Sand inclined screw conveyor

Thursday July-03 2025 18:15:26

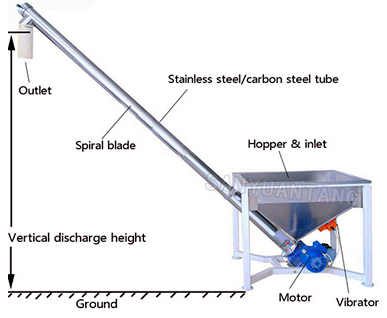

Sand inclined screw conveyor is a mechanical device that transports sand materials upward at a certain angle. It is suitable for quantitative transportation of sand in the fields of construction, sand and gravel, concrete mixing, etc. Because the sand particles are small, the fluidity is good but it has a certain abrasiveness, the theme is equipped with thickened wear-resistant spiral blades to ensure long-term operation stability.

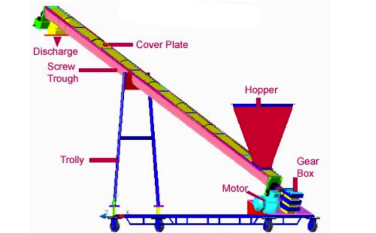

Compared with horizontal transportation, the inclined conveying structure can overcome the height difference restrictions and lift the sand from the ground to the high-level silo or mixer, which is especially suitable for compact sites or high vertical transportation requirements. The conveying angle is generally controlled between 15° and 30°, which can ensure the conveying efficiency and avoid the problem of sand backflow or accumulation and blockage.

When the motor drives the screw shaft to rotate, the spiral blade fixed on the screw shaft will continue to rotate. Since the gravity of the sand will resist the force of its rotation with the screw shaft, the sand will be pushed forward along the spiral direction under the push of the spiral blade, and finally discharged from the discharge port. For inclined conveying, the material will generate a downward component under the action of gravity, but the thrust of the spiral is enough to overcome this component and convey the sand upward.

The structure of the inclined screw conveyor includes a trough body, a spiral blade and a screw shaft, a screw shaft, a feed port and a discharge port. The trough body is mainly used to accommodate sand materials. Compared with ordinary tubular screw conveyors, its U-shaped trough body is relatively large and can carry more sand materials; the screw shaft and spiral blades are important components in the sand screw conveyor. The spiral blades are fixed on the screw shaft, and the spiral blades help the movement of sand materials. The feed port and the discharge port are used for the material in and out, and different forms of feed ports can be designed according to actual needs.

Since sand has a certain specific gravity (generally 1.4~1.6t/m³) and abrasiveness, thickened spiral blades and enhanced motor configurations are usually selected when designing the equipment.

|

Model |

Pipe diameter (mm) |

Pitch (mm) |

Speed (r/min) |

Angle 20°Conveying capacity (m³/h) |

Motor power (kW) |

Applicable conveying length (m) |

|

LS160 |

160 |

160 |

90 |

3~5 |

1.5 |

≤10 |

|

LS200 |

200 |

200 |

80 |

6~8 |

2.2 |

≤12 |

|

LS250 |

250 |

250 |

60 |

10 ~14 |

3.0 |

≤15 |

|

LS315 |

315 |

315 |

50 |

16~24 |

4.0~5.5 |

≤15 |

|

LS400 |

400 |

355 |

40 |

25~38 |

7.5~11 |

≤20 |

Sand usually contains hard particles such as quartz and is highly abrasive. Long-term transportation will cause serious wear on the spiral blades and the trough. Therefore, when choosing a sand inclined screw conveyor, wear-resistant materials are usually used to manufacture the spiral blades and troughs, such as high manganese steel, wear-resistant alloy steel, etc., or surface hardening treatment or wear-resistant lining is performed on the easily worn parts. Sand is easy to adhere to the spiral blades and the trough wall when the humidity is high, resulting in reduced conveying efficiency or even blockage. The design will consider the reasonable gap between the spiral blades and the trough to avoid excessive accumulation of materials.

During inclined conveying, sand and soil tend to fall back under the action of gravity, affecting the conveying efficiency. The pitch and speed of the spiral blades will be optimized according to the characteristics of the sand and soil and the inclination angle to ensure that the material can move upward stably and continuously under the action of the spiral thrust to overcome the fall caused by gravity.

Inclined screw conveyors for sand and soil are widely used in construction projects, concrete mixing plants, sand and gravel processing plants, municipal engineering and underground construction. It is mainly used to transport granular materials such as sand and soil to a high place or a designated position along a certain inclination angle, solving the problem of material lifting when space is limited. In concrete mixing plants, inclined screw conveyors can efficiently transport sand and soil to the batching bin to ensure the continuous supply of mixing raw materials; at construction sites, the equipment is used to transport sand and soil to the floor construction platform.

Construction mortar feeding system

Vertical lifting of sand and gravel in mixing plants

Finished sand loading and bagging in sand fields

Sand and soil transportation system in underground construction

Sand and soil inclined screw conveyors have become an indispensable mechanical equipment in the sand and soil transportation process due to their compact structure, strong sealing, stable transportation and convenient maintenance. It is suitable for all kinds of occasions that require vertical or oblique transportation of sand and soil, especially for environments with limited space, high dust control requirements or strong requirements for transportation continuity.