Silica grain suction machine

Tuesday April-29 2025 16:33:48

Silica grain suction machine is a suction and processing equipment designed for silica grain, a specific material. Silica grain is a granular material processed from quartz grain. It has the characteristics of high hardness, wear resistance and stable chemical properties. It is widely used in foundry, glass manufacturing, water treatment and photovoltaic materials. It is mainly used for loading and unloading, handling, screening, dust removal and other operations of silica grain.

The core function of the silica grain suction machine

The core function of the silica grain suction machine is to solve these problems through professional design, ensure efficient, accurate and environmentally friendly silica grain processing, and meet the particle size requirements (40-250 mesh, 60-425μm) of industries such as glass manufacturing, casting, ceramics, and water treatment.

① Particle size classification (such as separation of coarse grain, medium grain, and fine grain).

② Remove dust and impurities (such as soil and organic matter).

③ Control the moisture content of silica grain (through drying or moisture absorption design).

What is the working principle of the silica grain suction machine?

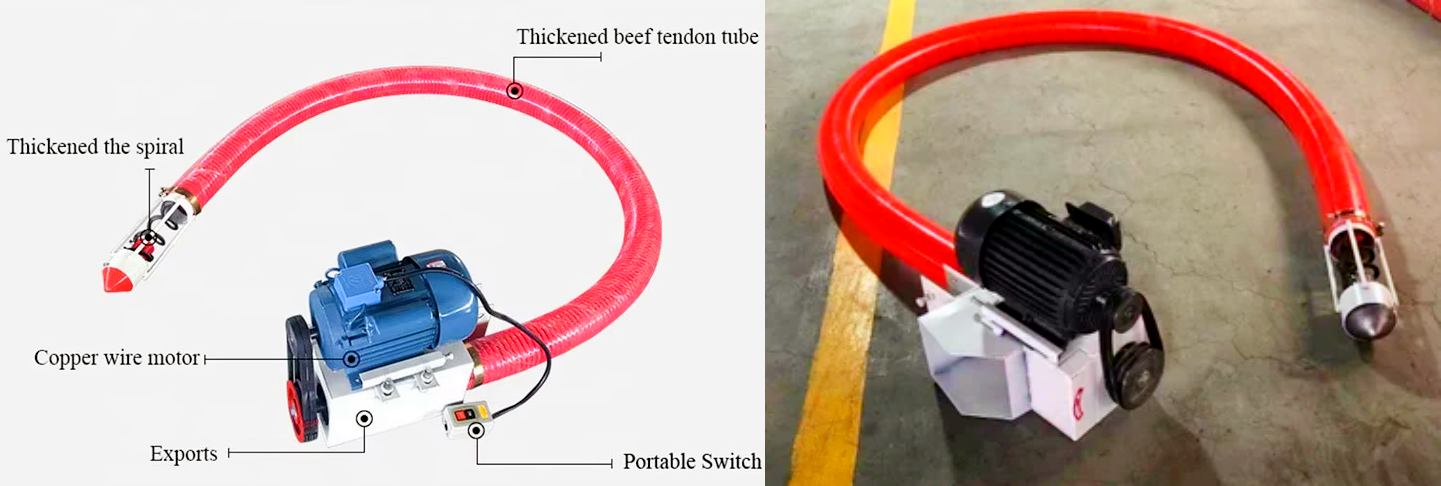

After the machine is started, the motor runs to drive the fan or pump to generate negative pressure.

The silica grain suction machine effectively processes and transfers silica grain particles through strong dust suction, particle separation and material transportation. The inhaled silica grain passes through the filter or dust collector, the larger particles are blocked, and the fine particles continue to flow.

The separated silica grain is transported to the designated location or storage container through the conveying pipe or trough.

What are the disadvantages of the silica grain suction machine?

Adaptability is limited by particle characteristics: Silica grain suction machines have certain requirements for the shape, humidity and particle size of particles when sucking materials. If the silica grain particles contain more moisture or larger particles, insufficient suction or blockage will occur. For overly wet or sticky materials, the suction effect may be limited.

Limited processing capacity: Although silica grain suction machines have different specifications and models, each device has its specific processing capacity limit. For large-scale silica grain production companies, if the amount of silica grain to be processed is very large, multiple suction machines are required to operate simultaneously, which will increase equipment investment and floor space.

