Sandstone Mineral Drum Screen

Monday June-30 2025 12:16:33

What is Sandstone Mineral Drum Screen

A key advantage of using sandstone mineral drum screens in the screening process of sandstone minerals is its efficient classification and anti-blocking ability. Sandstone often contains particles of different sizes, clay, wet materials and impurities. If it enters the crushing or conveying link directly, it is easy to cause equipment blockage, severe wear or reduced efficiency.

Compared with traditional linear screens or vibrating screens, the sandstone mineral drum screen uses a rotating screen drum structure to slowly roll and disperse the material inside, so that fine materials can pass through the screen smoothly, and large pieces and impurities are discharged forward. The whole process is smooth and not easy to block the holes. It is particularly suitable for the pretreatment of sandstone with high water content and uneven particles.

The difference between shaftless and shafted sandstone mineral drum screens

The shafted drum screen adopts a central axis structure, which drives the screen drum to rotate. The screen drum is supported by the axis and connected to the drive system. It is suitable for materials with uniform particle size and high dryness. It is commonly used in conventional screening processes in sandstone plants or mineral processing plants. Due to the presence of a central axis in the structure, the anti-entanglement ability is weak, and it is easy to get blocked when encountering materials containing impurities such as grass roots and fibers, and the maintenance frequency is relatively high.

The shaftless drum screen cancels the central axis design, relies on the rollers on both sides of the drum to support and is driven to rotate by the outer ring. The structure is simpler and the gravity distribution is more uniform. It is more suitable for screening complex materials with high water content, high viscosity, and easy entanglement, such as wet sandstone, silt or construction waste. It has stronger anti-entanglement ability and better screening permeability. It is widely used in wet material processing, river dredging and complex mineral screening.

If it is dry sandstone (uniform particle size, few impurities), the shaft drum screen has a higher cost performance; if it is wet sandstone or complex materials with mud, weeds, and lumpy ore: the shaftless drum screen is more suitable, with strong anti-winding performance and more stable operation.

How does the sandstone mineral drum screen work?

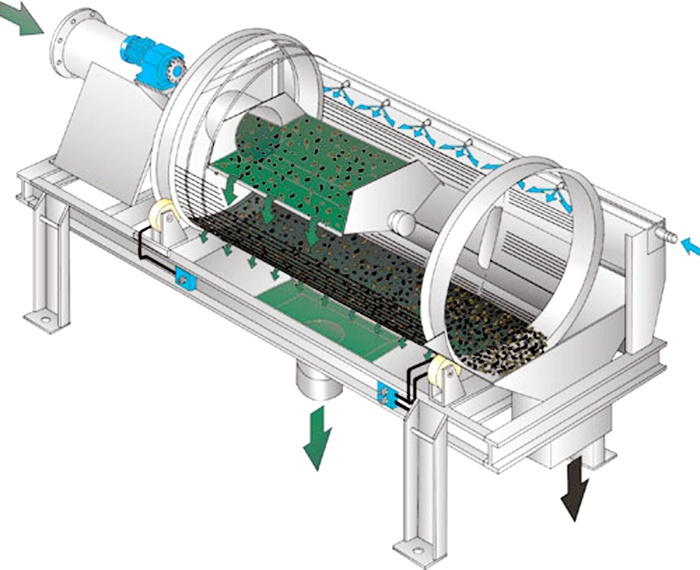

When the sandstone mineral drum screen is working, the motor drives the cylindrical drum device to rotate at a specific speed through the reducer. Screens with different apertures are installed axially in the drum, and spiral blades or guide plates on the inner side of the drum wall assist in the movement of materials. After the sandstone mineral enters the drum from the feed port, it is continuously rolled and slid on the screen during the rotation process under the action of gravity, centrifugal force and friction between materials. Particles smaller than the sieve hole diameter will fall through the screen and be collected by the material receiving device below as underscreen; particles larger than the sieve hole will continue to be pushed by the spiral blades, move to the discharge port, and finally be discharged as overscreen.

What are the advantages of the sandstone mineral drum screen?

In the process of conveying sandstone minerals, problems such as uneven particle size, high mud content, high humidity, and easy clogging of conveying equipment are often encountered. Especially in the primary processing stage, large pieces of stone, clay inclusions and fine powder are mixed together, which can easily cause poor operation of the conveying system, increased equipment wear, and reduced efficiency of subsequent processes. In addition, if the impurities in the material are not separated in time, it may also affect the product quality or cause overload of screening and crushing equipment.

The sandstone mineral drum screen effectively realizes the tumbling, dispersion and grading of materials through the rotating screen drum structure. Large pieces of material are separated and discharged smoothly, and small particles and mud fall through the screen holes to achieve particle size control and pre-screening. Especially when dealing with wet and sticky sandstone, the drum screen structure can prevent the screen holes from being blocked and maintain stable screening capacity. The drum screen not only improves the uniformity and controllability of materials before conveying, but also reduces the frequency of equipment maintenance, providing a more efficient and stable pre-treatment guarantee for the entire conveying system.

Recommended mesh number of sandstone mineral drum screen

|

Sandstone product use, type |

common sieve hole size (mm) |

corresponding approximate mesh number (Mesh) |

remarks |

|

Coarse aggregate, cushion material |

30-80mm |

about 0.2-0.6 mesh |

used for roads, foundation cushion, large concrete structures, etc., mainly to separate large pieces of sandstone |

|

Medium coarse aggregate |

10-20mm |

about 0.9-2 mesh |

used for concrete, asphalt mixture, etc., to screen out medium-sized aggregate |

|

Coarse sand for construction |

4.75-10mm |

about 2-4 mesh |

mainly used for concrete proportioning, usually the primary screening of machine-made sand production lines |

|

Medium sand for construction |

2.36-4.75mm |

about 4-8 mesh |

general-purpose construction sand for concrete, mortar, masonry, etc., this particle size range has a large demand for products |

|

Fine sand for construction |

0.60 -2.36mm |

about 8-30 mesh |

used for plastering, special mortar, fine concrete, etc., requiring finer particles |

|

Extra fine sand, stone powder |

0.15-0.60mm |

about 30-100 mesh |

used for dry-mixed mortar, some industrial sand, or as filler in machine-made sand |

|

Fine industrial sand |

<0.15mm |

>100 mesh |

such as glass sand, foundry sand, etc., have extremely high requirements for particle size distribution and purity |

|

Pre-screening, mud removal |

10-30mm |

about 0.6-2 mesh |

pre-screening before the crusher to remove small-size materials and most of the soil impurities |

What can sandstone mineral drum screen be used for

Sandstone mineral screen is a high-efficiency grading equipment that widely affects sandstone mineral processing. It is used for more particle size separation and transportation of sandstone to meet the needs of construction, highway, concrete and other industries. In the sandstone production line, the sandstone mineral drum screen is used for pre-screening to screen out the raw sandstone containing pigments or large pieces, reducing the burden of the subsequent crusher; after crushing, the sandstone is graded into finished products of different particle sizes, such as 0-5mm fine sand for concrete and 5-20mm crushed stone for roadbed construction.

It is also commonly used in aggregate production to provide qualified sandstone aggregates for roads and water conservancy projects, and can even play a role in the recycling of waste sandstone materials, re-separating the available sandstone particles to maximize the utilization of resources.

For sandstone mineral processing, the drum screen can effectively separate materials of different particle sizes, which helps the smooth progress of subsequent processing processes such as crushing and grinding. In addition, according to different production needs, the drum screen can also be equipped with screens of different aperture sizes to achieve different levels of screening of materials.