to be connected in parallel or other equipment needs to be used, which increases complexity and cost.

Powder waste and cross-contamination risk: Although the design of the powder mini auger focuses on low dosage, some powders (especially fine or sticky powders) may still be excessive in the spiral blades or trough joints, and adding a cleaning spiral may cause cross-contamination.

Installation and space limitations: Although the micro design is suitable for small spaces, its pipeline path is usually straight or at a limited angle (horizontal, inclined or vertical). In laboratories or compact production lines, if it is necessary to bypass the equipment or achieve multi-point feeding, the micro spiral pipeline machine may need to design an additional arc-shaped trough or adapter to increase and design load.

Application of powder mini auger

Sludge drying powder transportation: used to transport dried sludge powder to storage silos or transport vehicles. Powder mini auger can prevent sludge powder from scattering during transportation and avoid secondary pollution. Its wear-resistant material can adapt to the abrasiveness of sludge powder.

Flour conveying: It is used to accurately convey flour from the storage tank to the dough mixer. Its miniature design can adapt to limited operating space. The stainless steel material meets food hygiene standards to prevent flour from being contaminated. The powder micro screw conveyor can accurately control the amount of each conveying.

Milk powder packaging: In the infant milk powder production line, it is used to convey milk powder from large packaging cans to small packaging machines. The equipment has good sealing performance and can effectively prevent milk powder from being damp and contaminated. Low-speed conveying can reduce the breakage of milk powder particles.

Drug powder addition: It is used to add various drug powders to the granulator in proportion. Powder mini auger can achieve trace and precise addition to ensure the accuracy of the tablet composition. The production of some compound tablets requires a variety of drug powders to be mixed in a specific proportion. The equipment can accurately control the amount of each drug powder added.

If you have specific conveying requirements or material characteristics, we can provide more detailed information so that we can recommend a more suitable powder mini auger type and specification for you.