What is a stainless steel auger grain sucker

Tuesday August-05 2025 15:47:29

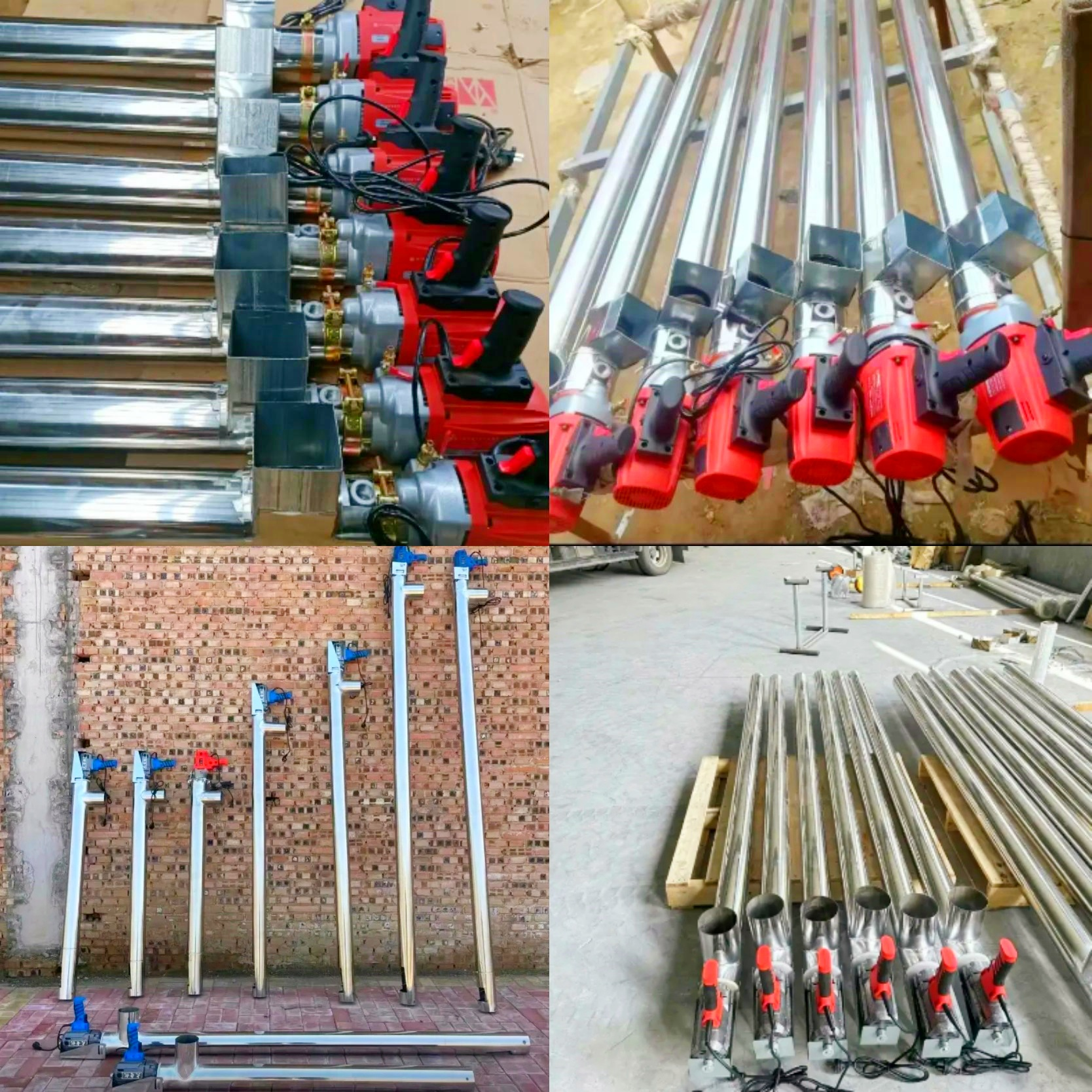

Stainless steel auger grain sucker is designed with both handheld and bracket modes. It can be flexibly operated by a single person, and can also be automated at a fixed workstation through the matching bracket. Its core component is a precision spiral conveying pipe with a standard pipe diameter of 100/150mm optional, and a conveying length of 3-6 meters that can be customized. It is driven by a variable frequency motor and has a conveying capacity of 2-5 tons/hour. The specially designed spiral blade structure can handle bulk grain, as well as convey standard grain bags or docking silo feed ports. The equipment is equipped with an intelligent control panel that can adjust the speed and conveying direction, and is equipped with anti-blocking sensors and overload protection devices. It is suitable for a variety of scenarios such as grain depots, farms, and processing plants, and can complete operations such as grain loading and unloading, emptying warehouses, and loading trucks, thereby reducing manual labor intensity.

