Srew Conveyor For Masterbatch

Wednesday May-28 2025 14:29:46

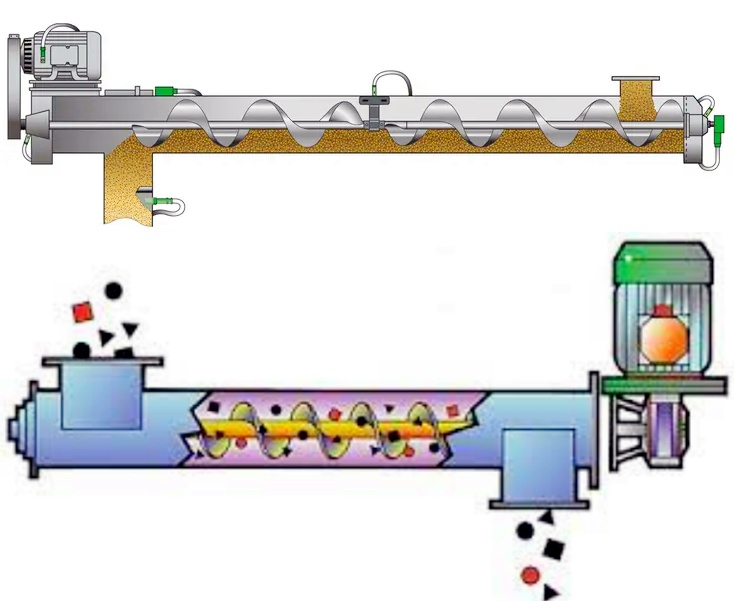

What is a screw conveyor for masterbatch

Masterbatch is a high-concentration colorant made by processing pigments,carrier resins and additives. It has the characteristics of fine particles, easy agglomeration, and large fluidity differences. Screw conveyor for masterbatch is a conveying equipment designed for its characteristics. The motor drives the screw shaft to rotate, and the thrust of the spiral blade is used to convey the masterbatch along the casing.

For masterbatches with fine particles and easy to generate dust, the equipment usually adopts a sealed tubular or U-shaped structure to effectively prevent dust from spilling out; and for masterbatches that are easy to agglomerate, its stirring function can disperse the material during the conveying process to ensure the uniformity of the conveying. With continuous and stable conveying effect, masterbatch screw conveyor can meet the needs of plastics, chemical fiber and other industries for quantitative and efficient conveying of masterbatch, and ensure the stability and consistency of product coloring quality.

What are the types of masterbatch screw conveyors?

According to the different structural forms and conveying directions, masterbatch screw conveyors can be mainly divided into the following three types: tubular screw conveyors, U-shaped screw conveyors and vertical screw conveyors, each of which is suitable for different process requirements.

1. Tubular screw conveyor

Structural features: It consists of a circular seamless steel pipe (shell) and a built-in screw shaft, with feed and discharge ports at both ends.

Applicable scenarios: dry granular materials, medium and low viscosity powder materials (such as conventional masterbatch particles, non-fiber masterbatch).

Conveying requirements: horizontal or inclined angle ≤20° conveying, conveying distance is generally ≤15 meters (long distance requires segmented driving).

2. U-shaped screw conveyor (trough type)

Structural features: The shell is a U-shaped trough, a cover plate can be added on the top, and the screw shaft is supported by an intermediate hanging bearing (for long distances).

Applicable scenarios: granular materials, fiber-reinforced masterbatches, high-viscosity or easily agglomerated materials (such as masterbatches containing resin matrices).

Conveying requirements: mainly horizontal conveying, which can be tilted slightly (≤15°), suitable for large production and frequent cleaning (such as when changing colors on the production line).

3. Vertical screw conveyor

Structural features: The screw shaft is installed vertically, the shell is a round straight tube, the feed port is at the bottom, and the discharge port is at the top. The spiral blade spacing is small, the speed is high (≥100r/min), and the centrifugal force and the weight of the material are used to achieve lifting.

Applicable scenarios: dry granular materials with good fluidity (such as injection molding masterbatches), not suitable for powder or high-viscosity materials (easy to clog).

Conveying requirements: vertical lifting height ≤8 meters, and horizontal feeding equipment (such as vibrating feeder) is required.

What is the working principle of screw conveyor for masterbatch?

The working principle of the screw conveyor is to use the rotating spiral blades to push the material forward along the direction of the spiral shaft. For granular or powdery materials such as masterbatch, when the spiral blade rotates in the cylinder or U-shaped groove, the friction between the material and the cylinder wall and the gravity of the material itself make the material rotate with the spiral and slide upward along the spiral surface, thereby realizing continuous conveying of the material.

Selection parameters of screw conveyor for masterbatch

|

Model |

Screw diameter (mm) |

Conveying length (m) |

Conveying capacity (m³/h) |

Motor power (kW) |

Structure type |

|

LS160 |

160 |

1~6 |

2~8 |

1.5~3 |

Tube type/sealed type |

|

LS200 |

200 |

1~8 |

3~12 |

2.2~4 |

Tube type/with hopper |

|

LS250 |

250 |

1~10 |

6~18 |

3~5.5 |

with quick-release structure |

Note: The specific parameters need to be customized based on factors such as conveying height, inclination, material stacking density, and operating frequency.

What can masterbatch screw conveyors be used for?

As a multifunctional conveying equipment, screw conveyors for masterbatch have extensive and critical applications in the plastic processing industry. They are mainly used to achieve accurate and efficient transmission and feeding of masterbatches. In the masterbatch production line, it can transport the produced masterbatches in granular or powder form from the cooling and screening process to the packaging area, or transfer them to the finished product silo to ensure the continuity of the production process.

Whether it is injection molding, extrusion, blow molding or granulation, the screw conveyor for masterbatch can stably and continuously transport masterbatches of different colors and models from the storage hopper or ton bag to the feed port of the main machine such as the injection molding machine and the extruder.

For occasions that require high-precision color matching and mixing, it is often used in conjunction with a loss-in-weight metering feeder or a volumetric feeder. By accurately controlling the screw speed, the precise addition of trace masterbatches can be achieved, thereby ensuring the color uniformity and product quality stability of the final plastic product. In addition, in some production layouts where masterbatches need to be lifted to high-level silos or across a certain distance, its ability to transport horizontally, inclined, or even vertically also plays an important role.

Screw Conveyor For Masterbatch Manufacturer

Dahan Machinery is a well-known manufacturer of vibrating screening and conveying equipment. Its product line includes screw conveyors and is able to provide solutions for the masterbatch industry. It usually provides a variety of models and customized services to meet the specific needs of different customers.

Different types of screw conveyors: tubular, U-trough, inclined, vertical, etc., to meet different conveying directions and environmental requirements.

Different materials: carbon steel, stainless steel, etc., selected according to the characteristics and hygiene grade requirements of the masterbatch.

Different blade forms: for particles with good fluidity or powder masterbatches that are easy to bond, provide suitable spiral blade designs.

Customized services: customized according to the customer's conveying volume, conveying distance, inlet and outlet design, connection with existing equipment, etc.

The screw conveyor for masterbatch continuously pushes the material through the rotating spiral blades, which can realize the closed conveying of masterbatch, avoid dust leakage and material loss, and at the same time, the conveying is stable, efficient, and not easy to be blocked. With its simple structure, efficient conveying, good sealing and other advantages, it has become an indispensable equipment in the plastic processing, chemical, food and other industries. According to actual needs, the tubular, U-shaped or vertical structure can be selected to adapt to different conveying distances, angles and space arrangements, and is widely used in masterbatch automatic feeding, batching and production line conveying systems.