Sewage treatment material screw conveyor

Wednesday April-23 2025 17:36:03

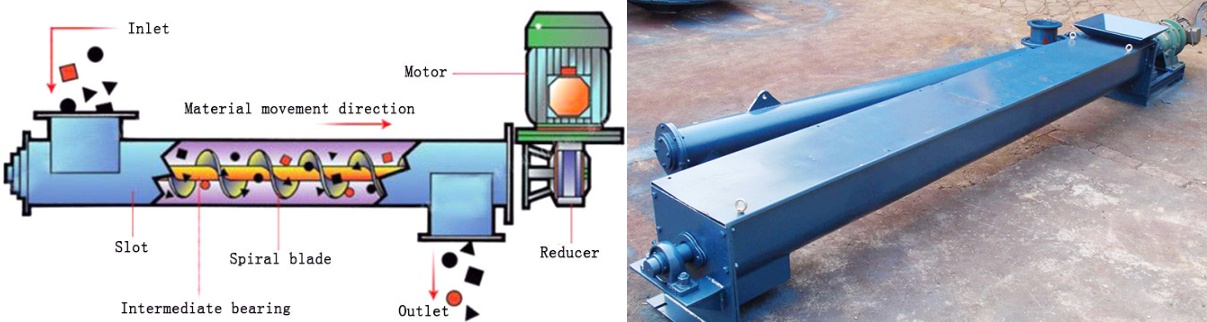

Sewage treatment material screw conveyor is a kind of equipment specially used for conveying solid or semi-solid materials (such as sludge, screen residue, sand, etc.) in the process of sewage treatment. It is widely used in sewage treatment plants, industrial wastewater treatment and livestock waste treatment. It pushes the material in the trough or pipe body through the rotating spiral blade (with or without shaft), and conveys it from the feed port to the discharge port to achieve efficient and sealed material transfer.

Video of Sewage Treatment Material Screw Conveyor

What is the working principle of the sewage treatment material screw conveyor?

The screw conveyor is mainly composed of a drive device, a casing, a screw shaft, a spiral blade, a feed port and a discharge port. Its working principle is as follows:

① The material enters the shell from the feed port, and when the screw shaft rotates, the blade pushes the material to move along the axial direction.

② For sticky materials such as sludge, the sewage treatment material screw conveyor can simultaneously play a stirring and conveying role through the rotation of the blade to prevent material accumulation. Move forward along the spiral channel in the casing, conveying from the feed port to the discharge port

Types of Sewage Treatment Material Screw Conveyors

Depending on different working conditions, common types include:

|

Type |

Features |

Application |

|

Shaftless Screw Conveyor |

No center shaft, suitable for winding, sticky materials such as sludge, screen residue |

Sludge, fibrous garbage conveying |

|

Shafted Screw Conveyor |

High structural strength, suitable for powdery or granular materials |

Sand water, sedimentation and other dry materials conveying |

|

Inclined Screw Conveyor |

Can convey uphill materials at a certain angle |

Dewatering Cake Lifting |

|

Enclosed Structure |

Reduce odor leakage and keep the site clean |

Urban Sewage Station/Food Wastewater Site |

What are the disadvantages of the sewage treatment material screw conveyor?

High requirements for the characteristics of sewage treatment materials: The screw conveyor mainly relies on the thrust of the spiral blades to convey materials. For liquids with excellent fluidity, the conveying efficiency will be very low. During the spiral conveying process, the material will be subjected to extrusion and shear force, which can easily lead to the breakage of fragile materials.

Conveying distance and lifting height are limited: With the increase of conveying distance, the friction resistance between the material and the casing increases, requiring greater driving power, and material blockage is prone to occur. When the inclination angle is too large, the material is easy to slide down, and vertical conveying requires special design, which is costly and has limited conveying capacity.

Easy to block: For materials containing long fibers or strong winding, it is easy to wrap around the spiral shaft, causing blockage, affecting normal operation, and even requiring shutdown for cleaning. Viscous materials are easy to adhere to the spiral blades and the inner wall of the casing, gradually accumulating, resulting in a decrease in conveying capacity or even blockage.

Relatively high energy consumption: During the conveying process, the material rubs against the spiral blades and the casing, and a certain amount of energy is required to overcome the resistance. In particular, the energy consumption of the sewage treatment material screw conveyor will be higher when the conveying distance is long or the material viscosity is high.

Application of sewage treatment material screw conveyor

The application of sewage treatment material screw conveyor is very extensive, covering almost all links in the sewage treatment process involving the conveying of solid or semi-solid materials.

Screen slag removal and conveying: In the pretreatment stage of the sewage treatment plant, the coarse garbage intercepted by the screen needs to be promptly transported to the subsequent treatment or temporary storage area. The shaftless screw conveyor's centerless design can effectively avoid entanglement and handle irregularly shaped, fibrous grit.

Grit tank discharge and transportation: The sand deposited at the bottom of the primary sedimentation tank or aerated grit tank of the sewage treatment plant needs to be discharged regularly. The fluidity of the sand is relatively good, and the shafted sewage treatment material screw conveyor can provide stable transportation.

Primary sedimentation tank sludge transportation: The sludge settled in the primary sedimentation tank needs to be transported to the sludge treatment link. According to the water content and viscosity of the sludge, you can choose a shafted or shaftless screw conveyor. The primary sedimentation tank sludge with high water content and good fluidity can use a shafted screw conveyor.

Dewatered sludge transportation: After the sludge is treated by the dewatering machine, the water content is reduced, but it still has a certain viscosity and agglomeration. The open conveying trough and centerless design of the sewage treatment material screw conveyor are very suitable for handling viscous and easy-to-entangle dewatered sludge, which can effectively prevent blockage.

In short, sewage treatment material screw conveyor is an indispensable key equipment in the sewage treatment plant. It can effectively transport various solid and semi-solid materials and provide guarantee for the subsequent treatment process. When selecting and using it, it is necessary to fully consider the material characteristics and process requirements to ensure the stable and reliable operation of the conveyor.