Rice bran swing screen

Tuesday July-01 2025 15:08:32

Rice bran has the characteristics of light weight, easy to fly, high fiber content, and uneven particles. Conventional vibrating screens are prone to problems such as screen blockage, incomplete screening or material crushing. The swing screen uses a three-dimensional swinging motion of a low-speed elliptical trajectory to make the material move forward in a spiral manner on the screen surface, simulating the manual screening process, which can not only protect the material structure but also achieve efficient grading.

Rice bran swing screen is usually equipped with 2 to 5 layers of screens, and the commonly used screening mesh is 10 to 80 meshes, which can simultaneously achieve operations such as coarse impurity removal, medium bran sorting and fine powder extraction. The screened rice bran can be used for feed, oil extraction or biomass particle processing according to the particle size to improve material utilization efficiency.

What is the main function of the rice bran swing screen?

In the process of rice bran processing, the swing screen is often used in key links such as grading, impurity removal, and pretreatment. The main purpose is to improve the product purity and subsequent utilization rate of rice bran (such as for feed, oil extraction, biomass briquetting, etc.). The first layer of screen is generally 10 mesh (about 2mm), which mainly removes larger impurities such as rice husk flakes, large fibers, wood chips, and stones. The coarse impurities are discharged through the discharge port and enter the waste channel. The second layer of screen is 20-40 mesh (0.45-0.85mm), which screens out rice bran of suitable particle size for feed or briquetting. Usually this layer has the largest output and is the main product output channel. The third layer of screen is set to 60-80 mesh to screen out finer bran powder, such as for vegetable oil extraction or high value-added purposes.

How does the rice bran swing screen work

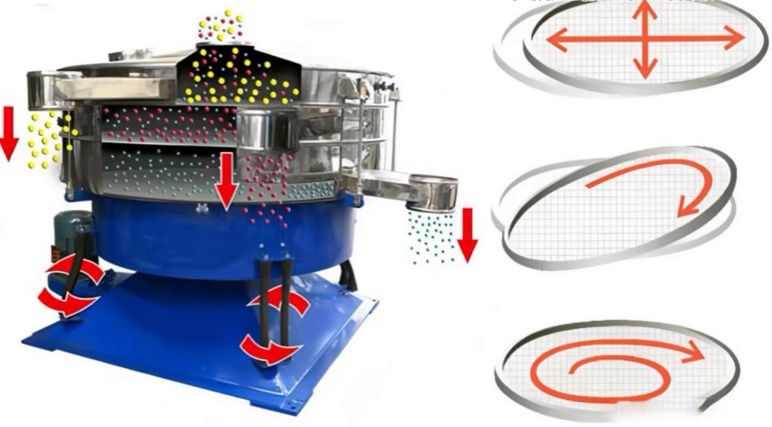

The working principle of the rice bran swing screen is to simulate the manual screening action, through the three-dimensional swinging motion of the low-speed elliptical trajectory, the rice bran slowly rolls, layers, and moves forward on the screen surface, thereby achieving efficient grading and impurity removal.

The rice bran falls evenly from the feed port to the screen surface. Because the material is light, it is often combined with a feed control device to ensure uniform feeding. The drive system drives the eccentric mechanism to make the screen body do an elliptical swinging motion. The screen surface vibrates slowly in both the horizontal and vertical directions, and the material moves forward in a spiral manner.

The rice bran is subjected to the combined effects of inertia, centrifugal force and gravity on the screen. The particles are screened on different layers of screens according to the particle size: particles larger than the screen holes remain on the upper layer, and particles smaller than the screen holes fall into the next layer until the fine bran is discharged from the bottom screen. This low-speed, high-efficiency and gentle screening method is particularly suitable for rice bran, which is a light, fiber-containing and easy-to-float material, and can significantly improve the screening accuracy.

What are the disadvantages of the rice bran swing screen?

In order to realize the spiral diffusion movement of the material, the swing screen is usually designed to be elliptical, and the floor area is 30%-50% larger than that of the vibrating screen at the same processing capacity. For example: a swing screen with a processing capacity of 50t/h occupies an area of about 8-10㎡, while a vibrating screen only requires 5-6㎡, which may limit the equipment layout of small processing plants. Although the swinging motion of the swing screen helps prevent clogging, the screen may still be clogged for extremely wet or very sticky materials. Rice bran may carry a certain amount of moisture and grease in some cases, which may still affect the screening efficiency if not handled properly.

Although the screening accuracy of the rice bran swing screen is high, the processing capacity is limited by the diameter and number of layers of the equipment; for rice bran factories with large single-time processing requirements, large models need to be selected, which further increases costs; if the feed speed is not properly controlled, the "bran powder floating" phenomenon is likely to occur, affecting the grading effect.

Technical parameters of rice bran swing screen

|

Model |

Screen diameter (mm) |

Number of layers |

Power (kW) |

Recommended screen mesh |

Output range (kg/h) |

|

YBS-1200 |

1200 |

3 |

1.5 |

10–60 mesh |

300–1000 |

|

YBS-1500 |

1500 |

3–4 |

2.2 |

10–60 mesh |

500–1500 |

|

YBS-1800 |

1800 |

4–5 |

3.0 |

10–60 mesh |

800–2000 |

What can the rice bran swing screen be used for

Rice bran is a byproduct with light texture, high fiber content and uneven particle size. It is widely used in grain processing, feed manufacturing, biomass energy and other fields. The rice bran swing screen simulates the manual screening action to achieve efficient classification and impurity removal of rice bran, which is especially suitable for occasions requiring fine sorting.

In feed mills, the oscillating screen can be used to grade coarse and fine bran to improve the palatability and nutritional balance of feed; in vegetable oil mills, finely screened rice bran can be used to extract rice oil and improve the purity of oil; in biomass pellet fuel production lines, the oscillating screen can be used to pre-screen large impurities and fine dust, which helps to improve the briquetting rate and combustion calorific value.

The oscillating screen plays a vital role in rice bran screening, mainly in improving the purity of rice bran, reducing the loss of broken rice, and realizing the refined utilization of by-products. It can efficiently separate impurities and obtain rice bran with higher purity, thereby improving the commercial value and utilization efficiency of rice bran.