Sensitive to material humidity: If the humidity of silica grain is high, particles are easy to stick together, and fine powder is also easy to agglomerate, which will affect the adsorption and screening effect of the suction machine. High humidity may also cause fine powder to block the filter element, increase the operating resistance of the equipment, and may even require frequent shutdowns for cleaning.

Energy consumption problem: Silica grain suction machines rely on equipment such as fans to generate negative pressure to absorb silica grain particles. Fans are usually powerful and consume a lot of electricity for a long time, resulting in high energy consumption costs. Especially when handling large amounts of silica grain, the energy consumption problem may be more obvious.

Parameters of silica grain suction machine

|

Pipe diameter |

length |

voltage |

power |

efficiency |

weight |

|

100mm |

3m |

220V |

3KW |

5-6 tons |

43kg |

|

100mm |

4m |

220V |

3KW |

5-6 tons |

47kg |

|

100mm |

5m |

220V |

3KW |

5-6 tons |

51kg |

|

100mm |

6m |

220V |

3KW |

5-6 tons |

55kg |

|

100mm |

7m |

220V |

3KW |

5-6 tons |

62kg |

|

100mm |

8m |

220V |

3KW |

5-6 tons |

66kg |

|

100mm |

9m |

220V |

3KW |

5-6t |

70kg |

|

100mm |

10m |

220V |

4KW |

5-6t |

74kg |

|

100mm |

11m |

380V |

4KW |

5-6t |

82kg |

|

100mm |

12m |

380V |

4KW |

5-6t |

86kg |

|

120mm |

3m |

220V |

3KW |

7-8t |

48kg |

|

120mm |

4m |

220V |

3KW |

7-8t |

52kg |

|

120mm |

5m |

220V |

3KW |

7 -8 tons |

56kg |

|

120mm |

6 meters |

220V |

3KW |

7-8 tons |

60kg |

|

120mm |

7 meters |

220V |

4KW |

7-8 tons |

60kg |

|

120mm |

8 meters |

220V |

4KW |

7-8 tons |

71kg |

|

120mm |

9 meters |

220V |

4KW |

7-8 tons |

75kg |

|

120mm |

10 meters |

220V |

4KW |

7-8 tons |

79kg |

|

120mm |

11 meters |

380V |

4KW |

7-8 tons |

89kg |

|

120mm |

12 meters |

380V |

4 KW |

7-8 tons |

93kg |

|

100mm |

20 meters |

380V |

7.5KW |

5-6 tons |

150kg |

|

100mm |

25 meters |

380V |

7.5KW |

5-6 tons |

170kg |

|

120mm |

20 meters |

380V |

7.5KW |

6-7 tons |

180kg |

|

120mm |

22 meters |

380V |

7.5KW |

6-7 tons |

200kg |

Application of silica grain suction machine

Material cleaning and recycling in silica grain production plants

The crushing, screening and cleaning of silica grain often produce a large amount of residual materials and dust. The silica grain suction machine can quickly absorb the scattered materials on the ground and around the equipment through negative pressure suction, and send them to the recovery bin for processing or reuse.

Silica grain screening and purification in the glass industry

In the glass production process, silica grain is an important raw material, which needs to be screened and purified with high precision to ensure the quality of glass. The silica grain suction machine can grade and convey the sieved silica grain particles to ensure uniform particles and avoid the influence of impurities on the quality of glass.

Silica grain recovery and cleaning in the foundry industry

Silica grain is used as a filling material for castings. After repeated use, the silica grain will be contaminated and need to be screened and recycled for reuse. The silica grain suction machine extracts the contaminated silica grain from the waste through pneumatic conveying, removes impurities and particles, and ensures that the quality of the sieved silica grain meets the standards.

Efficient transportation and storage of silica grain

In some places where a large amount of silica grain needs to be stored and transported, such as chemical plants, building materials plants, silica grain warehouses, etc., silica grain particle handling and storage problems are often encountered. During transportation, the suction machine ensures the integrity of the material and avoids the loss or leakage of materials in traditional transportation methods.

Silica grain screening and impurity removal in the chemical industry

Silica grain is used in the production of some fine chemicals, such as silicon compounds, semiconductor materials, etc. In order to ensure the purity of the product, the silica grain needs to be finely screened. The silica grain suction machine can remove impurities, fine particles and dust through screening, suction and purification to ensure the purity of silica grain.

Silica grain suction machine can efficiently and accurately process silica sand particles in the application scenarios of many industries, improve production efficiency and improve the working environment. If you have further questions about specific industries or application requirements, you can contact our customer service.