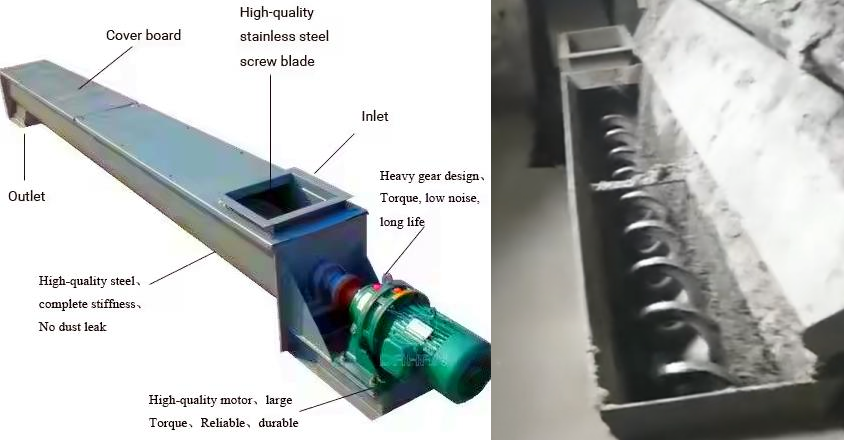

Shaftless screw conveyor for sludge

Monday June-23 2025 18:09:24

What is a shaftless screw conveyor for sludge ?

The advantage of using a shaftless screw conveyor in the sludge conveying field lies in its adaptability to highly viscous and high-water content materials. The sludge is wet and heavy, containing a lot of water and fiber impurities. Conventional shafted screw conveyors are prone to entanglement, blockage and even shutdown during the conveying process. The shaftless screw conveyor for sludge eliminates the central shaft and uses thickened spiral blades to form a larger material passing space, which can continuously and stably push the sludge forward and improve the overall conveying efficiency.

What problems will the sludge screw conveyor encounter during the conveying process?

The sludge screw conveyor is not suitable for large-particle materials and materials with low moisture content. If the sludge contains block impurities with a particle size of >50mm (such as stones, metal fragments), the spiral blades may be stuck, causing the equipment to overload and shut down. It needs to be used with a pre-treatment screen. When the sludge moisture content is <60%, the viscosity is reduced and it is easy to agglomerate. It may slip in the tank and the conveying efficiency is reduced. It needs to be used with a stirring device.

In order to meet the requirements of wear resistance and corrosion resistance, the cost of core components (such as stainless steel spirals and cast stone linings) is 20%~40% higher than that of traditional carbon steel shafted spirals. The inclination angle should not be too large. It is recommended that the conveying inclination angle be ≤15°. If it exceeds 20°, the sludge may slide down due to gravity, resulting in a significant decrease in conveying efficiency, while the shafted spiral can adapt to an inclination of 25°~30°.

Working principle of shaftless screw conveyor for sludge

The working principle of shaftless screw conveyor for sludge is mainly based on the ingenious cooperation between the continuously rotating belt-shaped spiral blades and the specially designed U-shaped trough or tubular trough body, so as to realize the smooth, sealed and non-blocking conveying of sticky and easy-to-entangle sludge.

After the sludge falls into the U-shaped conveying trough from the feed port, the motor drives the shaftless screw (flexible steel blade) to rotate. Due to the design without center shaft, the screw directly contacts the material, avoiding the winding problem that may be caused by the traditional center shaft. The rotating spiral blade pushes the material forward along the bottom of the trough through thrust. New materials are continuously filled in, captured by the subsequent rotating blades and pushed forward. This process forms a continuous material flow that flows steadily from the feed port to the discharge port.

Main technical parameters

|

Model |

Screw diameter (mm) |

Conveying capacity (m³/h) |

Conveying length (m) |

Motor power (kW) |

|

WLS-260 |

260 |

2~8 |

1~30 |

1.5~4 |

|

WLS-320 |

320 |

4~12 |

1~30 |

2.2~5.5 |

|

WLS-360 |

360 |

6~15 |

1~30 |

3~7.5 |

|

WLS-420 |

420 |

8~20 |

1~30 |

4~11 |

What can the shaftless screw conveyor for sludge be used for

In sewage treatment plants, industrial wastewater treatment, urban sludge transportation and other scenarios, shaftless screw conveyors are preferred for conveying medium-to-high moisture content (60%~90%), fiber-containing or viscous sludge.

High viscosity sludge in chemical, papermaking, printing and dyeing, leather and other industrial fields

Sludge and organic waste in urban garbage treatment plants

Dehydrated sludge in urban sewage treatment plants

Wet materials such as food factory waste residues

Difficult to transport media such as oily sludge, organic sludge, and kitchen sludge

Why is a shaftless screw conveyor used for conveying sludge?

A shaftless screw conveyor is used to convey sludge, mainly because sludge has the characteristics of high water content, high viscosity, and easy entanglement. Traditional shafted screw conveyors are difficult to handle, and shaftless structures are more adaptable to such special working conditions.

High water content: The water content of sludge is usually between 60% and 90%, the texture is thick, paste-like, and has poor fluidity, and it is easy to adhere to the surface of the equipment.

High viscosity and high entanglement: Sludge often contains impurities such as fibers, plastics, and hair, which are easy to entangle on the central axis of traditional conveyors, causing jamming or blockage.

Irregular shape: Dewatered sludge is often in block or mass shape, with uneven size and easy to accumulate, resulting in material blockage or poor conveying.

Shaftless screw conveyor for sludge realizes the "propulsion" movement of the material through the rotating shaftless spiral blades, relying on the equipment's own structure to adapt to the characteristics of high viscosity, high moisture, and easy entanglement of sludge, ensuring a continuous, stable, and closed conveying process. When selecting, be sure to make detailed calculations and selections based on the specific sludge characteristics, process requirements, and site conditions, and pay attention to the selection of wear-resistant and anti-corrosion materials for key components (blades, troughs) to ensure long-term stable and efficient operation of the equipment.