The core reason for choosing a stainless steel auger grain sucker to convey materials is that its excellent material properties meet the high standards and high efficiency requirements of specific industries. When the conveyed materials are food (such as grain, flour, sugar), pharmaceutical excipients, precision chemical raw materials or high-end feed, the corrosion resistance of stainless steel is crucial. It can effectively prevent the equipment from rusting and contaminating the materials, ensuring the purity of the product.

Stainless Steel Auger Grain Sucker Video Show

Stainless steel auger grain sucker selection and classification

The selection of stainless steel auger grain suckers for grain conveying can be differentiated according to the material characteristics and damage requirements. For fragile grains such as corn, soybeans, and seeds, a stainless steel shaftless screw conveyor is recommended. Its center shaftless design can prevent grain crushing. If the grain allows for light mechanical contact, a stainless steel shafted screw conveyor can be selected. It has a simpler structure and lower cost. It is equipped with removable spiral blades for easy cleaning and is suitable for conveying hard grains such as rice and wheat. Shaftless stainless steel screw conveyors are suitable for working conditions where the integrity of the grain surface must be protected. Shafted stainless steel screw conveyors are suitable for situations where higher conveying speed and cost are required.

The difference between a stainless steel auger grain sucker and an ordinary grain sucker

Stainless steel auger grain sucker: It is suitable for situations where granular or powdery materials need to be conveyed stably and reliably, especially in situations where there are high requirements for cleanliness, such as food processing, pharmaceuticals and other industries. Due to its good sealing performance, it can reduce environmental pollution and is suitable for medium and short distances (within 6~12 meters). The conveying capacity is usually 3~15 tons/hour with high efficiency.

Ordinary grain sucker: It is more suitable for occasions that require long distances and flexible layout of conveying lines, such as material transfer between large warehouses, direct transportation from farms to processing plants, etc. It is particularly suitable for lightweight and fluid materials such as grains and flour. It can be conveyed horizontally, vertically, and inclined at multiple angles. It has strong adaptability and the conveying capacity is generally 1~8 tons/hour, which is moderate to low.

How does the stainless steel auger grain sucker work?

The stainless steel auger grain sucker mainly realizes the transmission of materials through the principle of spiral conveying.

The equipment is usually equipped with an electric motor as the driving source, and the high-speed rotation of the motor is converted into a low-speed and high-torque rotation suitable for the operation of the auger through a reducer. Driven by the motor, the spiral blade located in the stainless steel pipe begins to rotate, which can effectively push the material forward.

The material enters from the feed port of the equipment. As the spiral blade rotates, the material is pushed by the spiral blade to move along the pipeline direction. Due to the design of the spiral blade, it can effectively grasp and propel granular or powdered materials. Driven by the spiral blade, the material moves forward along the closed stainless steel pipe until it reaches the predetermined position (discharge port).

Application of stainless steel auger grain suction machine

Stainless steel auger grain suction machine is mainly used in the material conveying link in the grain, feed and food processing industries. In the grain depot, it is used to lift bulk wheat, corn and other grains from trucks or pits to silos, replacing traditional manual handling. It can handle 5-20 tons of grain per hour, which is particularly suitable for the emptying operation of small and medium-sized grain stations.

Feed mills often use it to convey pellet feed. The 304 stainless steel material avoids rust contamination. The spiral push method ensures the integrity of the feed, and the breakage rate is less than 0.3%. In the flour processing link, the auger conveys wheat from the cleaning screen to the mill, and the closed structure prevents dust from spilling. In the seed processing workshop, the low-speed auger can gently handle fragile seeds to avoid germ damage.

Common technical parameters of stainless steel auger grain sucker

|

Model |

pipe diameter (mm) |

conveying length (m) |

power (kW) |

conveying capacity (t/h) |

|

DTC-100 |

100 |

6 |

3 |

3-4 |

|

DTC-125 |

125 |

8 |

4 |

5-6 |

|

DTC-150 |

150 |

10 |

5.5 |

6-8 |

|

DTC-168 |

168 |

12 |

7.5 |

8-12 |

Online manufacturing of stainless steel auger grain sucker

At present, some stainless steel auger grain sucker manufacturers support online customized production, and the following parameters need to be understood:

Conveying length, height, output requirements;

Conveying material types (such as corn, wheat, pellet feed, etc.);

Detailed requirements such as pipe diameter and material (304 or 316).

Select according to your specific needs (conveying distance, material type, mobility)! If you need a specific model recommendation, you can tell us your usage scenario (such as hourly conveying volume, grain type, etc.).