What is a movable pipe joint for auger unloading

Saturday June-07 2025 17:11:28

What is a movable pipe joint for Auger Unloading?

A movable pipe joint for auger unloading is usually used at the discharge end of a screw conveyor (such as a tubular or shaftless screw conveyor) to connect, seal and flexibly adjust. It allows the pipeline to move or rotate within a certain range to adapt to installation requirements or reduce stress during equipment operation, while preventing material leakage.

In industrial production, it is often used to convey powdered, granular or small block materials. At the same time, in order to adapt to installation errors, equipment vibration, thermal expansion and contraction, or the need for regular disassembly and maintenance, it is necessary to use flexible connectors between the screw conveyor and other equipment (such as silos, pipelines, and next-level conveying equipment).

The role of the movable pipe joint for auger unloading

The role of the movable pipe joint for auger unloading is mainly reflected in the following aspects:

Connection and transition: The movable pipe joint is used as a connecting part between the outlet of the screw conveyor and the downstream pipeline or container to ensure that the material is smoothly discharged from the conveyor and enters the next link, playing the role of a transition bridge.

Flexible adjustment: Its movable design allows a certain angle of rotation or displacement, which can adapt to deviations during installation or slight vibrations during equipment operation, reduce pipeline system stress, and improve equipment adaptability.

Sealing and leakproof: The joint is usually equipped with a sealing ring to prevent powdery, granular or sticky materials from leaking during the unloading process, ensuring a clean operating environment and avoiding material loss.

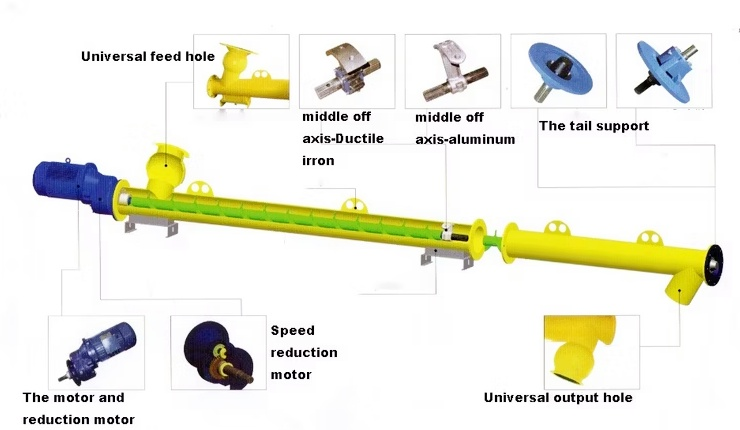

Structural composition of movable pipe joints for auger unloading

Spiral unloading movable pipe joints are equipment components used for bulk material transportation and unloading. They are usually used to connect conveying pipelines to unloading devices, such as screw conveyors or rotary valves. This type of joint allows a certain degree of flexibility and angle adjustment to compensate for installation errors or adapt to the needs of mobile unloading equipment.

Joint body: As the core component of the connection, it connects the discharge port of the screw conveyor with the downstream pipeline or container. Usually stainless steel, carbon steel or galvanized steel is used, depending on the material characteristics (such as corrosiveness or abrasiveness).

Moving parts: Allow the joint to rotate or adjust the angle within a certain range to adapt to installation deviations or equipment vibrations. It may include ball joints, universal joints or sliding sleeve designs to ensure flexibility.

Seals: Prevent material leakage and maintain the sealing of the unloading process. Commonly used are rubber seals, PTFE gaskets or silicone, which are resistant to high temperatures, corrosion or wear.

Connectors: Fix the joint to the discharge port or downstream pipeline of the screw conveyor. Including flanges, clamps, bolts or quick-release clamping devices.

When the screw shaft rotates, the power is transmitted to the conveying trough through the rotating joint, so that the material moves forward along the conveying trough. The movable pipe joints for auger unloading can realize axial and radial rotation, so that the screw conveyor can adapt to various complex working environments during the unloading process, and effectively prevent the material from wearing the screw shaft and the conveying trough.

Common specifications of movable pipe joints for auger unloading

|

Model |

Applicable pipe diameter (mm) |

Pipe length (mm) |

Material |

Temperature range (℃) |

|

HGT-150 |

150 |

200~300 |

PVC coated cloth |

-20~+80 |

|

HGT-200 |

200 |

250~400 |

Silicone cloth |

-40~+200 |

|

HGT-250 |

250 |

300~500 |

Polyurethane cloth |

-30~+100 |

What are the advantages of movable pipe joints for auger unloading in conveying equipment

Spiral unloading movable pipe joints have significant advantages in conveying equipment. Its structural design is flexible, which can realize dynamic connection between pipes, allow angular deviation and displacement within a certain range, effectively absorb vibration and thermal expansion stress during equipment operation, and reduce interference with equipment stability. At the same time, the joint has good sealing performance, prevents dust leakage during transportation, keeps the working environment clean, and reduces material loss. It is especially suitable for continuous transportation of bulk materials such as powder and granules.

What can the movable pipe joints for auger unloading be used for?

The movable pipe joints for auger unloading is mainly used at the discharge end of the screw conveyor to connect the discharge port with the downstream pipeline or container. Its flexibility and sealing make it play an important role in a variety of industrial scenarios.

Material conveying and unloading: smoothly transition the materials (such as powder, granules, and sticky materials) conveyed by the screw conveyor from the discharge port to the pipeline, storage silo or other equipment. Convey grain materials such as wheat, corn, and rice to prevent dust leakage; convey powdered chemical raw materials (such as fertilizers, plastic granules, and pigments); handle ore powder, coal powder, etc. to ensure that there is no leakage during the unloading process; convey flour, powdered sugar, starch, etc.

Sewage treatment and environmental protection equipment: In shaftless screw conveyors, it is used to transport viscous or irregular materials to designated containers or treatment equipment. In sewage treatment plants, it is used to transport dehydrated sludge or sediment, and the movable joint adapts to pipeline deviation and ensures sealing. It can handle domestic garbage or industrial waste, prevent odor or material spillage, and can also transport biomass materials such as wood chips and straw.

Movable pipe joints for auger unloading are widely used in industries such as chemical industry, food processing, agriculture (such as grain, feed), building materials (such as cement, fly ash), etc., and are important components to ensure smooth unloading and transmission of materials. If you have specific questions or need more detailed information, you can contact our customer service!